A. GENERAL

1. Read the Burner Instruction Manual, supplied with

the boiler or with the burner if purchased separately.

Review applicable code requirements for burner and

fuel piping installations.

2. Install piping to allow removal of burner and access

to combustion chamber for cleaning or service.

B. INSTALL FUEL OIL PIPING

1. Place the fuel oil tank and install the piping in

accordance with NFPA-31 and all other applicable

codes.

2. General Guidelines for Oil Piping

a) Follow the guidelines in the Burner Manual for

sizing oil lines. Never use smaller than 1/2" OD

copper tubing.

b) Install manual shut-off valves on the suction line

at the burner and at the oil line entrance to the

building. If installing a shut-off valve on the

return line, you must provide an oil pressure

relief valve piped ahead of the shut-off valve and

discharged to the tank to prevent over-pressure

conditions.

c) Install a two-pipe oil distribution system when

possible. It will improve the reliability of the oil

delivery to the burner.

d) Use flare fittings when using copper tubing.

e) Provide an oil line filter in the suction line. Size

the filter for the suction gear capacity of the

burner oil pump if running a two-pipe system.

f) If burner is above the top of the fuel oil tank,

install a check valve on the oil suction line at the

burner to prevent oil from evacuating the line. If

burner is below the top of the tank, install an

anti-siphon device to prevent oil flow should the

oil line break.

C. INSTALL GAS SUPPLY PIPING

1. Size the piping as required by the National Fuel Gas

Code, ANSI Z223.1 or as required by local codes.

a) Use Table 7.1 for sizing of natural gas for a

system pressure drop of 0.3 inch water column.

2. The standard gas train is designed for a maximum

pressure of 1/2 psig (14 inches water column). Make

sure the system regulator will not allow a higher

pressure to the Gas Control Train under any

conditions.

3. The minimum gas supply pressure is listed on the

Burner Rating Plate. Make sure the system regulator

and the piping are sized and adjusted properly to

provide this pressure under all conditions.

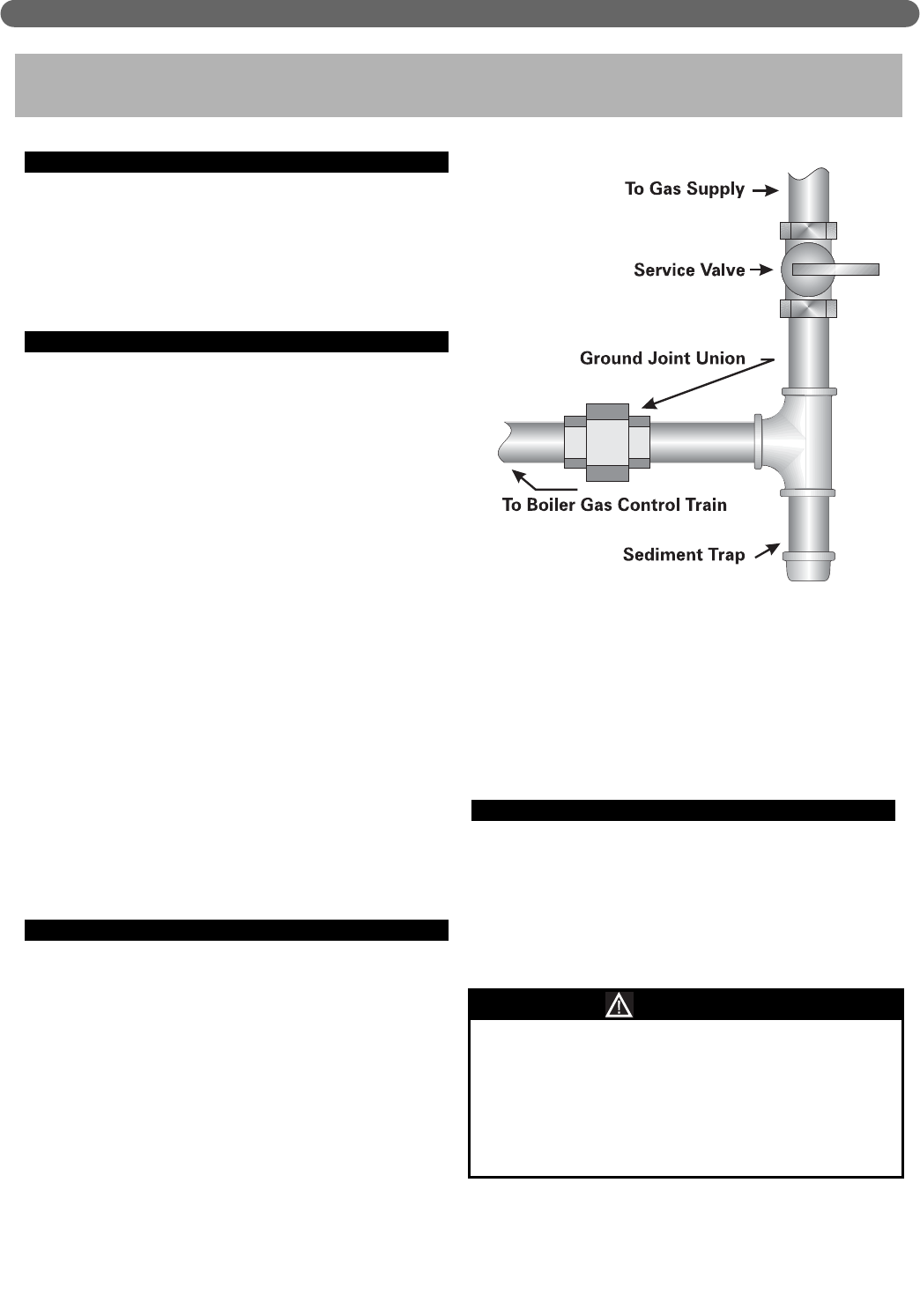

4. Install a Service Valve, Sediment Trap and Ground

Joint Union at the supply connection to the Gas

Control Train as shown in Figure 7.1. These are not

supplied with the boiler. Install them in accordance

with local codes.

5. Use only pipe joint compounds rated for use with

Liquefied Petroleum Gases.

D. TEST GAS SUPPLY PIPING

1. ISOLATE THE BOILER GAS CONTROL TRAIN

FROM THE SYSTEM DURING TEST:

a) Test pressure 1/2 psig or less – Close the Manual

Shut-Off Valve on the Boiler Gas Control Train.

b) Test pressure over 1/2 psig – Disconnect the gas

supply piping upstream of the Boiler Manual

Shut-Off Valve.

31

CONNECT FUEL PIPING

7. CONNECT FUEL PIPING

Figure 7.1: Gas Supply Connection to Boiler

Do not expose the Gas Control Train to excessive

pressure. The gas valves can be damaged. This could

result in explosion hazard and severe personal injury

or death.

Do not test gas supply piping with open flame. Use a

soap suds mixture brushed onto the pipe joints to

test for leaks.

WARNING