Page 14

506728−01

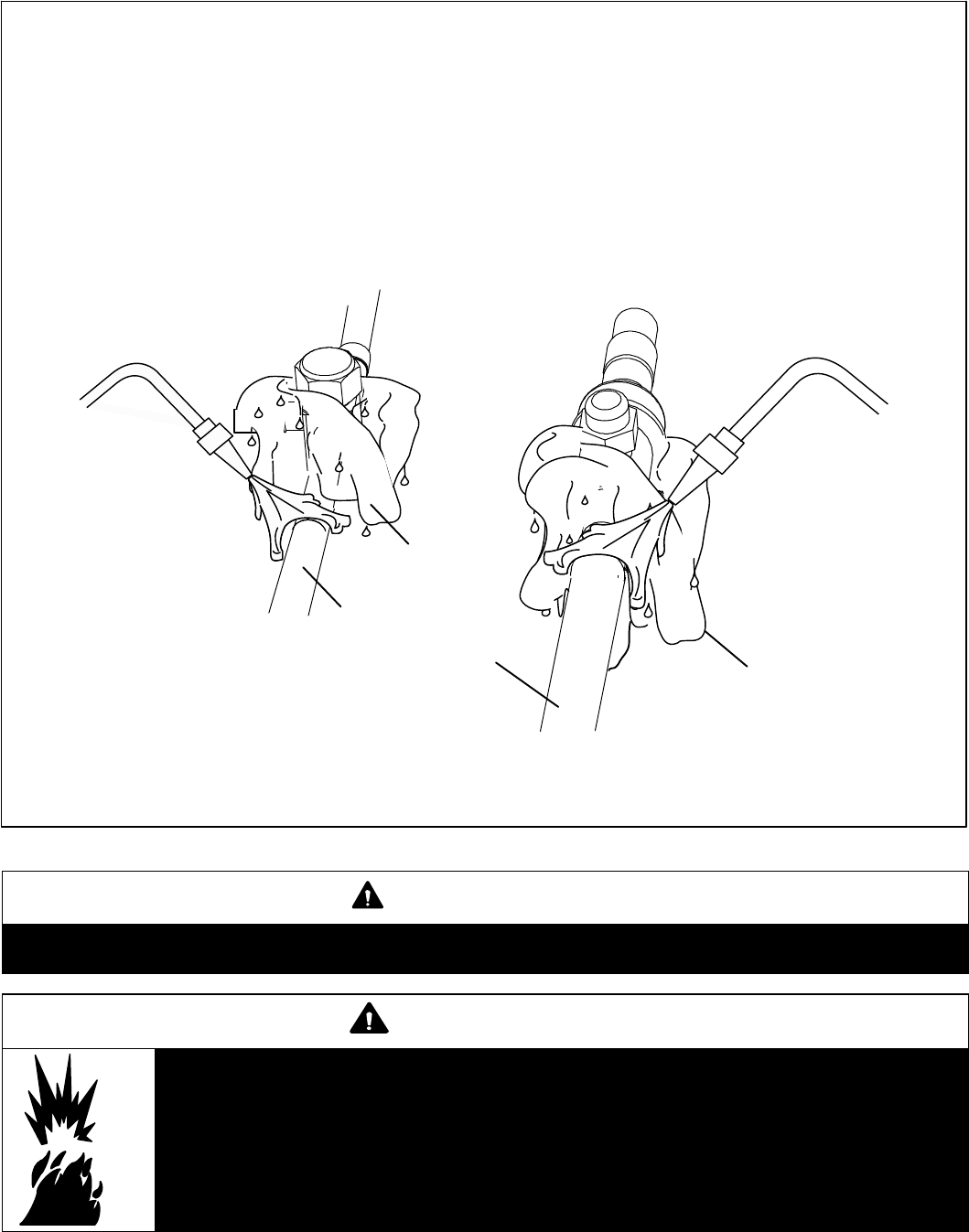

WHEN BRAZING

LINE SET TO

SERVICE VALVES,

POINT FLAME

AWAY FROM

SERVICE VALVE.

LIQUID LINE SERVICE VALVE

LIQUID LINE

BRAZE LINE SET

Wrap both service valves with water saturated cloths as illustrated here and as mentioned in step 4, before brazing to line set. Water

saturated cloths must remain water saturated throughout the brazing and cool−down process.

WATER SATURATED

CLOTH

6

SUCTION / VAPOR LINE

WATER SATURATED

CLOTH

SUCTION / VAPOR LINE

SERVICE VALVE

After all connections have been brazed, disconnect manifold gauge set from service ports. Apply additional water saturated cloths to both

service valves to cool piping. Once piping is cool, remove all water saturated cloths.

WHEN BRAZING LINE SET TO SERVICE VALVES, POINT FLAME AWAY

FROM SERVICE VALVE.

PREPARATION FOR NEXT STEP

7

WRAP SERVICE VALVES

To help protect service valve seals during brazing, wrap water saturated cloths around service valve bodies and copper tube stubs. Use

additional water saturated cloths underneath the valve body to protect the base paint.

4

FLOW NITROGEN

Flow regulated nitrogen (at 1 to 2 psig) through the refrigeration gauge set into the valve stem port connection on the liquid service valve and

out of the suction / vapor valve stem port. See steps 3A, 3B and 3C on manifold gauge set connections

5

ANGLE−TYPE SERVICE

VALVE

VAPOR LINE SERVICE VALVE

COULD BE EITHER A ANGLE−TYPE

OR BALL−TYPE VALVE.

Figure 10. Brazing Procedures (continued)

IMPORTANT

Allow braze joint to cool. Apply additional water saturated cloths to help cool brazed joint. Do not remove water saturated

cloths until piping has cooled. Temperatures above 250ºF will damage valve seals.

WARNING

FIRE, PERSONAL INJURY, OR PROPERTY DAMAGE may result if you do not wrap a water satu-

rated cloth around both liquid and suction line service valve bodies and copper tube stub while brazing

in the line set! The braze, when complete, must be quenched with water to absorb any residual heat.

Do not open service valves until refrigerant lines and indoor coil have been leak−tested and evacuated.

Refer to procedures provided in this supplement.