Page 30

506728−01

Pressure Switch Circuit

The defrost control incorporates two pressure switch

circuits. The high pressure switch (S4) is

factory-connected to the defrost control’s HI PS terminals

(see figure 24). The defrost control also includes a low

pressure, or loss-of-charge-pressure, switch (S87).

Switches are shown in wiring diagrams in figure 15.

During a single demand cycle, the defrost control will lock

out the unit after the fifth time that the circuit is interrupted

by any pressure switch wired to the defrost control. In

addition, the diagnostic LEDs will indicate a locked-out

pressure switch after the fifth occurrence of an open

pressure switch as listed in table 6. The unit will remain

locked out until power to the defrost control is interrupted,

then re-established or until the jumper is applied to the

TEST pins for 0.5 seconds.

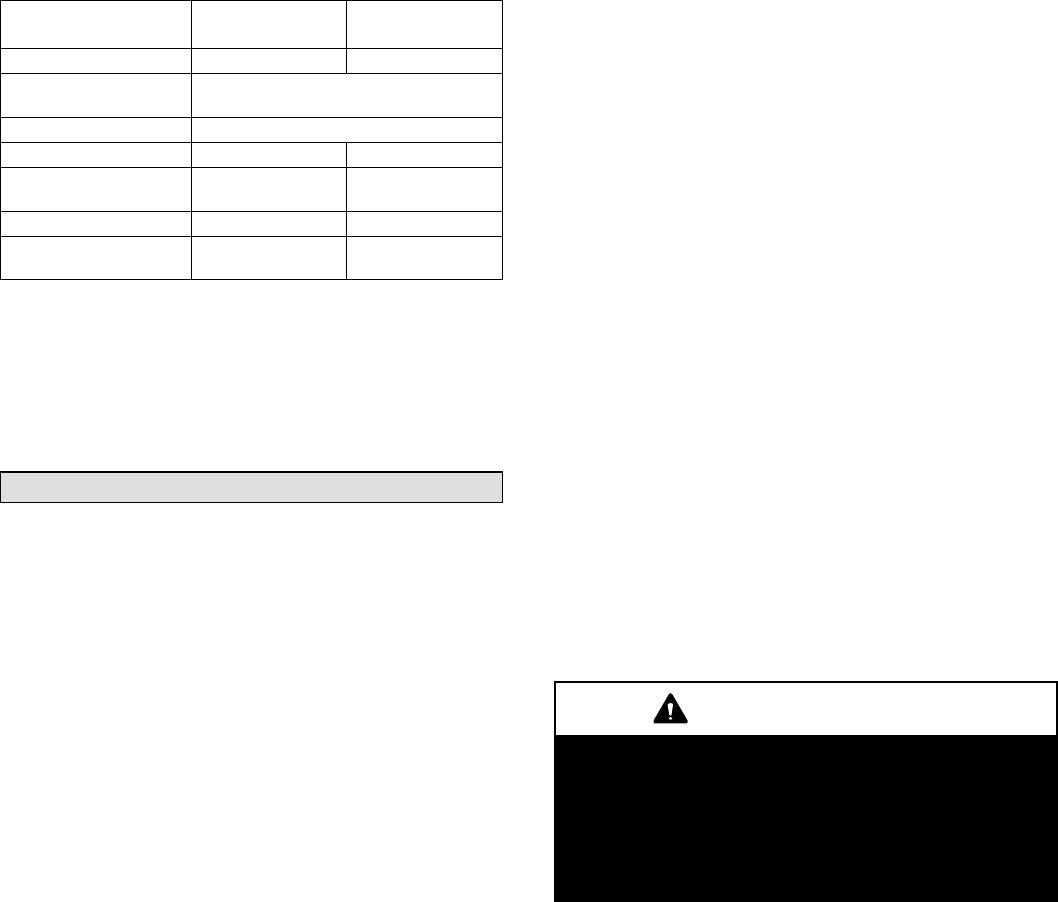

Defrost Control Diagnostic LEDs

The defrost control uses two LEDs for diagnostics. The

LEDs flash a specific sequence according to the condition.

Table 6. Defrost Control (CMC1) Diagnostic LED

Mode

Green LED

(DS2)

Red LED (DS1)

No power to control OFF OFF

Normal operation / power

to control

Simultaneous Slow FLASH

Anti-short cycle lockout Alternating Slow FLASH

Low pressure switch fault OFF Slow FLASH

Low pressure switch

lockout

OFF ON

High pressure switch fault Slow FLASH OFF

High pressure switch

lockout

ON OFF

NOTE Ċ The defrost control ignores input from the

low-pressure switch terminals as follows:

S during the TEST mode,

S during the defrost cycle,

S during the 90-second start-up period,

S and for the first 90 seconds each time the reversing

valve switches heat/cool modes.

Maintenance

DEALER

Maintenance and service must be performed by a qualified

installer or service agency. At the beginning of each

cooling season, the system should be checked as follows:

Outdoor Unit

1. Clean and inspect the outdoor coil. The coil may be

flushed with a water hose. Ensure the power is turned

off before you clean the coil.

2. Outdoor fan motor is prelubricated and sealed. No

further lubrication is needed.

3. Visually inspect connecting lines and coils for

evidence of oil leaks.

4. Check wiring for loose connections.

5. Check for correct voltage at the unit (with the unit

operating).

6. Check amp−draw outdoor fan motor.

UNIT NAMEPLATE: _________ ACTUAL: __________

NOTE Ċ If owner reports insufficient cooling, the unit

should be gauged and refrigerant charge checked.

Outdoor Coil

It may be necessary to flush the outdoor coil more

frequently if it is exposed to substances which are

corrosive or which block airflow across the coil (e.g., pet

urine, cottonwood seeds, fertilizers, fluids that may contain

high levels of corrosive chemicals such as salts)

S Outdoor Coil Ċ The outdoor coil may be flushed with

a water hose.

S Outdoor Coil (Sea Coast) Ċ Moist air in ocean

locations can carry salt, which is corrosive to most

metal. Units that are located near the ocean require

frequent inspections and maintenance. These

inspections will determine the necessary need to wash

the unit including the outdoor coil. Consult your

installing contractor for proper intervals/procedures

for your geographic area or service contract.

Indoor Unit

1. Clean or change filters.

2. Adjust blower speed for cooling. Measure the pressure

drop over the coil to determine the correct blower CFM.

Refer to the unit information service manual for pressure

drop tables and procedure.

3. Check blower drive belt for wear and proper tension.

4. Check all wiring for loose connections

5. Check for correct voltage at unit (blower operating).

6. Check amp−draw on blower motor.

UNIT NAMEPLATE: _________ ACTUAL: __________

Indoor Coil

1. Clean coil, if necessary.

2. Check connecting lines and coils for signs of oil leaks.

3. Check condensate line and clean, if necessary.

NOTE Ċ The filter and all access panels must be in place

any time the unit is in operation.

HOMEOWNER

Cleaning of the outdoor unit’s coil should be performed by

a trained service technician. Contact your dealer and set

up a schedule (preferably twice a year, but at least once a

year) to inspect and service your outdoor unit. The

following maintenance may be performed by the

homeowner.

IMPORTANT

Sprinklers and soaker hoses should not be installed

where they could cause prolonged exposure to the

outdoor unit by treated water. Prolonged exposure of the

unit to treated water (i.e., sprinkler systems, soakers,

waste water, etc.) will corrode the surface of steel and

aluminum parts and diminish performance and longevity

of the unit.