8

PF100

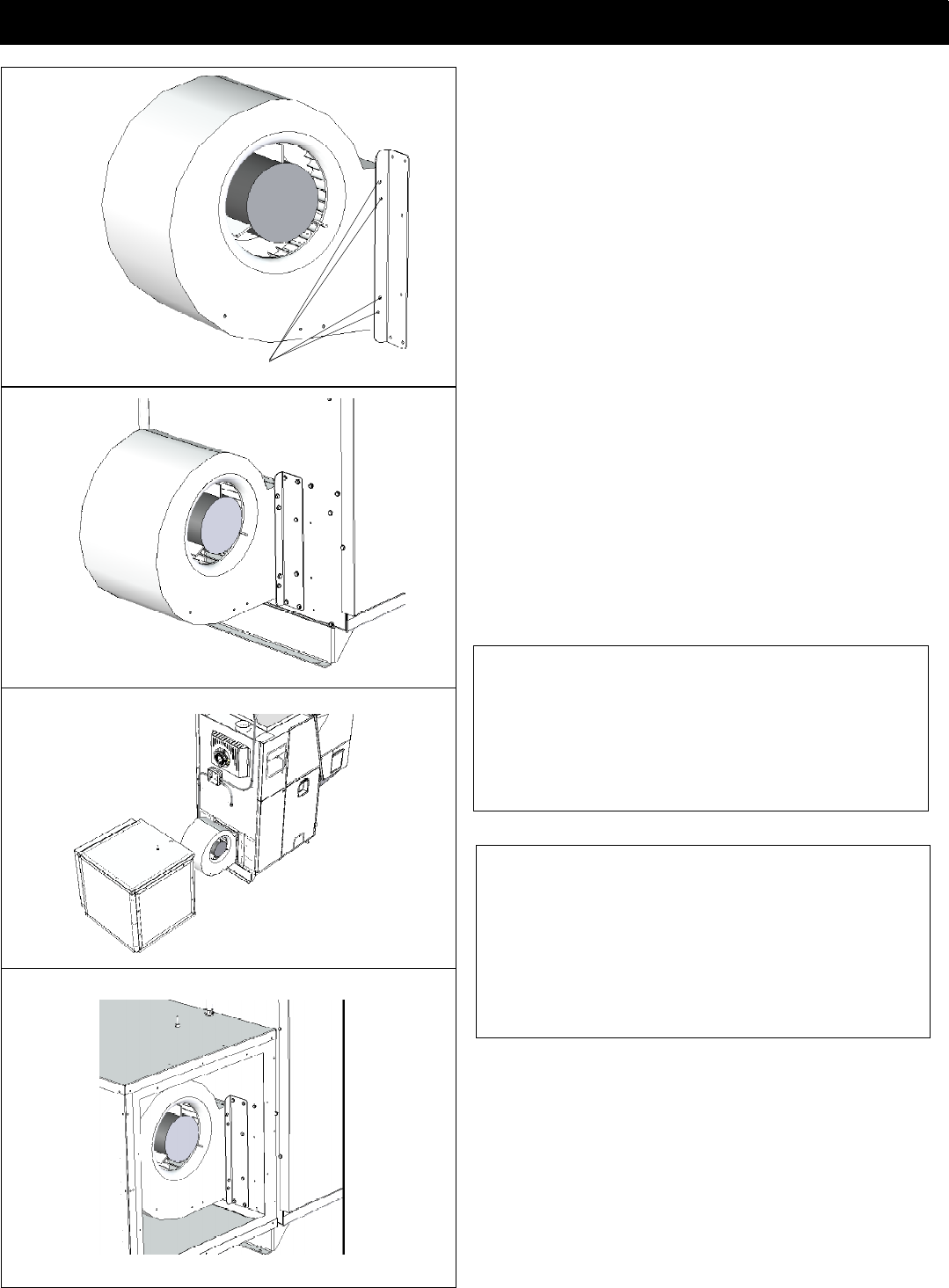

Mounting Screws

Fig. 11

Fig. 13

Fig. 14

Fig. 12

Blower Assembly

Install the blower mounting brackets on the blower

as shown in Fig. 11.

1. Install ( 4) Tek screws on each side where shown

in Fig. 11. Start with the two center screws.

NOTE: There are two small holes in the discharge

end of the blower that match the two center holes on the

small angle of the blower bracket. The two (2) outer

holes are drilled by theTek screws.

2. Mount blower with brackets installed on the

furnace as shown in Fig. 12. Each side will require 6

Tek screws.

NOTE: The furnace blower opening is made large

enough for the use of a 1500 or 2000 CFM blower.

The blower mounting brackets will fit either blower. The

inner hole pattern is for the 1000 CFM blower and the

outer pattern is for the 1500 or 2000 CFM blower.

NOTE: These Blower Motors are not designed to

be operated without any positive static back

pressure. OPERATION WITHOUT SUPPLY

DUCTWORK OR IN FREE AIR WILL CAUSE

MOTOR OVERLOAD AND PREMATURE

FAILURE.

3. Mount the filter box on the furnace with ( 8 )

10 x 3/4 Tek screws, 3 on each side. Visually locate

these holes so you are familiar with their location on the

filter box and the furnace. Access to the mounting holes

can be gained through the blower access panel cover

and the filter opening. See Fig. 14.

Note: Two pieces of 2x4 stacked laying flat on

the floor 12 inches from the blower opening will support

the filter box during installation.

CAUTION: Regardless of the supply air duct size

installed, the Distribution Blower Motor MUST be

checked for running Amperage. Check the motor name

plate for the full load AMPS. If the amperage is running

higher than that listed, a supply air restricting damper

may be required to increase the supply plenum positive

static pressure.

Assembly