UB USER INSTRUCTIONS ENGLISH 71569247 07-04

Page 11 of 32

®

3 PUMP DESCRIPTION

3.1 Configurations

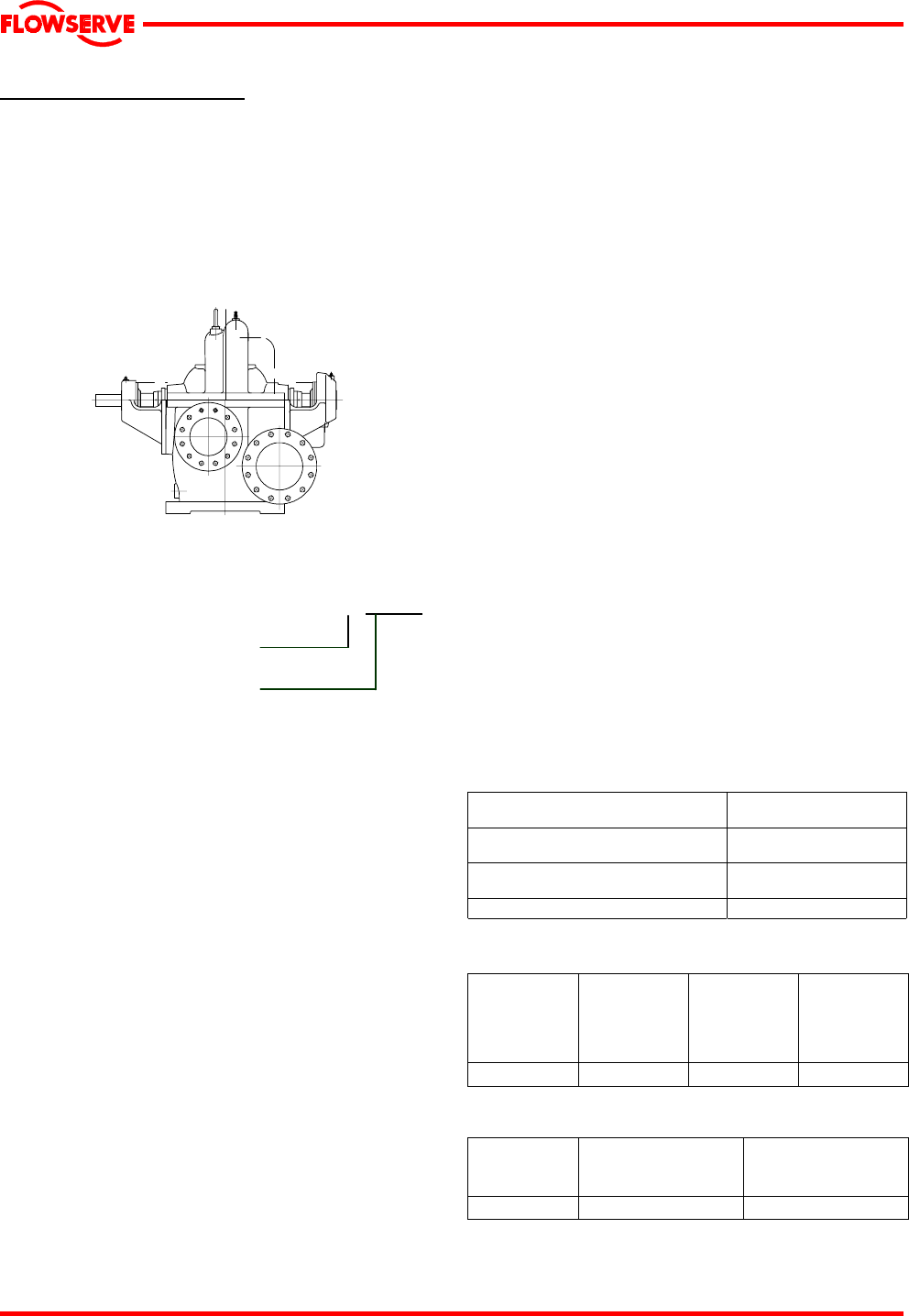

The 8-UB-1pump is a horizontal split casing two stage

volute type centrifugal pump designed for water works,

drainage, general service and circulating applications. It

can be used with motor, steam turbine and gasoline or

diesel engine drive.

It has the following horizontal configuration:

3.2 Name nomenclature

The pump size will be engraved on the nameplate

typically as below:

8-UB- 1

Nominal discharge branch size

Configuration – see 3.1 above

The typical nomenclature above is the general guide

to the UB configuration description. Identify the

actual pump size and serial number from the pump

nameplate. Check that this agrees with the

applicable certification provided.

3.3 Design of major parts

3.3.1 Pump casing

The pump has its main casing gasket axial to the

shaft allowing maintenance to the rotating element by

removing the top half casing. Suction and discharge

branches are in the bottom half and therefore remain

undisturbed.

3.3.2 Impellers

The impellers are fully shrouded and may be fitted

with optional hub rings.

3.3.3 Shaft

The large diameter stiff shaft, mounted on bearings,

has a keyed drive end.

3.3.4 Pump bearings and lubrication

Ball bearings are fitted as standard and may be either

oil or grease lubricated.

3.3.5 Bearing housing

Two grease nipples enable grease lubricated bearings

to be replenished between major service intervals.

3.3.6 Seal housing

The design enables one of a number of sealing

options to be fitted.

3.3.7 Shaft seal

The mechanical seal(s), attached to the pump shaft, seals

the pumped liquid from the environment. Gland packing

may be fitted as an option.

3.3.8 Driver

The driver is normally an electric motor. Different drive

configurations may be fitted such as internal combustion

engines, turbines, hydraulic motors etc driving via

couplings, belts, gearboxes, drive shafts etc.

3.3.9 Accessories

Accessories may be fitted when specified by the

customer.

3.4 Performance and operating limits

This product has been selected to meet the

specifications of your purchase order, see section 1.5.

The following data is included as additional information to

help with your installation. It is typical, and factors such

as temperature, materials, and seal type may influence

this data. If required, a definitive statement for your

particular application can be obtained from Flowserve.

3.4.1 Operating limits

Pumped liquid temperature limits*

- 20 to + 120 ºC

(- 4 to + 250 ºF)

Maximum ambient temperature*

- 20 to + 40 ºC

(- 4 to +104 ºF)

Maximum soft solids in suspension*

up to 3 % by volume

(refer for size limits)

Maximum pump speed

refer to the nameplate

*Subject to written agreement from Flowserve.

3.4.2 Pump and impeller data

Pump

size

Impeller

minimum

passage

size

mm (in.)

Nominal

wear

ring

diameter

mm (in.)

Mean

radial

wear ring

clearance

mm (in.) *

8-UB-1 17.5 (0.69) 266.7 (10.5) 0.19 (0.0075)

*May be up to 0.13 mm (0.005 in.) larger if casing ring and impeller

have a tendency to gaul.

Pump

size

Nominal diaphragm

bush diameter

mm (in.)

Mean radial

bush clearance

mm (in.)

8-UB-1 127 (5) 0.11 (0.0045)