26

ELECTRICAL

Install all electrical wiring in accordance with the National

Electrical Code, ANSI/NFPA 70, and local requirements.

A. WIRING

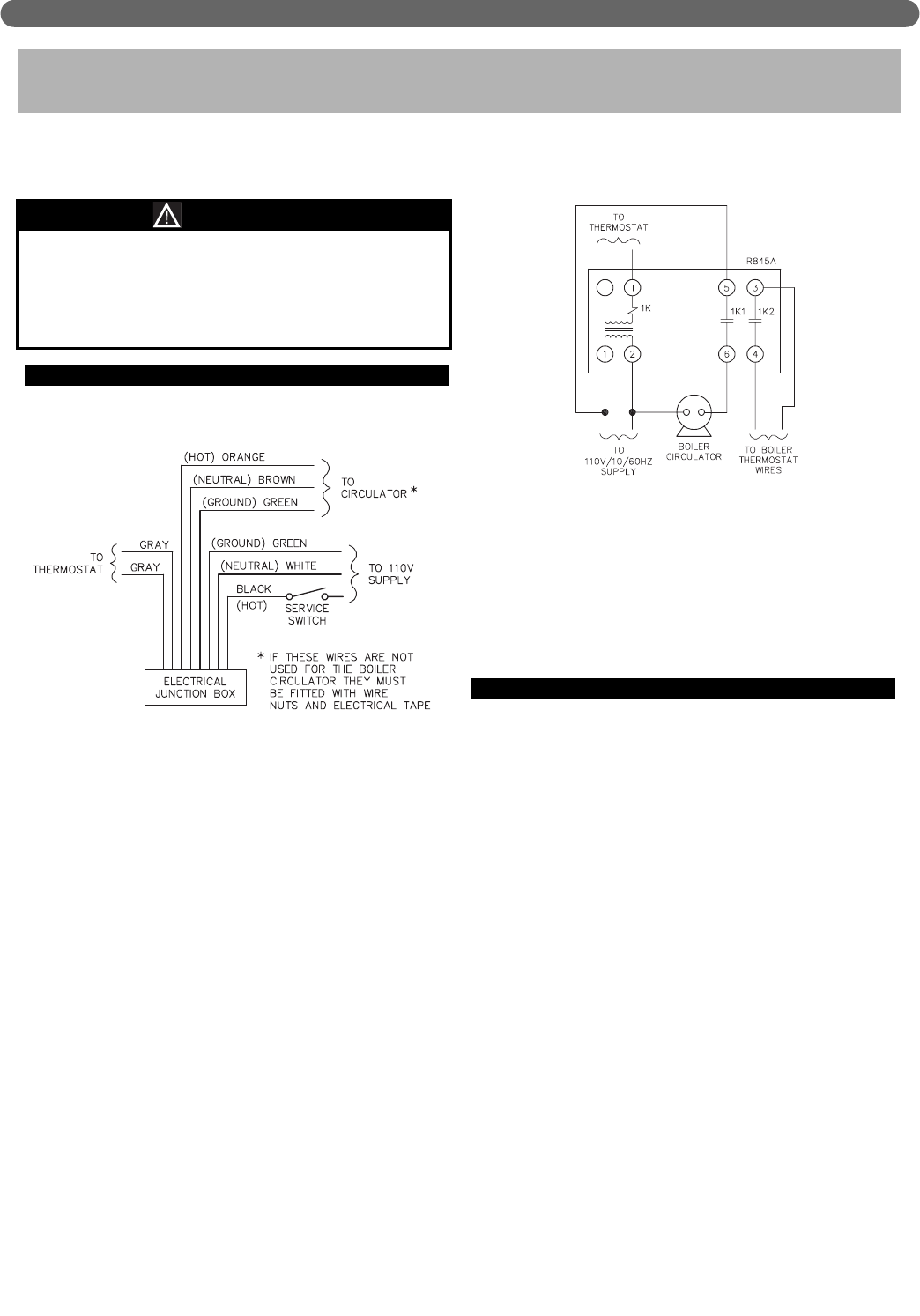

1. Refer to Figures 6.1 for connecting the power supply

to the boiler.

2. Connect boiler to a 110 volt, single phase, 60 hertz

electrical supply line with a fused disconnect switch.

The boiler is fused for a load of 6.3 amperes.

3. The boiler electrical connection is located on the left

side of the boiler in the junction box which houses

the service switch.

4. Wire the burner service switch in the hot line to the

boiler as shown in Figure 6.1.

5. Make sure to maintain correct polarity on the

incoming power supply wires. If polarity is reversed,

the boiler control will not sense the main burner

flame.

6. Connect the ground wire from the incoming power

supply to the green ground screw in the junction

box. Also, the boiler ground should be connected to

this screw.

7. Figure 6.1 shows connections to system circulator.

a) The maximum current load for the circulator

circuit is 4.0 amperes.

b) For loads greater than 4.0 amps, isolate the

circulator using a switching relay.

c) An example of this wiring using a Honeywell R845A

relay is shown in Figure 6.2

8. The thermostat connections are shown in Figure 6.1

or 6.2. The setting for the thermostat anticipator is

0.56 amps.

9. The boiler control board and factory wiring are

shown in figure 6.3.

B. SEQUENCE OF OPERATION

1. System Power-Up:

a) When power is first applied to the boiler, the

control will initially run through a self-diagnostic

routine. The interface unit shows the system

supply temperature.

b) Next, it will power the combustion air fan for a 10

second purge cycle.

c) Finally the combustion air shuts down and if there

is no call for heat the control board enters a

standby mode.

2. Heating Cycle:

a) When the thermostat calls for heat (closing the

contact between the two gray [TT] wires) and the

boiler control senses a supply temperature lower

than the set point by more than the differential,

the boiler initiates a heating cycle.

b) The control then powers the combustion air fan

at the speed prescribed for the particular boiler

model and performs a 6 second pre-purge of the

combustion chamber.

c) 0.5 second before the pre-purge is complete

power is applied to the spark igniter.

d) Once the pre-purge cycle is complete, the fan

speed decreases to the programmed ignition

speed.

6. ELECTRICAL

This unit when installed must be electrically

grounded in accordance with the requirements of the

authority having jurisdiction or, in the absence of

such requirements, with the current edition of the

National Electrical Code, ANSI/NFPA 70.

NOTICE

Figure 6.1: Wiring Connections to Boiler

Junction Box

Figure 6.2: Wiring Circulator with R845A

Switching Relay