37

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

* Standard size installed at factory

** Standard size in LP conversion kit

• Part /Cat. Number

LENNOXHEARTHPRODUCTS•MERIT

®

SERIESDIRECT-VENTCONTEMPORARYDESIGNGASFIREPLACES•MODELMLDVTCD-35•INSTALLATIONINSTRUCTIONS

Millivolt Appliances

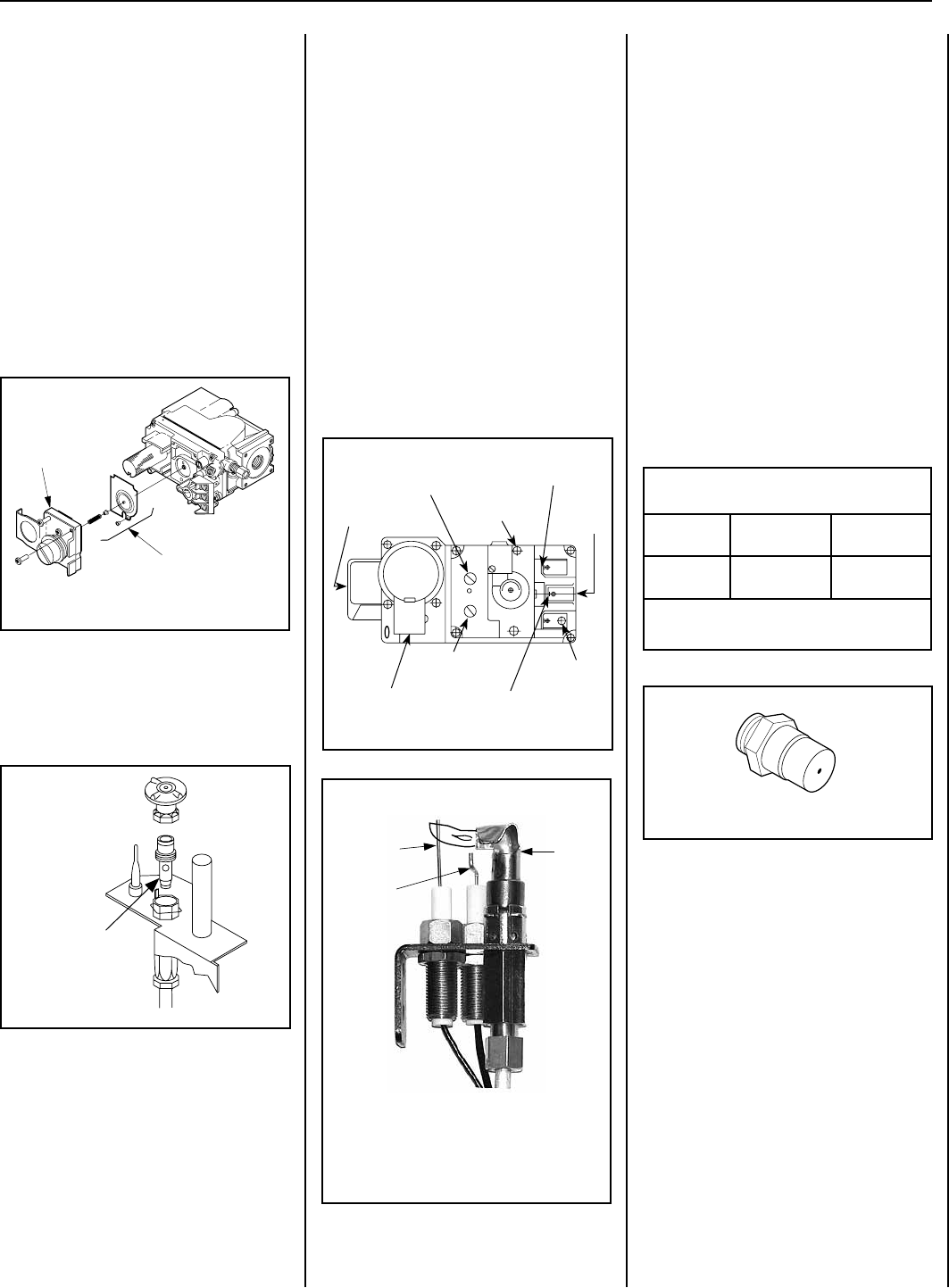

Step 5. SIT Systems - Refer to Figure 50 on

Page 37 and the instructions provided with

the kit. Using a Torx T20 (with 1/4" shank and

centerhole),toolorstandardatscrewdriver

remove and discard the three pressure regulator

mounting screws. Remove the pressure regu-

lator, spring, poppet, diaphragm and bushing.

Discard all removed components.

Ensure the rubber gasket installed on the back of

the replacement pressure regulator is properly

positioned and install the new pressure regula-

tor using the new screws supplied with the kit.

Tighten screws to 25 In. lb. torque.

Pressure

Regulator

Remove

These

Components

Pilot

Orifice

Electronic Appliances

Step 7. Dexen Electronic Valves - See Figure

52 and the instructions provided with the kit.

Remove and discard the two pressure regula-

tor mounting screws. Remove the pressure

regulator and diaphragm. Discard all removed

components. Ensure the provided diaphragm

is installed properly onto the replacement

pressure regulator and install the new pres-

sure regulator using the new screws supplied

with the kit. Tighten screws.

See Figure 53 and replace the pilot orifice as

follows: Remove pilot hood assembly to access

the phillipped pilot orifice. Remove and replace

the orifice with the one provided with the kit.

Exercise extreme care to prevent damage to

or breakage of the igniter assembly.

Step 6. See Figure 51 and remove the pilot

hood assembly to access the hexed pilot orifice.

Remove and replace the orifice with the one

provided with the kit.

Figure 50

Figure 51

