Page 18

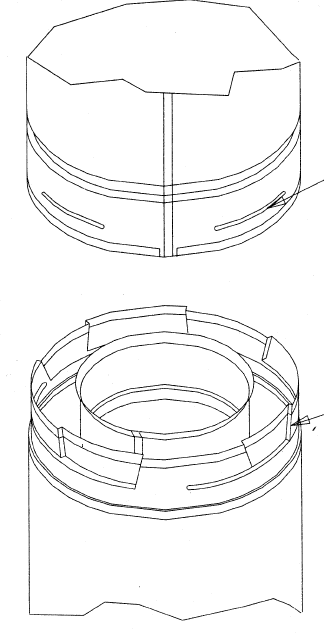

FIG. 5

FEMALE LOCKING LUGS

MALE LOCKING LUGS

HORIZONTAL INSTALLATION

NOTE: RESTRICTOR STRAP IS REQUIRED IF HORIZONTAL VENTING CONFIGURATION HAS 10’

OR GREATER OF VERTICAL RISE AND NOT MORE THAN ONE 90 DEGREE ELBOW.

Step 1. Set the gas stove in its desired location. Check to determine if wall studs or roof rafters are in the

way when the venting system is attached. If this is the case, you may want to adjust the location

of the stove.

Step 2. Simpson Dura-Vent pipe is designed with special twist-lock connections. To connect the venting

system to the stove flue outlet, a twist-lock adapter is built into the stove at the factory. Assemble

the desired combination of pipe and elbows to the adapter with pipe seams oriented towards the

wall or floor, as much out of view as possible. Remember to include wall thickness in minimum

clearances when figuring the measurements for your installation needs.

Note: Prior to joining pipes apply a high temperature silicone sealant with a rating of 500 degrees

Fahrenheit or greater to outside joint of vent pipe.

Twist-lock procedure: Four indentations, located on the female ends of pipes and fittings, are

designed to slide straight onto the male ends of adjacent pipes and fittings by orienting the four

pipe indentations so they match and slide into the four entry slots on the male ends (Figure 5).

Push the pipe sections completely together, then twist-lock one section clockwise approximately

one-quarter turn, until the two sections are fully locked. The female locking lugs will not be visible

from the outside, on the pipe or fittings. They may be located by examining the inside of the

female ends. There is a 1/4” rise per foot minimum on horizontal run.

NOTE: Horizontal runs of vent must be supported every 3’ (914mm). Wall straps are available for this

purpose. (See Parts List, pg. 12)