A

regulator is required on the propane tanks.

Check inlet supply pressure at the unit and Piping must be gas tight and a non-hardening

upstream of the gas control. Make sure pipe compound resistant to the actions of LP

the inlet supply pressure for natural gas is gas must be used.

6-7in. w.c. (1.2-1.7kPa) and 12-14in. w.c.

(3.0-3.5kPa) for LPG.

Supply piping, including union and external

shutoff valve, are not provided.

Purging air from gas lines and piping

must be done in accordance to the instr-

GAS PRESSURE

S

uctions outlined in ANSI Z223.1-latest Table 3 Pressures

edition CAN/CGA-B149 codes. MAN.

PRESS.

Never

exceed 14in. w.c. (3.5kPa) gas

IN. W.C.

pressure to the controls on the unit (kPa)

heater.

NAT. 3.5 (.87) 14.0 (3.5) 6.0 (1.2)

LPG 10.0 (2.5) 14.0 (3.5) 11.0 (2.7)

The gas line should be as short as possible, be

of adequate size to prevent undue pressure drop The manifold pressure may be measured by

and never be smaller than the connection removin

g

the pipe plu

g

on the downstream

provided at the heater. Consult the local utility for side of the gas control and connecting a water

complete details on special requirements in manometer.

sizing gas piping. See Table 5 on page 12.

Only a small variation in gas input may be

Connect the gas pipe to the heatersft. control, made by adjusting the regulator. In no case

providing a ground joint union to the controls and should the final manifold pressure var

y

b

y

more

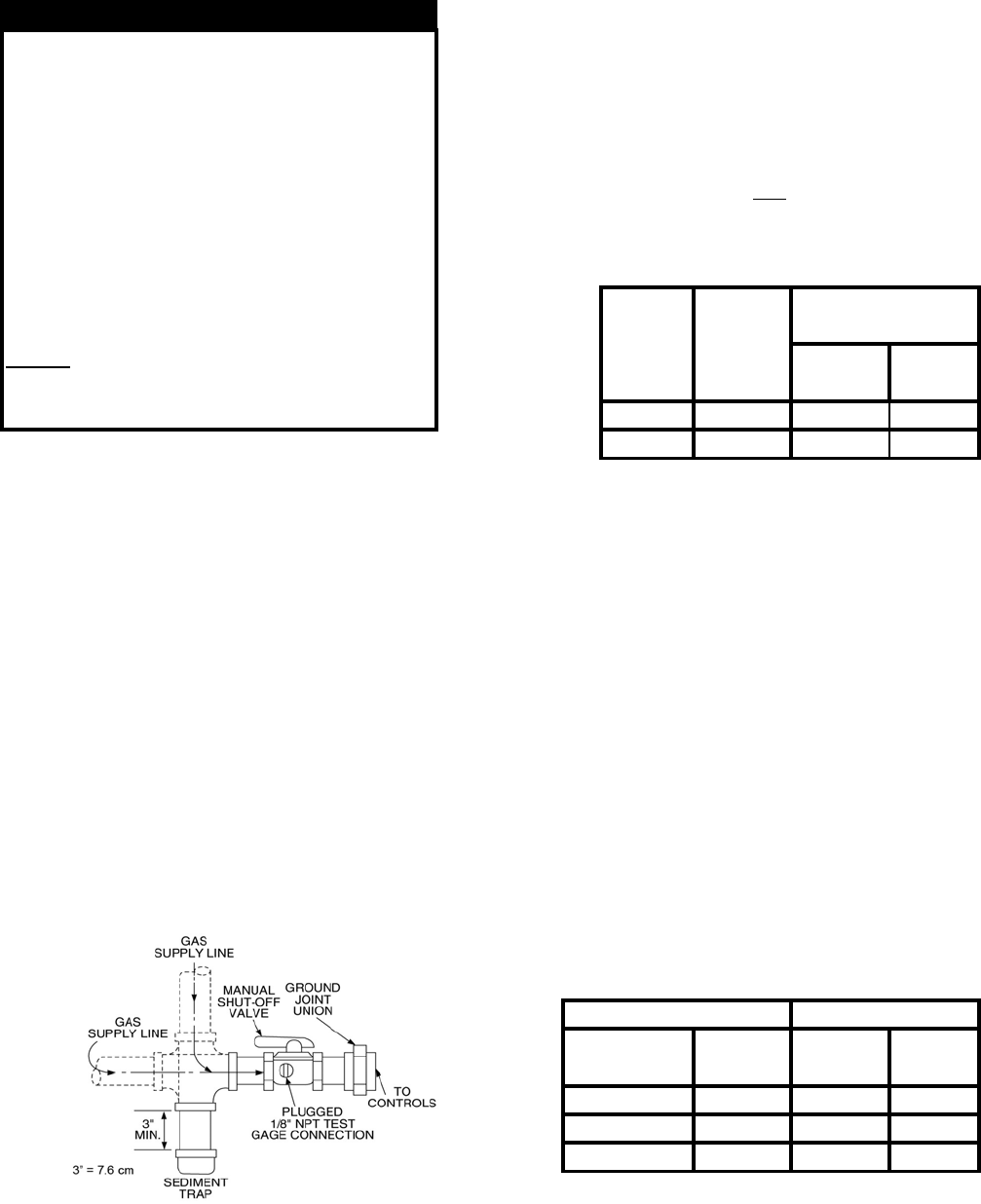

manifold. Provide a drip le

g

. See fi

g

ure 7. An than 0.3" w.c. (.1kPa) from the above specified

additional manual shutoff valve with a 1/8in. (.3cm) pressures shown in Table 3. Where the

N.P.T. plugged tapping accessible for test gage supplied gas pressure has a greater specific

connection shall be installed external to the unit. gravity use the multiplying factors shown in

Table 4.

FIGURE 7 PIPING TO CONTROLS

Table 4 SPECIFIC GRAVITY

CONVERSION FACTORS

Multiply factors to be used with Table 4 when

the specific gravity of gas is other than 0.60.

Natural Gas LP (Propane) Gas

Specific Specific

Gravity Factor Gravity Factor

0.55 1.04 1.50 0.633

0.60 1.00 1.53 0.626

0.65 0.962 1.60 0.612

Make sure the piping is pitched upward Follow these two (2) methods for input

towards the unit at least 1/4in. (.6cm) per 15ft. adjustment:

(4.6m) of horizontal run.

Method A - Meter Timing

To check a heaters input rate, observe the gas

CAUTION

GAS

SUPPLY PRESS.

INCHES W.C. (kPa)

MAX. MIN.

11