Page 24

506728−01

3. Inspect all factory− and field−installed wiring for loose

connections.

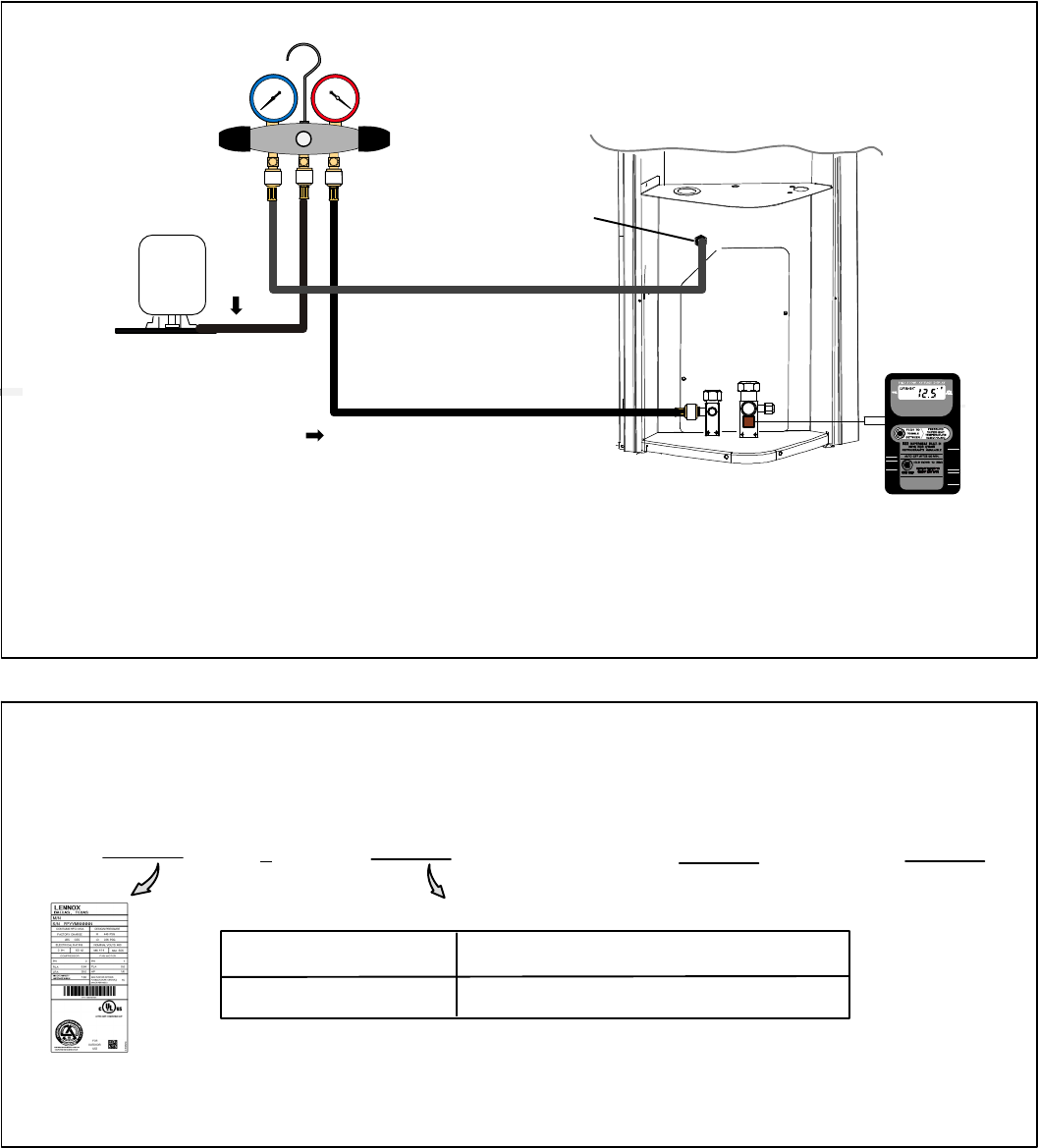

4. Open the high side manifold gauge valve and weigh in

liquid refrigerant. Use figure 20 to calculate the correct

weigh−in charge.

5. Close manifold gauge valves.

6. Monitor the system to determine the amount of

moisture remaining in the oil. It may be necessary to

replace the bi−flow filter drier several times to achieve

the required dryness level. If system dryness is not

verified, the compressor will fail in the future.

7. Continue to Optimizing System Refrigerant Charge

on page 25 to optimize the system charge using

subcooling method.

TO LIQUID

LINE SERVICE

VALVE

DIGITAL SCALE

REFRIGERANT

TANK

TEMPERATURE

SENSOR

(LIQUID LINE)

MANIFOLD GAUGE SET

A Close manifold gauge set valves and connect the center hose to a cylinder of HFC−410A. Set

for liquid phase charging.

B Connect the manifold gauge set’s low pressure side to the true suction port.

C Connect the manifold gauge set’s high pressure side to the liquid line service port.

D Position temperature sensor on liquid line near liquid line service port (use only for subcooling

method).

CHARGE IN

LIQUID PHASE

CONNECTIONS FOR OPTIMIZING SYSTEM CHARGE

GAUGE SET

A

C

D

LOW

HIGH

B

TRUE SUCTION PORT

CONNECTION

NOTE Ċ Refrigerant

tank should be turned

right−side−up to deliver

vapor during charge

optimizing procedure.

HFC−410A

NOTE Ċ For simplify the illustration,

the line set is not shown connected to

service valves.

Figure 19. Typical Gauge Set Connections for Initial Weight−in Charge or Optimizing System Charge

LIQUID LINE SET DIAMETER

OUNCES PER 5 FEET (GRAMS PER 1.5 METERS)

ADJUST FROM 15 FEET (4.6 METERS) LINE SET*

3/8" (9.5 MM)

3 OUNCE PER 5’ (85 GRAMS PER 1.5 M)

*If line length is greater than 15 feet (4.6 meters), add this amount. If line length

is less than 15 feet (4.6 meters), subtract this amount.

Refrigerant Charge per Line Set Length

NOTE Ċ The above nameplate is for illustration purposes only. Go to actual nameplate on outdoor unit for charge information.

NOTE Ċ Insulate liquid line when it is routed through areas where the surrounding ambient temperature could become higher than the temperature

of the liquid line or when pressure drop is equal to or greater than 20 psig.

CALCULATING SYSTEM CHARGE FOR OUTDOOR UNIT VOID OF CHARGE

If the system is void of refrigerant, first, locate and repair any leaks and then weigh in the refrigerant charge into the unit. To calculate the total refriger-

ant charge:

Amount specified on

nameplate

Adjust amount. for variation in line set

length listed on line set length table below.

Additional charge specified per

match indoor air handler or coil

listed in table 5.

Total Charge

+

+

=

Figure 20. Using HFC−410A Weigh In Method