26

GAS-FIRED BOILER Boiler Manual

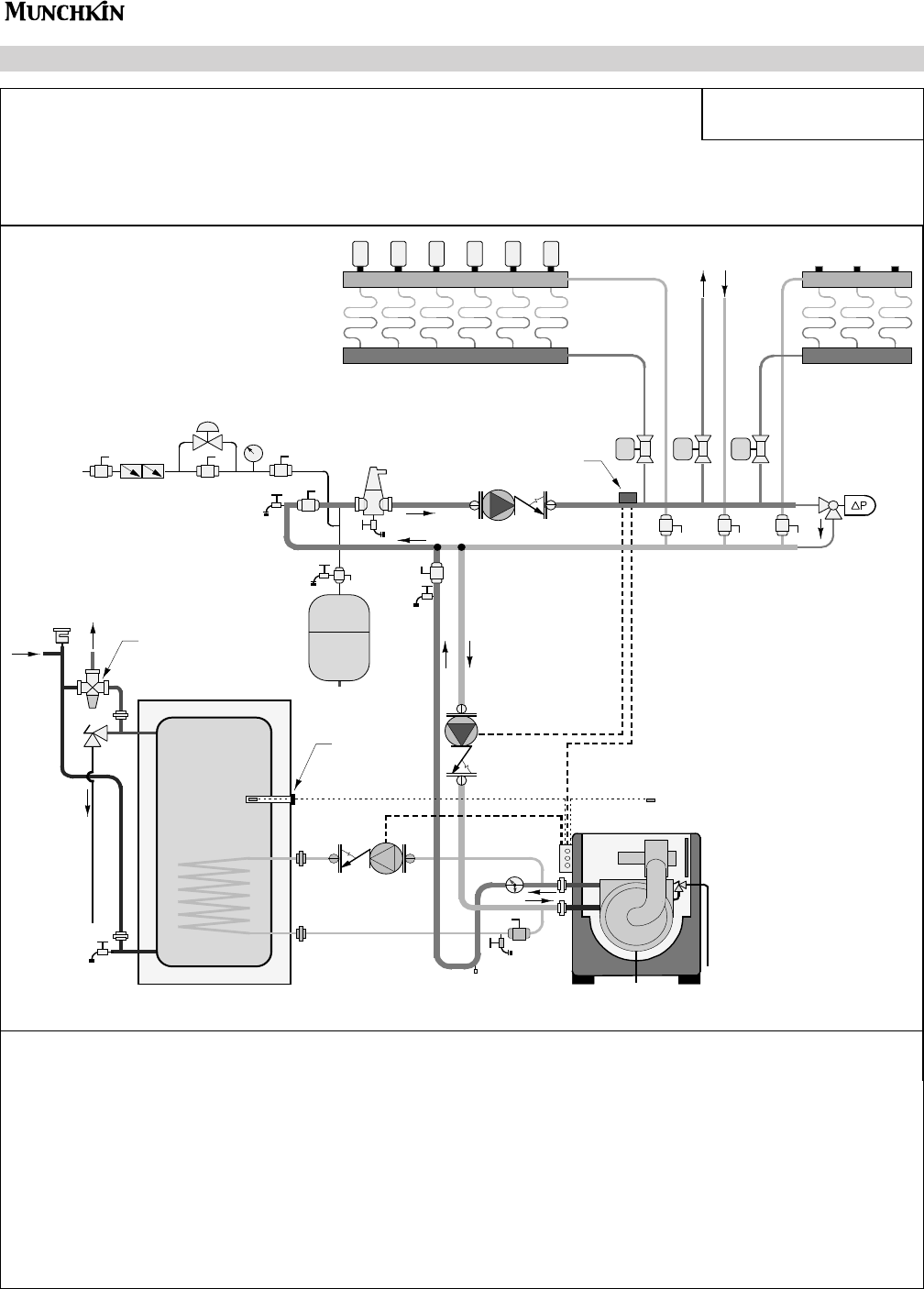

D. BOILER PIPING DETAILS WITH THE VISION I SYSTEM

Munchkin VISION 1 system

(zoning with valves)

Space heating mode

NOTES:

1.

This drawing is meant to show system piping concept only.

Installer is responsible for all equipment & detailing required by local codes.

2.

All closely spaced tees shall be within 4 pipe diameter center to center spacing.

3. A minimum of 6 pipe diameters of straight pipe shall be installed upstream and downstream

of all closely spaced tees.

4. The minimum pipe size for connecting a Super Stor water heater is 1 inch.

5.

The minimum pipe size for connecting a Munchkin boiler shall be 1.25 inches and 2 inches for the 399M.

6. All pumps are shown with isolation flanges and integral flow check valves.

The alternative is standard flanges with full port ball valves and a separate flow check valve.

7.

The anti-scald mixing valve is recommended if the DHW temperature is set above the factory setting of 119˚F.

8. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

9.

A purging valve may be used in lieu of the ball valve / hose bib combination shown.

10. Adjust differential pressure bypass valve to eliminate any flow velocity noise when zone with highest pressure

drop operates by itself.

Drawing 3A

Munchkin boiler

DHW

temperature

sensor

purge

high limit safety

zone

valves

Super Stor

indirect DHW tank

anti-scald mixing valve

outdoor

temperature

sensor

thermal trap

(w/ drain plug)

differential

pressure

bypass

valve

T/P

OFF

P1

P2

purge

make-up water

cold

water

purge