6

9. Pressure Relief Valve: The boiler pressure relief valve

is factory installed into the right side boiler manifold

(inside the jacket). Pipe the discharge of the relief

valve to within 12" of the floor and close to a floor

drain. Provide piping that is the same size or larger

than the relief valve outlet.

10. Circulator: The boiler circulator is to be sized to

overcome the pressure drop of the system while

providing the flow required by the boiler.

a. If the boiler is piped in a secondary loop of a

primary/secondary heating system, the circulator

will need only to overcome the resistance of the

boiler and any fittings in that loop.

b. The circulator should be sized based on the net

output of the boiler. The Table 3.2 shows the

Boiler Output as reported to the Hydronics

Institute division of GAMA. These values are

based on a pickup factor of 1.15.

WATER PIPING AND CONTROLS

Table 3.2 – Boiler Inputs and Outputs

Boiler

Model

Boiler Input

(Btu/hr [kW])

Net I=B=R Output

(Btu/hr [kW])

PI-T50 50,000 (14.7) 40,000 (11.7)

PI-T80 80,000 (23.4) 64,000 (18.8)

PI-80 80,000 (23.4) 64,000 (18.8)

PI-140 140,000 (41.0) 112,000 (32.8)

PI-199 199,000 (58.3) 159,000 (46.6)

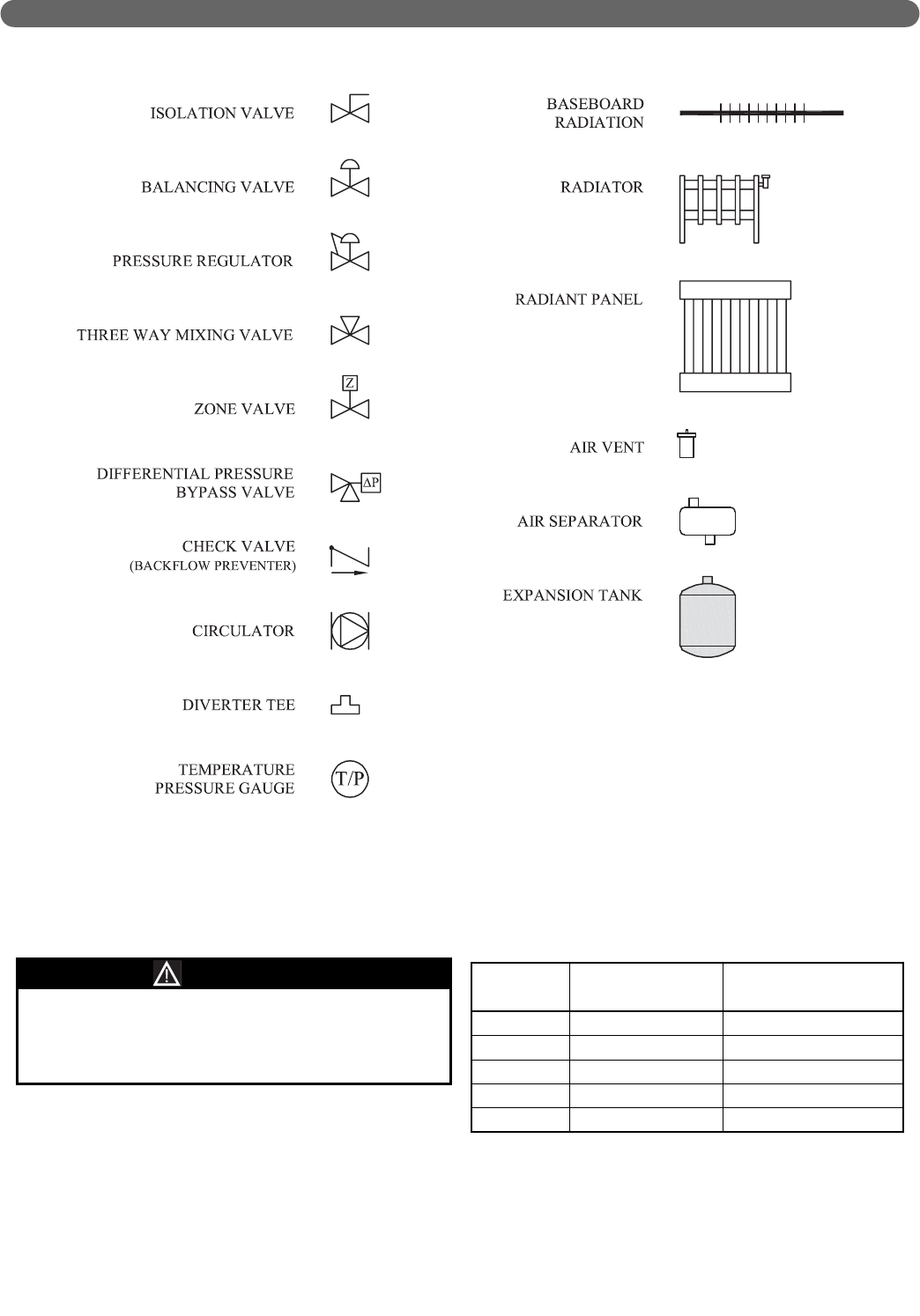

Figure 3.1: Piping Symbol Key

Pipe the discharge of the relief valve as close as

possible to the floor and away from high traffic areas.

Pipe the discharge to a floor drain. Failure to do so

may result in personal injury and/or property damage.

CAUTION