33

A. BOILER ERROR

1. When an error condition occurs the controller will

display an error code on the display module.

2. These error codes and several suggested corrective

actions are included in Table 8.1.

3. In the case of E00, E13, and E14 this error, if

uncorrected, will go into a fault condition as

described is Paragraph B.

B. BOILER FAULT

1. When a fault condition occurs the controller will

illuminate the red "fault" indication light and display

a fault code in the format "F##" on the display

module.

2. Note the fault code and refer to Table 8.2 for an

explanation of the fault code along with several

suggestions for corrective actions.

3. Press the reset key to clear the fault and resume

operation. Be sure to observe the operation of the

unit to prevent a recurrence of the fault.

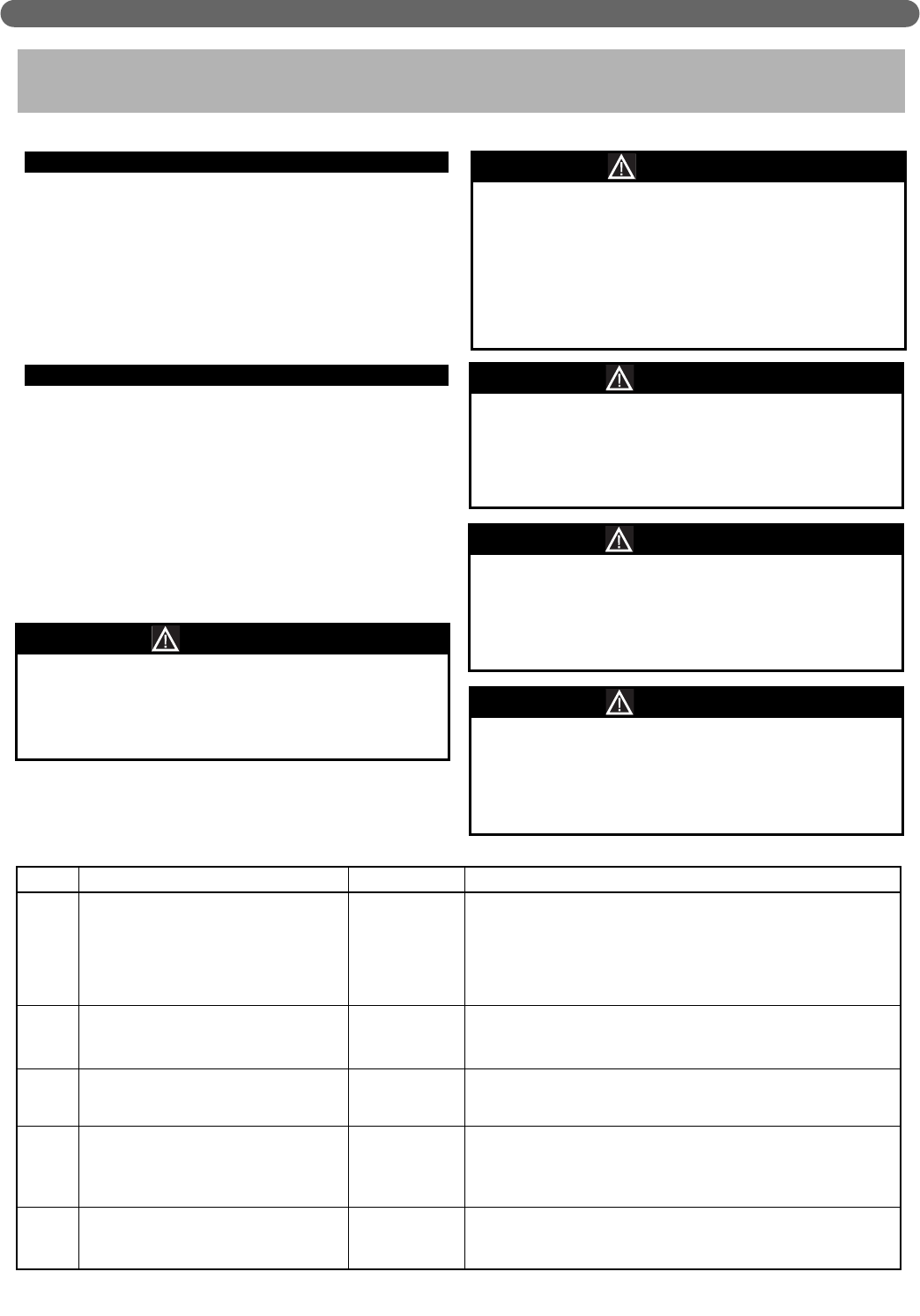

8. TROUBLESHOOTING

TROUBLESHOOTING

If overheating occurs or the gas supply fails to shut

off, do not turn off electrical power to the circulating

pump.This may aggravate the problem and increase

the likelihood of boiler damage. Instead, shut off the

gas supply to the boiler at the gas service valve.

CAUTION

This appliance has wire function labels on all internal

wiring. Observe the position of each wire before

removing it.Wiring errors may cause improper and

dangerous operation. Verify proper operation after

servicing.

CAUTION

DANGER

When servicing or replacing components that are in

direct contact with the boiler water, be certain that:

●●

There is no pressure in the boiler. (Pull the

release on the relief valve. Do not depend on

the pressure gauge reading).

●●

The boiler water is not hot

●●

The electrical power is off

When servicing or replacing any components of this

boiler be certain that:

●●

The gas is off.

●●

All electrical power is disconnected

WARNING

Do not use this appliance if any part has been under

water. Improper or dangerous operation may result.

Contact a qualified service technician immediately to

inspect the boiler and to repair or replace any part of

the boiler which has been under water.

WARNING

Code Description Duration Corrective Action

E00 High Limit Exceeded 50 Sec.

1. Check circulation pump operation.

2. Assure that there is adequate flow through the boiler by

accessing the status menu and assuring that there is less

than a 50°F rise from the return thermistor to the supply

thermistor.

3. Replace switch if faulty.

E13

Combustion Fan Speed Low.

The boiler combustion air fan speed

less than 70% of expected.

60 Sec.

1. Check the combustion air fan wiring.

2. Replace the combustion air fan.

3. Replace the control board.

E14

Combustion Fan Speed High.

The boiler combustion air fan speed

is more than 130% of expected.

60 Sec.

1. Check the combustion air fan wiring.

2. Replace the combustion air fan.

3. Replace the control board.

PRO Water Pressure Switch Open Until Corrected

1. Assure that the system pressure is above 10 psig.

2. Check for leaks in the system piping.

3. Check the switch operation by applying a jumper. (If the

switch is not functioning properly replace it.)

FLu Blocked Vent Pressure Switch Open Until Corrected

1. Assure that the vent is not blocked.

2. Check the switch operation by applying a jumper. (If the

switch is not functioning properly replace it.)

Table 8.1: P125 Control Board Error Codes