21

4. The minimum combined equivalent length is 16

equivalent feet.

5. The maximum combined equivalent length can be

extended by increasing the diameter of the vent

pipe. However, the transitions should begin a

minimum of 15 equivalent feet from the boiler.

a. Transitions should always be made in vertical

sections of pipe to prevent the condensate from

pooling in the vent pipe.

b. Use a 3" x 2" reducing coupling to transition from

the PI-T50 and PI-T80 boiler connections to a 3"

vent.

c. Use a 4" x 3" reducing coupling to transition from

the PI-80, PI-140, and PI-199 boiler connections

to 4" vent.

d. The maximum equivalent length for the

increased diameter vent pipes is 125 feet.

e. If the transition occurs at a distance greater than

15 equivalent feet from the boiler, the maximum

equivalent length will be reduced. See Table 5.2.

Standard Vent Pipe is 2” and Oversized Vent

Pipe is 3” for PI-T50 and PI-T80. Standard Vent

Pipe is 3” and Oversized Vent Pipe is 4” for PI-

80 through PI-199.

E. EXHAUST VENT AND AIR INTAKE PIPE

INSTALLATION

1. On the PI-T50 and PI-T80 the 2" exhaust vent

connection is located on the top, right side of the

boiler and the air intake is on the top, left side. See

Figure 10.1. The air intake connection is intended

for a slip fit. No sealant or adhesive is required.

2. On the PI-80, PI-140, and PI-199 Boilers the 3”

exhaust vent connection is located on the rear of the

boiler and the air intake is higher and toward the left

side when the boiler is viewed from the front. See

Figure 10.2. The air intake connection is intended for

a slip fit. No sealant or adhesive is required.

3. Use only solid PVC, CPVC, or ABS schedule 40 or

80 pipe. FOAM CORE PIPING IS NOT APPROVED.

4. Remove all burrs and debris from joints and fittings.

5. All joints must be properly cleaned, primed, and

cemented. Use only cement and primer approved for

use with the pipe material. Cement must conform to

ASTM D2564 for PVC or CPVC pipe and ASTM

D2235 for ABS pipe.

6. Horizontal lengths of exhaust vent must slope back

towards the boiler not less than ¼" per foot to allow

condensate to drain from the vent pipe. If the vent

pipe must be piped around an obstacle that causes a

low point in the pipe, a drain pipe must be

connected to allow condensate to drain.

7. All piping must be fully supported. Use pipe hangers

at a minimum of 4 foot intervals to prevent sagging

of the pipe where condensate may form.

8. Do not use the boiler to support any piping.

9. A screened straight coupling is provided with the

boiler for use as an outside exhaust termination.

10. A screened inlet air tee is provided with the boiler to

be used as an outside intake termination.

11. The following are optional intake air/exhaust vent

terminations available from your PB Heat, LLC

distributor for use with Pinnacle boilers.

12. Refer to Figure 5.3 to 5.10 for sidewall venting and

Figures 5.11 to 5.14 for vertical venting.

