3.2 Selecting Tubing

Select a tubing material and size that is right for your application (the fluid and

flow rate that you are pumping).

Table 9-2 in Chapter 9, shows the average flow rates for different size tubing.

Normalized flow rates (mL per revolution) vary significantly, based on motor

speed, tubing materials, viscosity, and mechanical tolerances in pump dimensions.

Table 9-3 outlines the variances resulting from differences in motor speed, tubing

materials, and mechanical tolerances. Table 9-6 outlines the variances due to

differences in viscosity.

To determine the chemical compatibility of a particular tubing material, it is

recommended that you test the tubing under actual conditions.

Tubing materials that can be used include Vinyl, Viton, Tygon, Silicone,

Santoprene, and Norprene. Up to 68 durometer tubing can be used.

Poor tubing life results were obtained for

5

⁄16" (8.0mm) inner diameter

Santoprene tubing. This particular tubing should not be used with the

pump motor.

3.3 Tubing Life

Over time and high speeds, flow rates will drop as the tubing wears out. Tubing

life for various materials and sizes are shown in Table 9-4 in Chapter 9. Tubing

should be periodically inspected for wear. Either move the tubing to a fresh

section, or replace tubing entirely (refer to Section 3.4).

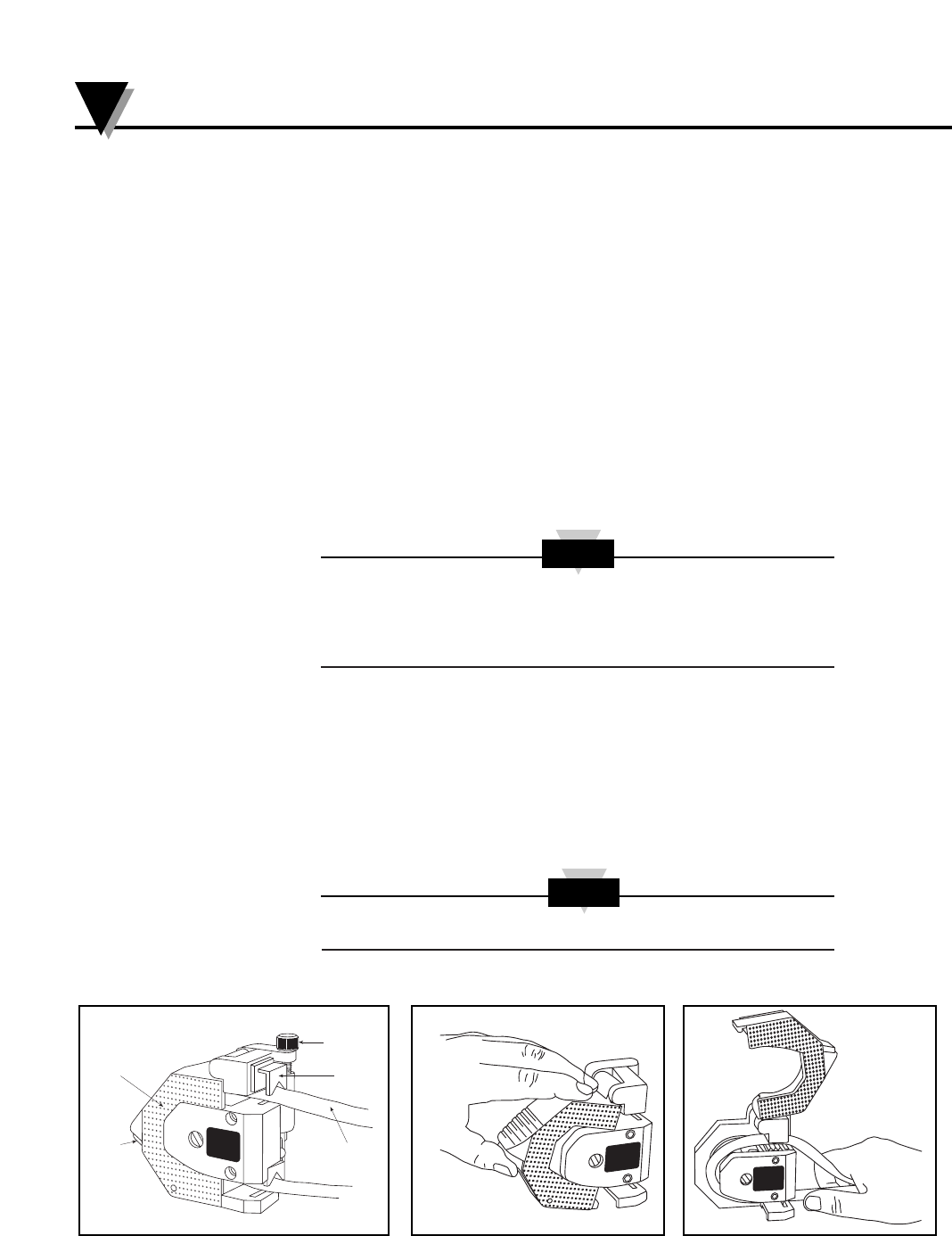

3.4 Loading the Tubing

Perform ALL of the steps in Chapter 3 before turning the motor on.

Follow this procedure (refer to Figures 3-8 through 3-12):

Figure 3-8. Parts of the Pump Figure 3-9. Opening the Stator Figure 3-10. Loading the Tubing

Clamp

Screw

Stator

Latch

Tubing

Clamp

Plate

Getting Started

3

3-4

NOTE

CAUTION