Page 23

XP14 SERIES

WARNING

Electric Shock Hazard. Can cause injury or death. Unit must be grounded in accordance with national and

local codes.

Line voltage is present at all components when unit is not in operation on units with single-pole contactors.

Disconnect all remote electric power supplies before opening access panel. Unit may have multiple power

supplies.

Unit Start−Up

IMPORTANT

If unit is equipped with a crankcase heater, it should be

energized 24 hours before unit start−up to prevent

compressor damage as a result of slugging.

IMPORTANT

During installation, service or maintenance, make sure

that copper tubing does not rub against metal edges or

other copper tubing. Care should also be taken to ensure

that tubing does not become kinked. Use wire ties to se-

cure tubing to prevent movement.

Do not secure electrical wires to tubing that carries hot

refrigerant gas. Heat from the tubing may melt the wiring

insulation causing a short circuit.

UNIT START−UP

1. Rotate fan to check for binding.

2. Inspect all factory− and field−installed wiring for loose

connections.

3. Verify that the manifold gauge set is connected as

illustrated in figure 19. Use a temperature sensor

positioned near the liquid line service port as illustrated

in figure 19 which will be required later when using the

subcooling method for optimizing the system

refrigerant charge.

4. Replace the stem caps and tighten to the value listed

in table 1.

5. Check voltage supply at the disconnect switch. The

voltage must be within the range listed on the unit’s

nameplate. If not, do not start the equipment until you

have consulted with the power company and the

voltage condition has been corrected.

6. Open both the liquid and vapor line service valves to

release the refrigerant charge contained in outdoor

unit into the system.

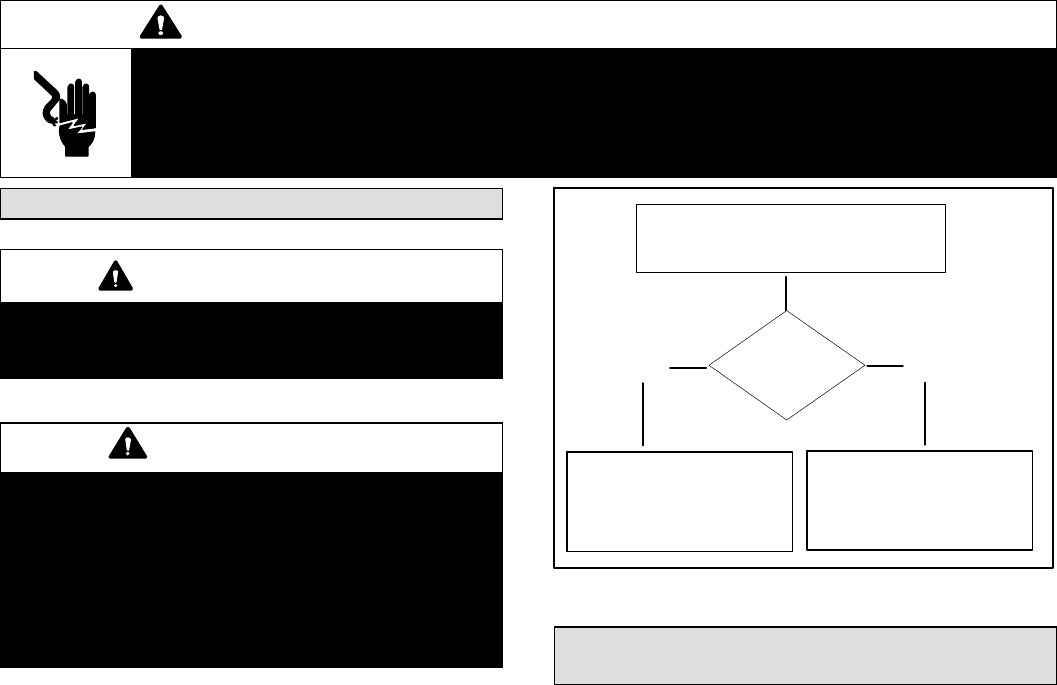

7. Use figure 18 to determine next step in system

preparation.

REFRIGERANT

PRESENT

OPEN BOTH VAPOR AND LIQUID SERVICE

VALVE STEMS TO RELEASE

REFRIGERANT FROM OUTDOOR UNIT TO

SYSTEM.

YESNO

GO TO SERVICE AND WEIGH

IN REFRIGERANT CHARGE

FOR OUTDOOR UNITS

DELIVERED VOID OF CHARGE

ON PAGE 23.

GO TO OPTIMIZING SYSTEM

REFRIGERANT CHARGE ON

PAGE 25.

Figure 18. Outdoor Unit Factory Charge

Service and Weigh In Refrigerant for

Outdoor Units Delivered Void of Charge

The following procedures are only required if it has been

determine that the new outdoor unit is void of charge. Skip

to the next section if refrigerant charge is present.

LEAK CHECK, REPAIR AND EVACUATE

If the outdoor unit is void of refrigerant, clean the system

using the procedure described below.

1. Leak check system using procedures provided on

page 17. Repair any leaks discovered during leak test.

2. Evacuate the system using procedure provided in

figure 14.

3. Use nitrogen to break the vacuum and install a new

filter drier in the system.

4. Evacuate the system again using procedure in figure

14.

CONNECT MANIFOLD GAUGE SET AND WEIGH−IN

CHARGE

After the evacuation procedure, reconnect the manifold

gauge set as illustrated in figure 19.

NOTE − Temperature sensor illustrated in figure 19 is not

required for initial system weigh in charging.

1. Close manifold gauge set valves and connect the

gauge set as exampled in figure 19.

2. Check that fan rotates freely.