5

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

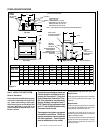

hctiPfooR

H

)teef(

21/6ottalF0.1

21/7ot21/6revO52.1

21/8ot21/7revO5.1

21/9ot21/8revO0.2

21/01ot21/9revO5.2

21/11ot21/01revO52.3

21/21ot21/11revO0.4

Figure 4

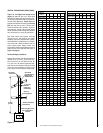

Figure 5 -

Side Elevation View

3"

(76 mm)

12"

(305 mm)

Termination Kit

Combustible Projection

greater than inches in length

Combustible Projection

2-1/2 inches or less in length

18"

(457 mm)

Ventilated

Soffit

Unventilated

Soffit

Horizontal Vent Termination Clearances

2-1/2

Termination Kit

All horizontal terminations

may be located as close

as 6” (152mm) to any

(non-combustible and

combustible) exterior

sidewall. This distance

may be decreased to

2” (51mm) for non-

combustible exterior

sidewalls only, if the

SV4.5HT-2 termination

is used.

Horizontal Vent Termination Clearances

The horizontal vent termination must have a

minimum of 3" (76 mm) clearance to any over-

head combustible projection of 2-1/2" (64 mm)

or less. See

Figure 5.

For projections exceed-

ing 2-1/2" (64 mm), see

Figure 5

. All horizontal

terminations may be located as close as 6"

(152mm) to any (non-combustible and com-

bustible) exterior sidewall. This distance may

be decreased to 2" (51mm) for non-combus-

tible exterior sidewalls only, if the SV4.5HT-2

termination is used. For additional vent location

restrictions refer to

Figure 8 on page 7

.

Terminate multiple vent terminations accord-

ing to the installation codes listed on this

page.

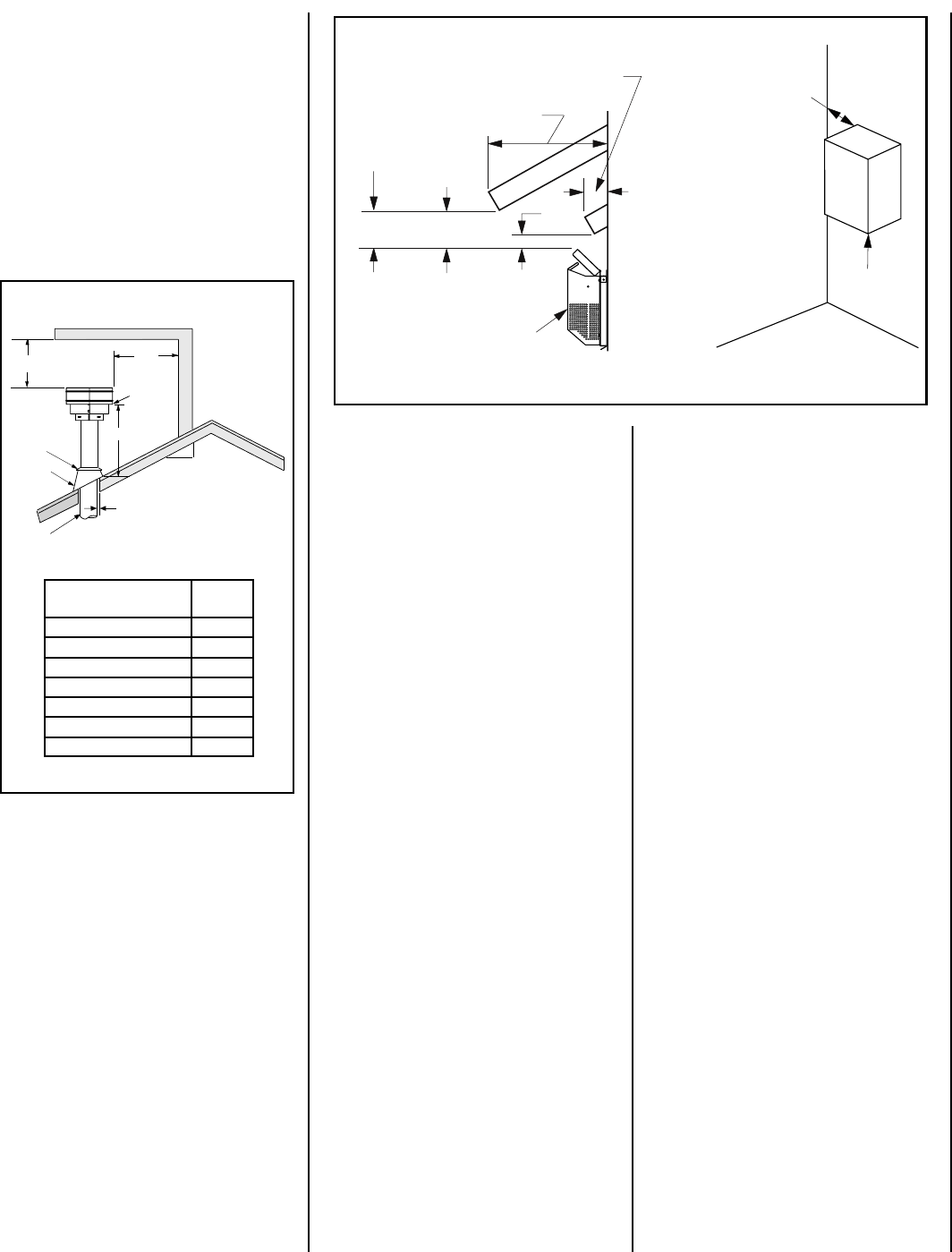

Vertical Vent Termination Clearances

VENT TERMINATION CLEARANCES

These instructions should be used as a guide-

line and do not supersede local codes in any

way. Install vent according to local codes,

these instructions, the current National Fuel

Gas Code (ANSI-Z223.1) in the USA or the

current standards of CAN/CGA-B149.1 and -

B149.2 in Canada.

Terminate single vent caps relative to building

components according to

Figure 4

.

Step 3. (page 9) Install the vent system and

exterior termination.

Step 4. (page 22) Field Wiring

a. Millivolt Appliances – Install the operating

control switch (not factory provided) and

bring in electrical service line for forced air

circulating blower (optional equipment).

b. Electronic Appliances – Field wire and

install operating control switch.

Step 5. (page 22) Install blower kit (optional

equipment).

Step 6. (page 23) Make connection to gas

supply.

Step 7. (page 24) Install the logs, decora-

tive volcanic stone and glowing embers.

Step 8. (page 24) Checkout appliance op-

eration.

Step 9. (page 24) Install glass door frame

assembly.

Step 10. (page 25) Adjust burner to ensure

proper flame appearance.

Step 11. (page 25) Install the hoods.

TYPICAL INSTALLATION SEQUENCE

The typical sequence of installation follows,

however, each installation is unique resulting in

variations to those described.

See the page numbers references in the follow-

ing steps for detailed procedures.

Step 1. (page 6) Construct the appliance

framing. Position the appliance within the

framing and secure with nailing brackets.

Step 2. (page 6) Route gas supply line to

appliance location.

12

X

Roof Pitch is X/12

2 FT

MIN.

2 FT MIN.

Lowest

Discharge

Opening

H*

*H = MINIMUM HEIGHT FROM ROOF TO

LOWEST DISCHARGE OPENING OF VENT

TERMINATION HEIGHTS FOR VENTS ABOVE

FLAT OR SLOPED ROOFS

Horizontal Overhang

Vertical

Wall

Vent

Termination

Storm Collar

Concentric

Vent Pipe

Flashing

1 inch (25.4 mm) Minimum

Clearance to Combustibles