Page 19

HORIZONTAL INSTALLATION (CONT.)

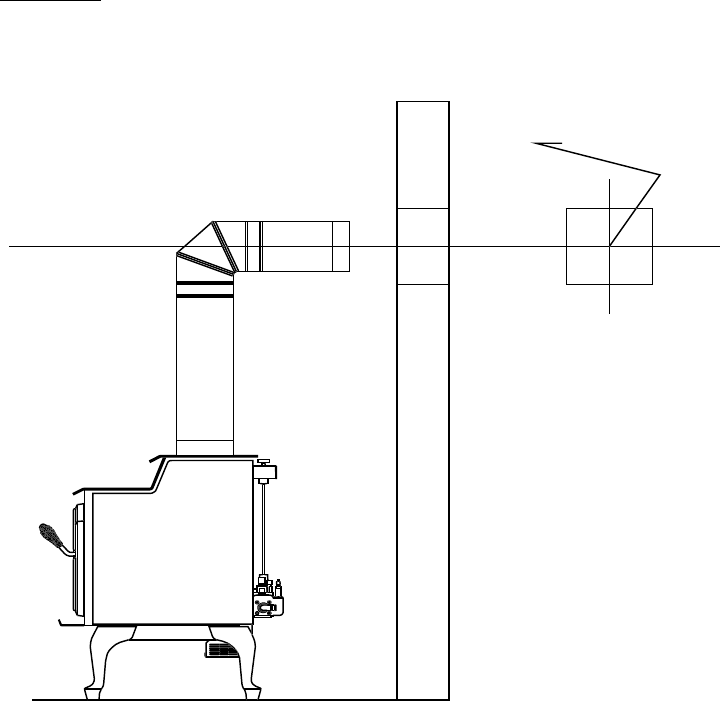

Step 3. With the adapter and pipe attached to the stove, slide the stove into its correct location, maintaining

minimum clearance to combustibles, and mark the wall for a 10” x 10” (254mm x 254mm) square

hole. The center of the square hole should line up with the centerline of the horizontal pipe, as

shown in Figure 6. Cut and frame the hole in the exterior wall where the vent will be terminated.

If the wall being penetrated is constructed of noncombustible material, i.e. masonry block or

concrete, a 7” (178mm) diameter hole is acceptable.

NOTE:

(1) The horizontal run of vent must be level, or have a ¼” (6mm) rise for every 1’ (305mm) of run

towards the termination. Never allow the vent to run downward. This could cause high temperatures

and may present the possibility of a fire.

(2) The location of the horizontal vent termination on an exterior wall must meet all local and national

building codes, and must not be easily blocked or obstructed.

(3) For installations requiring a vertical rise on the exterior of the building, 14” (356mm) and 36”

(914mm) tall snorkel terminations are available. Follow the same installation procedures as used

for standard horizontal terminations. If the snorkel termination must be installed below grade (i.e.

basement application), proper drainage must be provided to prevent water from entering the

snorkel termination. Do not backfill around snorkel termination.

NOTE: With proper vertical rise, refer to Venting Graph on page 15, up to four, 90 degree elbows may be

used.

Minimum vertical rise in a horizontal venting installation is 2’ (two feet). (See Venting Graph,

page 15.)

CENTER LINE

CENTER

LINE

CENTER OF HOLE

FIG. 6

Note: USE THE FOLLOWING

HORIZONTAL TERMINATION CAPS

ONLY!

1) Simpson DuraVentPart #985

OR

2) Aladdin Hearth Products Part

#HHW2