UB USER INSTRUCTIONS ENGLISH 71569247 07-04

Page 28 of 32

®

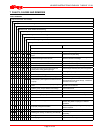

FAULT SYMPTOM

Pump overheats and seizes

⇓

⇓⇓

⇓

⇓

⇓⇓

⇓

Bearings have short life

⇓

⇓⇓

⇓

⇓

⇓⇓

⇓

Pump vibrates or is noisy

⇓

⇓⇓

⇓

⇓

⇓⇓

⇓

Mechanical seal has short life

⇓

⇓⇓

⇓

⇓

⇓⇓

⇓

Mechanical seal leaks excessively

⇓

⇓⇓

⇓

⇓

⇓⇓

⇓

Pump requires excessive power

⇓

⇓⇓

⇓

⇓

⇓⇓

⇓

Pump loses prime after starting

⇓

⇓⇓

⇓

⇓

⇓⇓

⇓

Insufficient pressure developed

⇓

⇓⇓

⇓

⇓

⇓⇓

⇓

Insufficient capacity delivered

⇓

⇓⇓

⇓

⇓

⇓⇓

⇓

Pump does not deliver liquid

⇓

⇓⇓

⇓

⇓

⇓⇓

⇓

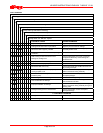

PROBABLE CAUSES POSSIBLE REMEDIES

z

zz

zz

zz

zz

zz

z

Impeller damaged or eroded. Replace impeller and check reason.

z

zz

z

Leakage under sleeve due to joint failure. Replace joint and check for damage.

z

zz

zz

zz

zz

zz

z

Mechanical seal improperly installed.

Check alignment of faces or damaged parts and

assembly method used.

z

zz

zz

zz

zz

zz

z

Incorrect type of mechanical seal for operating

conditions.

Consult Flowserve

z

zz

zz

zz

zz

zz

zz

zz

zz

zz

zz

zz

z

Shaft running off centre because of worn

bearings or misalignment.

Check misalignment and correct if necessary.

If alignment satisfactory check bearings for

excessive wear.

z

zz

zz

zz

zz

zz

zz

zz

z

Impeller out of balance resulting in vibration. Check and consult Flowserve.

z

zz

zz

zz

zz

zz

z

Abrasive solids in liquid pumped. Check and consult Flowserve.

z

zz

zz

zz

z

Mechanical seal was run dry.

Check mechanical seal condition and source of

dry running and repair.

z

zz

zz

zz

zz

zz

zz

zz

zz

zz

zz

zz

z

Internal misalignment due to improper repairs

causing impeller to rub.

Check method of assembly, possible damage or

state of cleanliness during assembly.

z

zz

zz

zz

zz

zz

z

Excessive thrust caused by a mechanical failure

inside the pump.

Check wear condition of impeller, its clearances

and liquid passages.

z

zz

zz

zz

z

Excessive grease in ball bearings. Check method of regreasing.

z

zz

zz

zz

z

Lack of lubrication for bearings.

Check hours run since last change of lubricant,

the schedule and its basis.

z

zz

zz

zz

z

Improper installation of bearings.

Check method of assembly, possible damage or

state of cleanliness during assembly and type of

bearing used.

z

zz

zz

zz

z

Damaged bearings due to contamination.

Check contamination source and replace

damaged bearings.

C. ELECTRICAL TROUBLES

z

zz

zz

zz

zz

zz

zz

zz

z

Wrong direction of rotation. Reverse 2 phases on motor terminal box.

z

zz

zz

zz

zz

zz

z

Motor running too slow. Check motor terminal box connections.