33

GAS-FIRED BOILER Boiler Manual

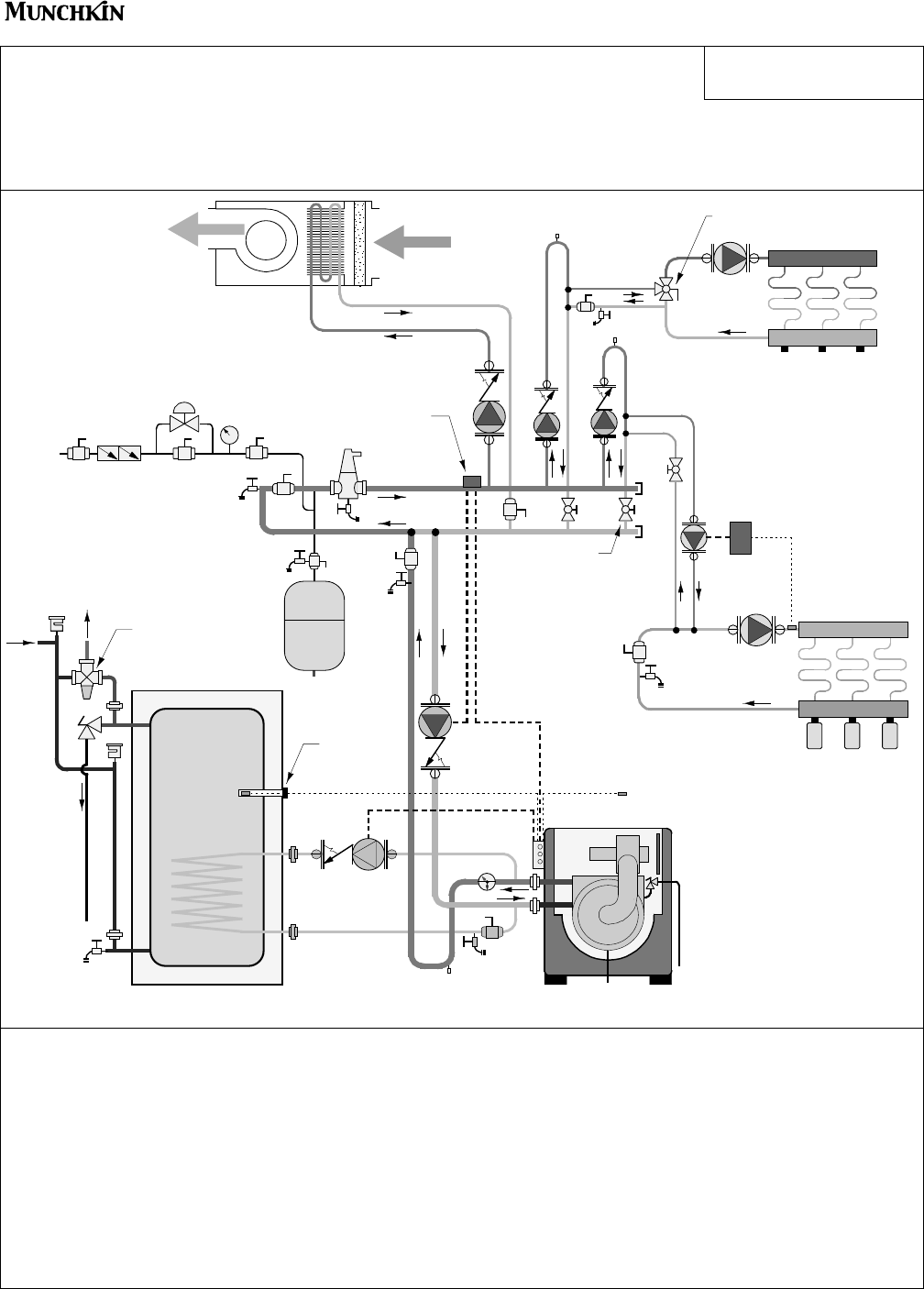

Munchkin VISION 1 system

(zoning with circulators)

Space heating mode (3 different supply temperatures)

NOTES:

1.

This drawing is meant to show system piping concept only.

Installer is responsible for all equipment & detailing required by local codes.

2.

All closely spaced tees shall be within 4 pipe diameter center to center spacing.

3. A minimum of 6 pipe diameters of straight pipe shall be installed upstream and downstream

of all closely spaced tees.

4. The minimum pipe size for connecting a Super Stor water heater is 1 inch.

5.

The minimum pipe size for connecting a Munchkin boiler shall be 1.25 inches and 2 inches for the 399M.

6. All pumps are shown with isolation flanges and integral flow check valves.

The alternative is standard flanges with full port ball valves and a separate flow check valve.

7.

The anti-scald mixing valve is recommended if the DHW temperature is set above the factory setting of 119˚F.

8. Follow all instructions for installation of injection mixing system.

9.

A purging valve may be used in lieu of the ball valve / hose bib combination shown.

10. Adjust 3-way manually-set mixing valve to yield proper supply temperature to lower temperature load.

Drawing 4F

Munchkin boiler

DHW

temp.

sensor

purge

Super Stor

indirect DHW tank

anti-scald

mixing valve

outdoor

temperature

sensor

thermal trap

(w/ drain plug)

high limit safety

air handler

(higher temp.)

vent

low temperature

manifold station

P1

P2

T/P

OFF

vent

medium

temperature

manifold station

balancing

valves

variable

speed

injection

mixing

3-way manually-set

mixing valve

purge

make-up water

purge

make-up water

cold

water

purge