17

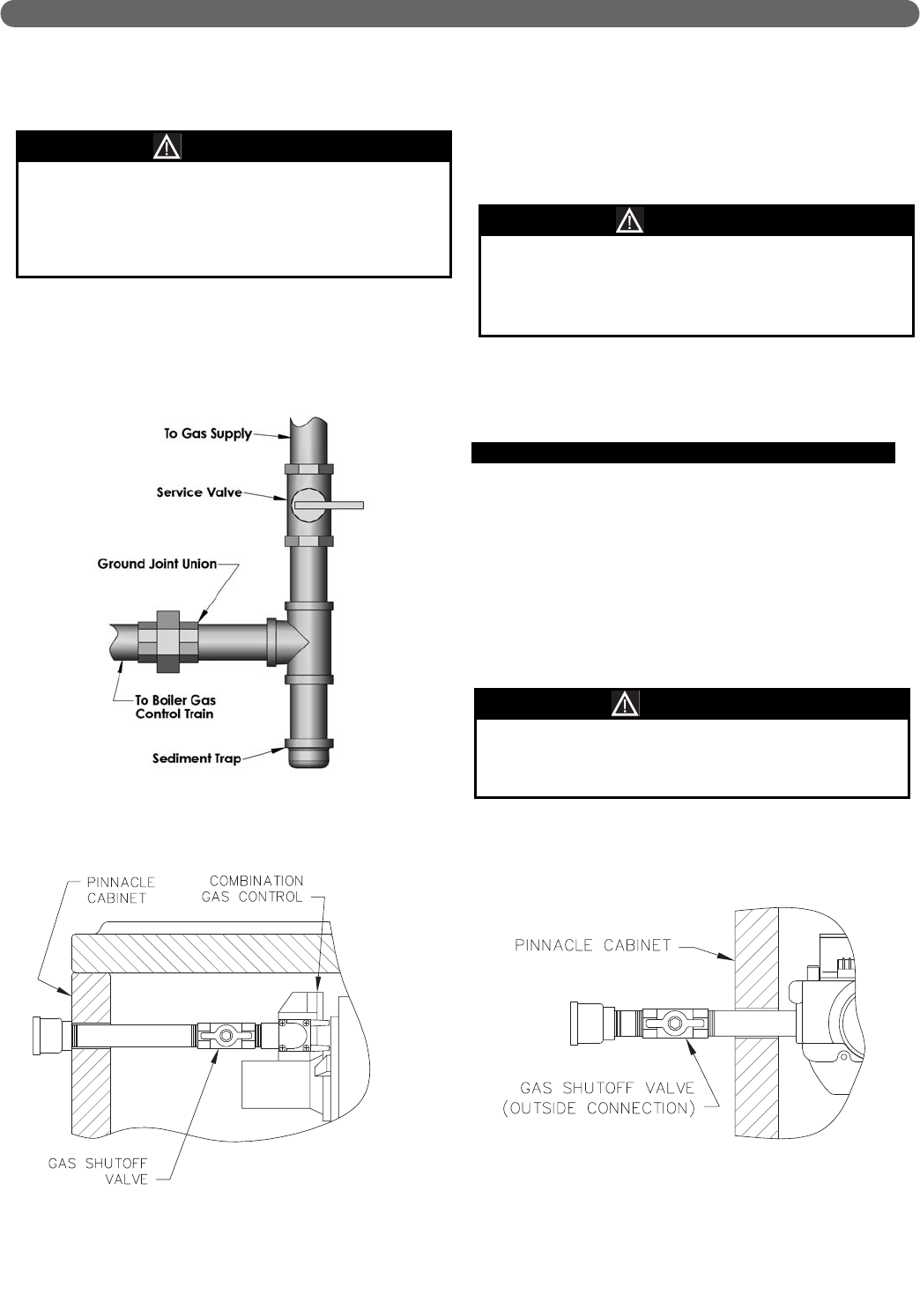

2. Install a sediment trap as shown in Figure 4.1. Be

sure to allow clearance from the floor for removal of

the pipe cap.

3. Install a ground joint union between the sediment

trap and the boiler to allow service of the appliance.

4. Install a service valve as shown in Figure 4.1 to allow

the gas supply to be interrupted for service.

5. Maintain a minimum distance of 10 feet between the

gas pressure regulator and the boiler.

6. Check all gas piping for leaks prior to placing the

boiler in operation. Use an approved gas detector,

non-corrosive leak detection fluid, or other leak

detection method. If leaks are found, turn off all gas

flow and repair as necessary.

7. Figure 4.2 and 4.3 are illustrations of the gas shutoff

valve for the Pinnacle Boiler. This valve is to be used

in addition to the gas service valve shown

in Figure 4.1.

D. GAS SUPPLY PIPING - OPERATION

1. The gas line must be properly purged of air to allow

boiler to operate. Failure to do so may result in

burner ignition problems.

2. Table 4.4 shows the maximum and minimum supply

pressure to the boiler.

a. Gas pressure below the minimum pressure may

result in burner ignition problems.

b. Gas pressure above the maximum may result in

damage to the gas valve.

GAS PIPING

Do not subject the gas valve to more than 1/2 psi

(13.5" W.C.) of pressure. Doing so may damage the

gas valve.

CAUTION

Use a pipe joint sealing compound that is resistant to

liquefied petroleum gas. A non-resistant compound

may lose sealing ability in the presence of this gas,

resulting in a gas leak. Gas leaks may potentially

cause an explosion or fire.

WARNING

When checking for leaks, do not use matches,

candles, open flames or other methods that provide

an ignition source.This may ignite a gas leak

resulting in a fire or explosion.

WARNING

Figure 4.1: Gas Supply Piping – Sediment Trap

Figure 4.2: PI-80/PI-140/PI-199

Gas Valve Shut Off

Figure 4.3: PI-T50/PI-T80 Gas Valve Shut Off