6

START CAPACITOR REPLACEMENT

1. On single phase motors only, to gain access to the motor

start capacitor (376), follow steps 1 through 5 in the

“POWER CABLE REPLACEMENT” section of this

manual.

NOTICE: DISCARD STRAIN RELIEF ASSEMBLY.

IT CAN NOT BE REUSED.

FAILURE TO DRAIN CAPACITOR

OF STORED ELECTRICAL

CHARGE BEFORE SERVICE CAN

CAUSE A SEVERE SHOCK.

2. Remove the capacitor retaining screw and retaining

bracket from the motor assembly. Remove the two wires

from the capacitor. Discard the capacitor.

3. Connect the two motor wires to the new capacitor and

reassemble with the retaining bracket and retaining

screw, tightening securely.

4. Reassemble unit following steps 6 through 12 in the

“POWER CABLE REPLACEMENT” section of

this manual.

NOTICE: FOLLOW THE INSTRUCTIONS PROVIDED

IN THE “WIRING AND GROUNDING” AND

“OPERATION” SECTIONS OF THE

MANUAL AFTER UNIT DISASSEMBLY,

REASSEMBLY.

MOTOR REPLACEMENT

1. To gain access to the motor assembly, follow steps 1

through 5 in the “POWE R CABLE REPLACEMENT ”

section of this manual.

NOTICE: DISCARD STRAIN RELIEF ASSEMBLY.

IT CAN NOT BE REUSED.

2. Remove the four motor thru bolts and carefully pull

motor assembly from bearing housing. Further motor

service MUST be provided by a qualified motor repair

facility.

3. Insert the motor assembly into the bearing housing,

visually aligning the motor thru bolts through the lower

motor vent openings.

4. Install the four motor thru bolts, torquing to 35 lbs in

(4 Ν m).

5. To complete the assembly follow steps 6 through 12 in

the “POWER CABLE REPLACEMENT” section of

this manual.

NOTICE: FOLLOW THE INSTRUCTIONS PROVIDED

IN THE “WIRING AND GROUNDING” AND

“OPERATION” SECTIONS OF THE

MANUAL AFTER UNIT DISASSEMBLY,

REASSEMBLY

WARNING

Hazardous

voltage

7. Connect the power cable leads to the motor assembly as

follows:

• Single Phase Motors – Connect the BLACK wire to

motor terminal L

1

. Connect the WHITE wire to

motor terminal L

2

. Connect the GREEN wire to the

motor ground.

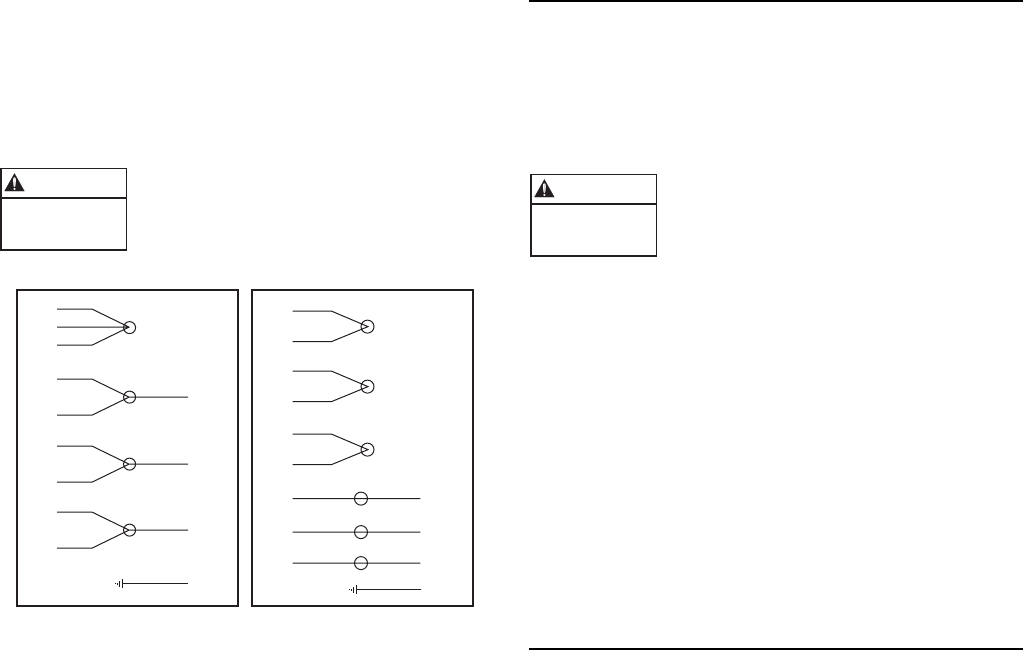

• Three Phase Motors – See Figure 1.

FAILURE TO CONNECT POWER

AND SENSOR WIRES TO

DESIGNATED WIRES CAN CAUSE

SHOCK, BURNS OR DEATH.

Figure 1

8. Wire tie the power cable to the motor assembly.

9. Slide the motor cover onto the motor assembly, while

carefully pulling the power cable out through the motor

cover hole. DO NOT damage cables. Install the four

seal housing socket head screws, torquing to 90 lbs in

(10 Ν m).

10. Install the power cable strain relief assembly torquing

the nylon bushing to 75 lbs in (8.5 Ν m) and the steel

bushing to 100 lbs in (11.3 Ν m).

11. Continue the assembly following steps 7 through 12 of

the “MECHANICAL SEAL REPLACEMENT”

section of this manual.

12. If the motor cover was replaced, it is necessary to

transfer the Goulds nameplate. Using two stainless steel

No. 2 round head metallic drive screws, install the

Goulds nameplate.

NOTICE: FOLLOW THE INSTRUCTIONS PROVIDED

IN THE “WIRING AND GROUNDING” AND

“OPERATION” SECTIONS OF THE

MANUAL AFTER UNIT DISASSEMBLY,

REASSEMBLY.

WARNING

Hazardous

voltage

1

7

2

8

3

9

6

5

4

MOTOR LEADS

L

1

L

2

L

3

G

208-230 V 3/60

7

4

MOTOR LEADS

L

1

L

2

L

3

G

460 V 3/60

8

5

9

6

1

2

3

POWER CABLE LEADS

POWER CABLE LEADS

THREE PHASE MOTOR WIRING DIAGRAM