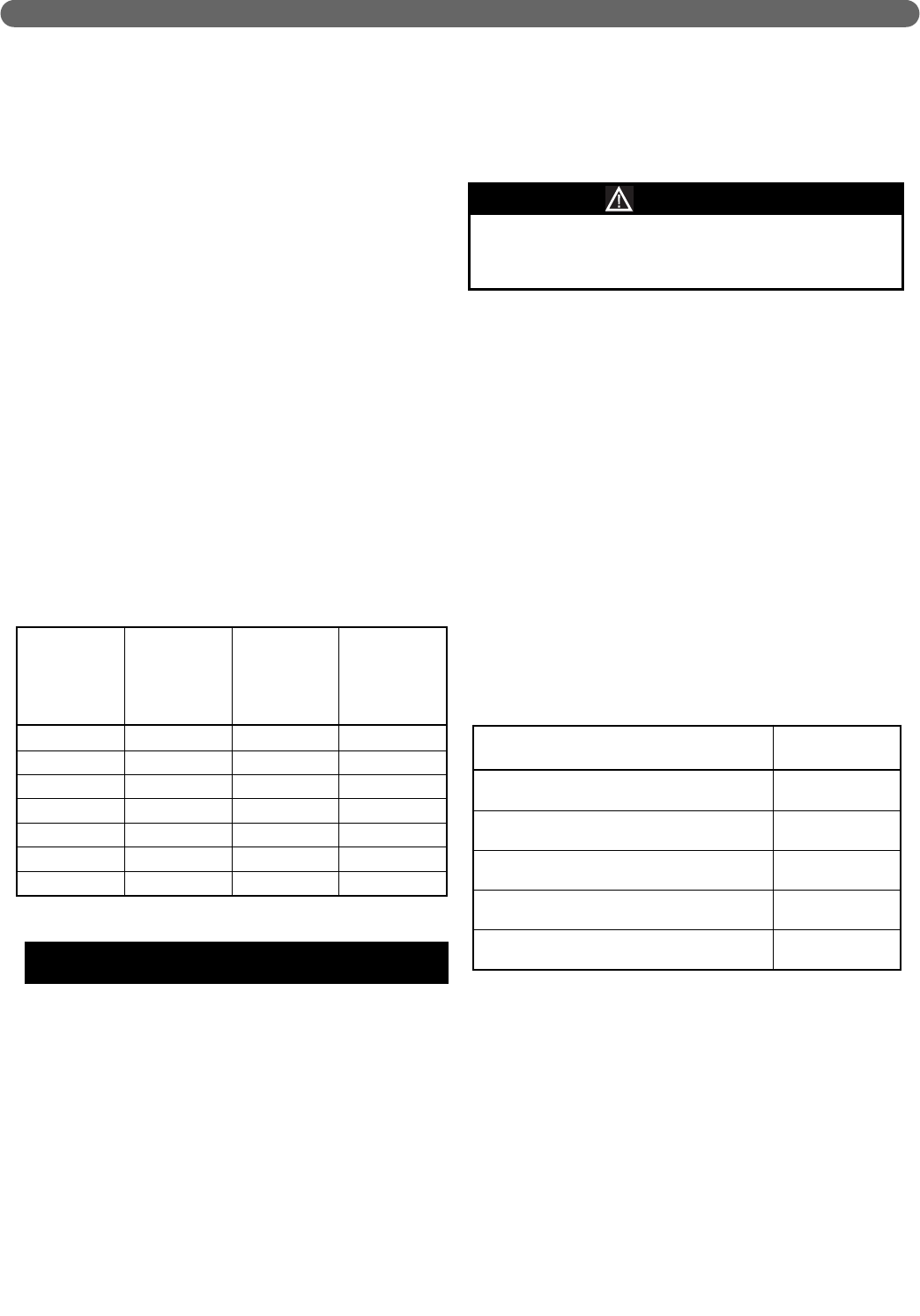

VENTING, INLET AIR AND CONDENSATE

Description

Stock

Code

2" PVC Concentric Vent Termination Kit 91469

3" PVC Concentric Vent Termination Kit 91403

2" Stainless Steel Vent Termination Kit 91465

3" Stainless Steel Vent Termination Kit 91402

4" Stainless Steel Vent Termination Kit 91401

Table 5.3: Vent Termination Kits

All joints of positive pressure vent systems must be

sealed completely to prevent leakage of flue products

into the living space.

WARNING

Transition

Point

(ft from

boiler)

TEL of

Standard 2”

or 3” Vent

Pipe (ft)

TEL of

Oversized 3”

or 4” Vent

Pipe (ft)

Maximum

TEL of all

Vent Pipe (ft)

15 30 95 125

20 40 77-1/2 117-1/2

25 50 60-1/2 110-1/2

30 60 43 103

35 70 26 96

40 80 8-1/2 88-1/2

None 85 0 85

Table 5.2: Maximum Equivalent Vent Length for

Oversized Vent Pipe

TEL = Total Equivalent Length