45

GAS-FIRED BOILER Boiler Manual

A. GAS CONNECTION

The gas supply shall have a maximum inlet

pressure of less than 14" water column (350

mm), ½ pound pressure (3.5 kPa), and a mini-

mum of 3.5" water column. The entire piping

system, gas meter and regulator must be sized

properly to prevent pressure drop greater than

0.5" as stated in the National Fuel Gas Code. This

information is listed on the rating plate.

The nipple provided is ½" with a factory installed

3/4" bell reducer. Do not remove this ¾" x ½" bell

reducer! It is mandatory that this fitting is used

for connection to a field fabricated drip leg as

shown in the illustration above per the National

Fuel Gas Code. You must ensure that the entire

gas line to the connection at the Munchkin is no

smaller than ¾". Once all the inspections have

been performed, the piping must be leak tested.

If the leak test requirement is a higher test pres-

sure than the maximum inlet pressure, you must

isolate the Munchkin from the gas line. In order

to do this, you must shut the gas off using fac-

tory and field-installed gas cocks. This will pre-

vent high pressure. Failure to do so may dam-

age the gas valve. In the event the gas valve is

exposed to a pressure greater than ½ PSI, 14"

water column, the gas valve must be replaced.

Never use an open flame (match, lighter, etc.) to

check gas connections.

B. GAS PIPING

1. Run the gas supply line in accordance with all

applicable codes.

2. Locate and install manual shutoff valves in

PART 8: GAS PIPING

accordance with state and local

requirements.

