This feature will reduce the possibility of corrosion

of the electrodes and the possible accumulation of

algae and bacteria growing in the cylinder.

BUILT ON AND REMOTE MOUNTED

BLOWER PACKS (BOBP’s / RMBP’s)

FAN MOTOR OILING: The blower pack fan motor

requires occasional oiling of motor bearings. To do

this, open up the blower pack top and oil the motor

with ten drops of SAE-20 grade motor oil. Refer to

Figure #6 for oiling slots. It is important to oil the fan

motor every four months to preserve long life and to

maintain the fan’s warranty. It is not necessary to

disassemble the fan/motor assembly. The exploded

view is for visual purposes only.

TROUBLESHOOTING

PLEASE READ THIS SECTION BEFORE

REFERENCING SPECIFIC DIAGNOSTIC

MESSAGES.

1. Ensure the installation detail conforms with the

recommendations contained in the Installation

Manual, Form #XX-161.

2. Understanding the Principle of Operation is an

asset when troubleshooting. This information is

readily available from your local representative.

3. When contacting your local representative or

NORTEC, for troubleshooting assistance, please

ensure the serial number has been obtained for

reference purposes.

4. Whenever the troubleshooting steps indicate a

problem with the main pc-board, first check all

connections at the main pcb (including the ribbon

cable connections at the center of the main pcb)

before ordering replacements.

STARTING POINT

If nothing is working, check for 24 VAC output

from the stepdown transformer (see wiring diagram).

If there is no 24 VAC output, the transformer might

have been damaged if external controls were installed

and/or connected with the field-supplied fused

disconnect on. If this is the case, the transformer must

be replaced.

The conductivity of the water within the cylinder

must be controlled, in order for the humidifier to

function properly. The fill and drain rates must be

maintained. Filling too quickly can cause over-amping

and automatic shutdown or blown fuses. Filling too

slowly can cause insufficient steam output and

humidity levels. Water supply pressure should be

between 30 and 80 psig, ideally 55 to 60 psig.

Draining too slowly can cause over-concentration and

malfunction due to foaming. These are just some

examples of what can go wrong if the fill and drain

rates are not maintained.

Fill rates of suspect units should be checked.

Open the disconnect to cut off all power in the

humidifier before reaching inside. One of the 24VAC

wires to each primary voltage contactor holding coil

(some models have two contactors per cylinder)

should be temporarily disconnected for this test. This

way, no boiling occurs during the test so as not to

detract from the fill rate. Fill rates should measure

nominally at 1" to 1-1/2" of vertical rise in water level in

the cylinder in one minute.

If filling too quickly, check for excessively high

supply water pressure (over 80 psig). If water

pressure is correct, verify fill valve body orifice (consult

factory). If filling too slowly, look to probable causes

described under Error 3 later in this manual. Check

rate with steam line disconnected.

Manual drain rates of suspect units should be

checked using Figure #18 as reference times.

If time measurements are longer, repeat with

external drain disconnected (and draining into a pail)

to know if external drain is impeding flow.

Clogged strainer and/or clogged drain valve will

cause shortened cylinder life. But start by determining

what caused the strainer and/or drain valve to clog in

the first place.

Do not assume that if strainer and/or drain valve

are clogged that they are to blame. If the external

drain has been impeding flow, then waste

accumulates, resulting in a clogged strainer and/or

clogged drain which, in turn, results in shortened

cylinder life.

-15-

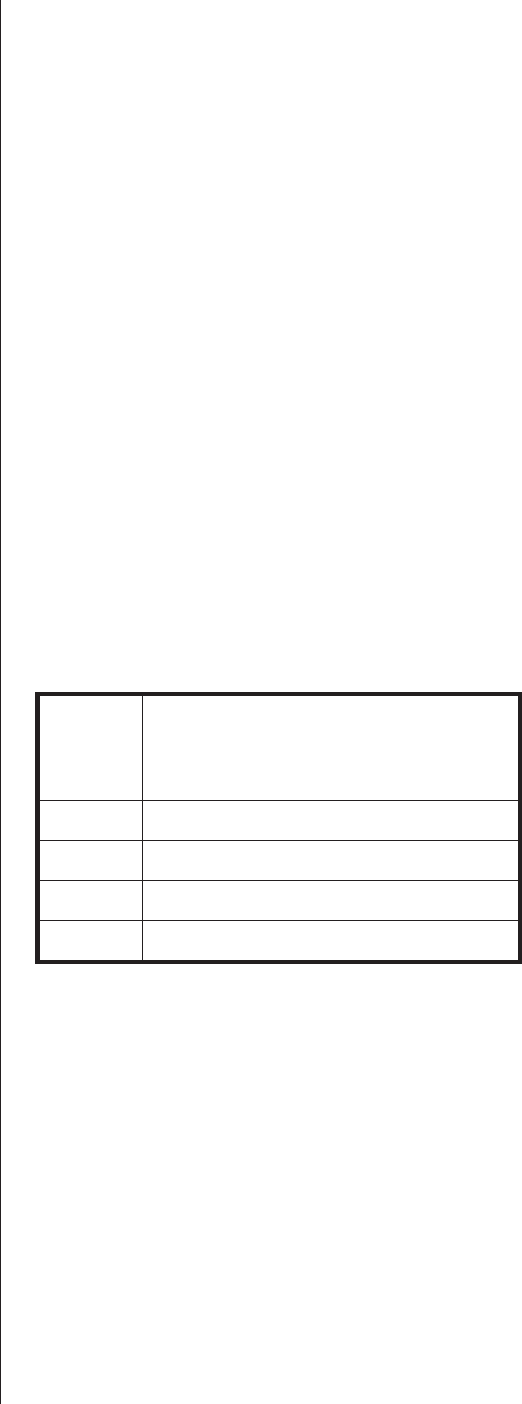

CYL. SIZE

(SERIES)

PROPER TIME (sec) TO DRAIN MANUALLY

FROM SEAM TO EMPTY

BEIGE BODY DRAIN VALVE

500/600 2 minutes and 52 seconds ± 10 sec.

400 1 minute and 20 seconds ± 5 sec.

300 43 seconds ± 2 sec.

200 25 seconds ± 1 sec.

Figure #18

Manual Drain Times