Heatilator • Novus NDV Series • 4055-187 Rev F • 06/0840

B. Assemble Vent Sections (SLP Pipe Only)

To attach the fi rst vent component to the starting collars of

the appliance

• Attach an SLP-DVP24 adapter to the starting collar of

the appliance.

• Lock the vent components into place by sliding the pipe

section onto the collar.

• Align the seam of the pipe and seam of collar to allow

engagement. Rotate the vent component to lock into

place. Use this procedure for all vent components. See

Figure 10.5.

• Slide the gasket over the fi rst vent section and place it

fl ush to the appliance. This will prevent cold air infi ltration.

High temperature caulk may be used to hold the part in

place.

• Continue adding vent components, locking each

succeeding component into place.

• Ensure that each succeeding vent component is securely

fi tted and locked into the preceding component.

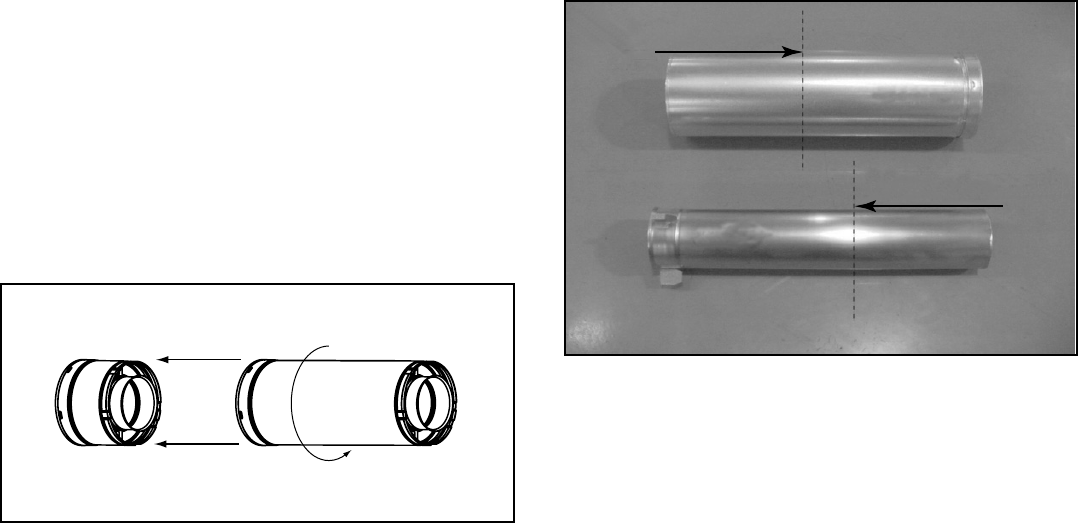

1 - Align Seams

2 - Rotate

Figure 10.5 Adding Venting Components

WARNING! Risk of Fire or Explosion! DO NOT break

silicone seals on slip sections. Use care when removing

termination cap from slip pipe. If slip section seals are bro-

ken during removal of the termination cap, vent may leak.

Commercial, Multi-family (Multi-level exceeding

two stories), or High-Rise Applications

For Installation into a commercial, multi-family (multi-level

exceeding two stories) or high-rise applications: All outer

pipe joints must be sealed with high temperature silicone,

including the slip section that connects directly to the hori-

zontal termination cap.

• Apply a bead of silicone sealant inside the female outer

pipe joint prior to joining sections. See Figure 10.1

• Only outer pipes need to be sealed. All unit collar, pipe,

slip section, elbow and cap outer fl ues shall be sealed

in this manner, unless otherwise stated.

(outer)

(inner)

Cut from this end

Cut from this end

C. Assemble MI Sections (DVP only)

WARNING! Risk of Fire or Asphyxiation! Overlap pipe

sections at least 1 1/2 in. (38 mm). Secure MI sections

with three screws which must not exceed 1/2 in. (13 mm)

in length. Pipe could separate if not properly joined.

MI (Minimum Installation) sections are non-unitized so

that they can be cut to a specifi c length.

• Cut sections to length from the non-expanded end (see

Figure 10.6). Maintain 1-1/2 in. (38 mm) overlap.

• Connect the expanded end of the MI inner fl ue with the

inner fl ue of the adjacent pipe section and secure with

three screws.

Figure 10.6 MI Sections

CAUTION! Risk of Fire! The expanded portion of the MI

inner fl ue must overlap completely with the unexpanded

end of the adjacent pipe section.

• Connect the cut end of the MI outer flue with the

expanded end of the outer fl ue of the adjacent pipe

section and secure with three screws.

• It is acceptable to use screws no longer than 1/2 in. (13

mm) to hold outer pipe sections together. If predrilling

holes, DO NOT penetrate inner pipe.

• Continue adding pipe sections as necessary following

instructions in “Assemble Pipe Sections.”

ÎÎ