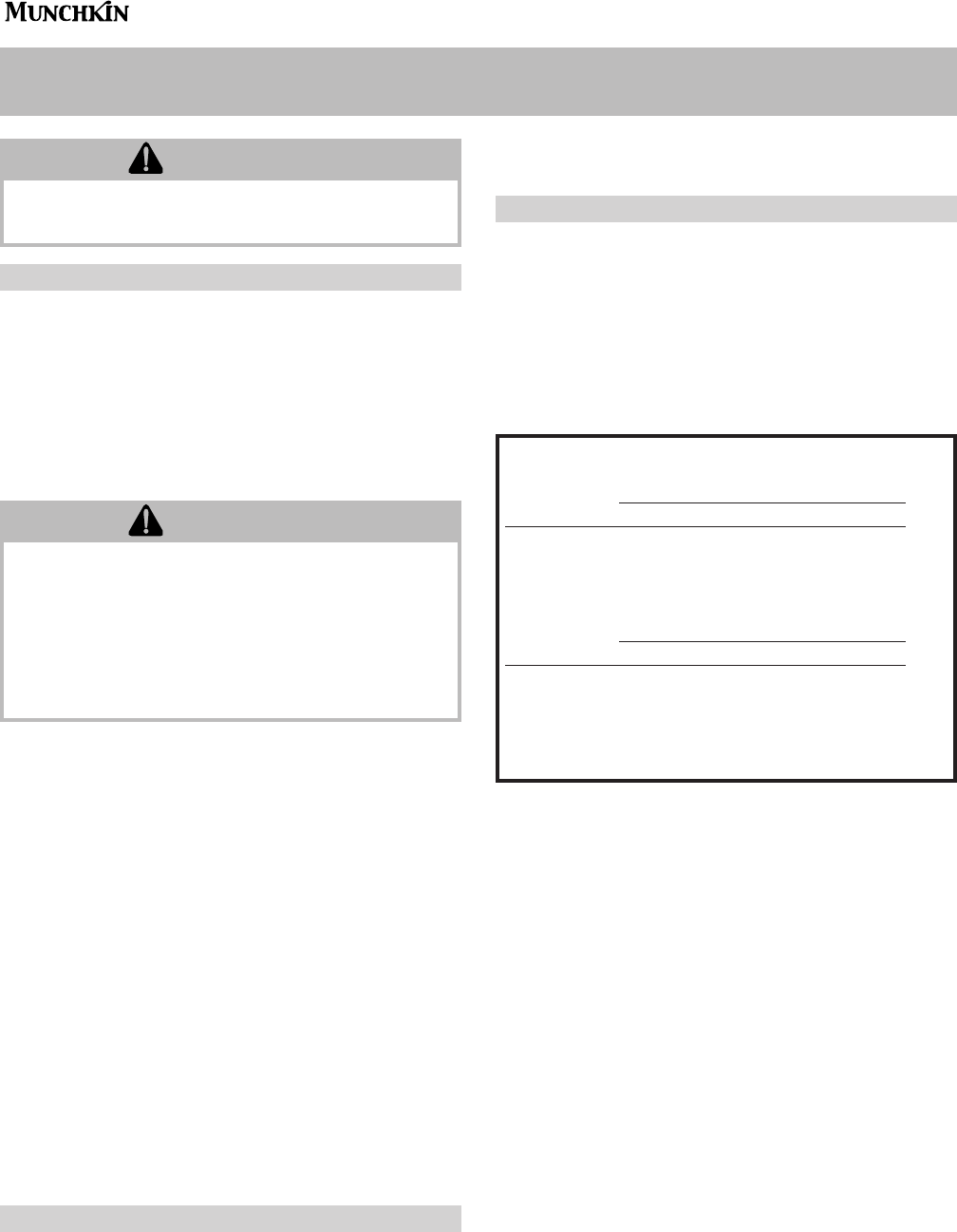

C. GAS TABLE

Refer to Table 8.1 to size the supply piping to

minimize pressure drop between meter or

regulator and unit.

Maximum Capacity of Pipe in Cubic Feet of Gas

per Hour for Gas Pressures of 0.5 psi or Less and

a Pressure Drop of 0.3 Inch water Column

Table 8-1 (Based on a 0.60 Specific Gravity Gas)

It is recommended that a soapy solution be used

to detect leaks. Bubbles will appear on the pipe to

indicate a leak is present. The gas piping must be

sized for the proper flow and length of pipe, to

avoid pressure drop. Both the gas meter and the

gas regulator must be properly sized for the total

gas load. If you experience a pressure drop greater

than 1" WC, the meter, regulator or gas line is

undersized or in need of service. You can attach a

manometer to the incoming gas drip leg, by

removing the cap and installing the manometer.

The gas pressure must remain between 3.5" and

14" during stand-by (static) mode and while in

operating (dynamic) mode. If an in-line regulator

is used, it must be a minimum of 10 feet from the

Munchkin. It is very important that the gas line is

properly purged by the gas supplier or utility.

Failure to properly purge the lines or improper

line sizing, will result in ignition failure. This

problem is especially noticeable in NEW LP

installations and also in empty tank situations. This

can also occur when a utility company shuts off

WARNING

Failure to follow all precautions could result in

fire, explosion or death!

NNoommiinnaall

IIrroonn PPiippee IInntteerrnnaall LLeennggtthh ooff PPiippee ((FFeeeett))

SSiizzee DDiiaammeetteerr

((iinncchheess)) ((iinncchheess)) 1100 2200 3300 4400 5500 6600 7700

33//44 ..882244

278 190 152 130 115 105 96

BBTTUU''SS

11 11..004499

520 350 285 245 215 195 180

PPEERR

11 11//44 11..338800

1,050 730 590 500 440 400 370

HHOOUURR

11 11//22 11..661100

1,600 1,100 890 760 670 610 560

}

xx11,,000000

8800 9900 110000 112255 115500 117755 220000

33//44 ..882244

90 84 79 72 64 59 55

BBTTUU''SS

11 11..004499

170 160 150 130 120 110 100

PPEERR

11 11//44 11..338800

350 320 305 275 250 225 210

HHOOUURR

11 11//22 11..661100

530 490 460 410 380 350 320

}

xx11,,000000

WARNING

It is very important that you are connected to

the type of gas as noted on the rating plate. "LP"

for liquefied petroleum, propane gas or, "Nat"

natural or city gas. All gas connections must be

approved by the local gas supplier, or utility in

addition to the governing authority, prior to

turning the gas supply on.