Note: If the igniter is damaged, a re-

placement kit is available, order Catalog

Number 87L54.

Step 9. Reassemble the remaining components

by reversing the procedures outlined in the

preceding steps.

Step 10. Attach the conversion label provided

in the conversion kit to the rating plate on the

appliance.

Step 11. Turn on gas supply and test for gas

leaks. See Test All Connections For Gas Leaks

on Page 27.

Step 12. Attach manometer to the manifold

side pressure test fitting and verify manifold

pressure reads 3.5 inches water column (0.87

kPa) for natural gas, and 10.0 inches water

column (2.49 kPa) for propane gas.

ALWAYS TEST PRESSURES WITH THE VALVE

REGULATOR CONTROL AT THE HIGHEST

SETTING.

All Models

Step 8. (Refer to Figure 49 on Page 36 and

Figure 54)

VERIFY THE PROPER ORIFICE SIZE

BEFORE INSTALLING IT.

A. Remove the orifice from the manifold and

replace it with the one provided in the kit. See

Table 9 for orifice sizes for natural and pro-

pane models. Figure 54 illustrates the orifice.

UsepipejointcompoundorTeontapeonall

pipe fittings before installing (ensure propane

resistant compounds are used in propane ap-

plications, do not use pipe joint compounds

onarettings).

B. Retrieve the burner and slide the venturi

tube over the orifice. Set the shutter adjusting

opening as shown in Figure 49 on Page 36.

Figure 53

Figure 54

ELECTRONIC

Pilot

Hood

Sensor

Igniter

Burner Orifice Sizes

Elevation 0-4500 feet ( 0-1372 meters)

Model

Series

Nat.Gas

drill size (inches)

Propane

drill size (inches)

MLDVTCD-35

#49 (0.073")

*

21L82 •

(0.045")

**

75L10•

Table 9

Figure 52 - Dexen Electronic Gas Valve

Supply Gas

Inlet

Pressure-Tap

(Manifold)

Regulator

Mounting

Screw

Burner Stage

Terminal

Gas

Outlet

To Burner

Ground (TP)

Pilot Stage

Terminal

Pilot Gas Outlet

Pressure-Tap

(Inlet)

PILOT

OUT

VENT

LO

TH

TP

TH

TP

HI

IN

IN