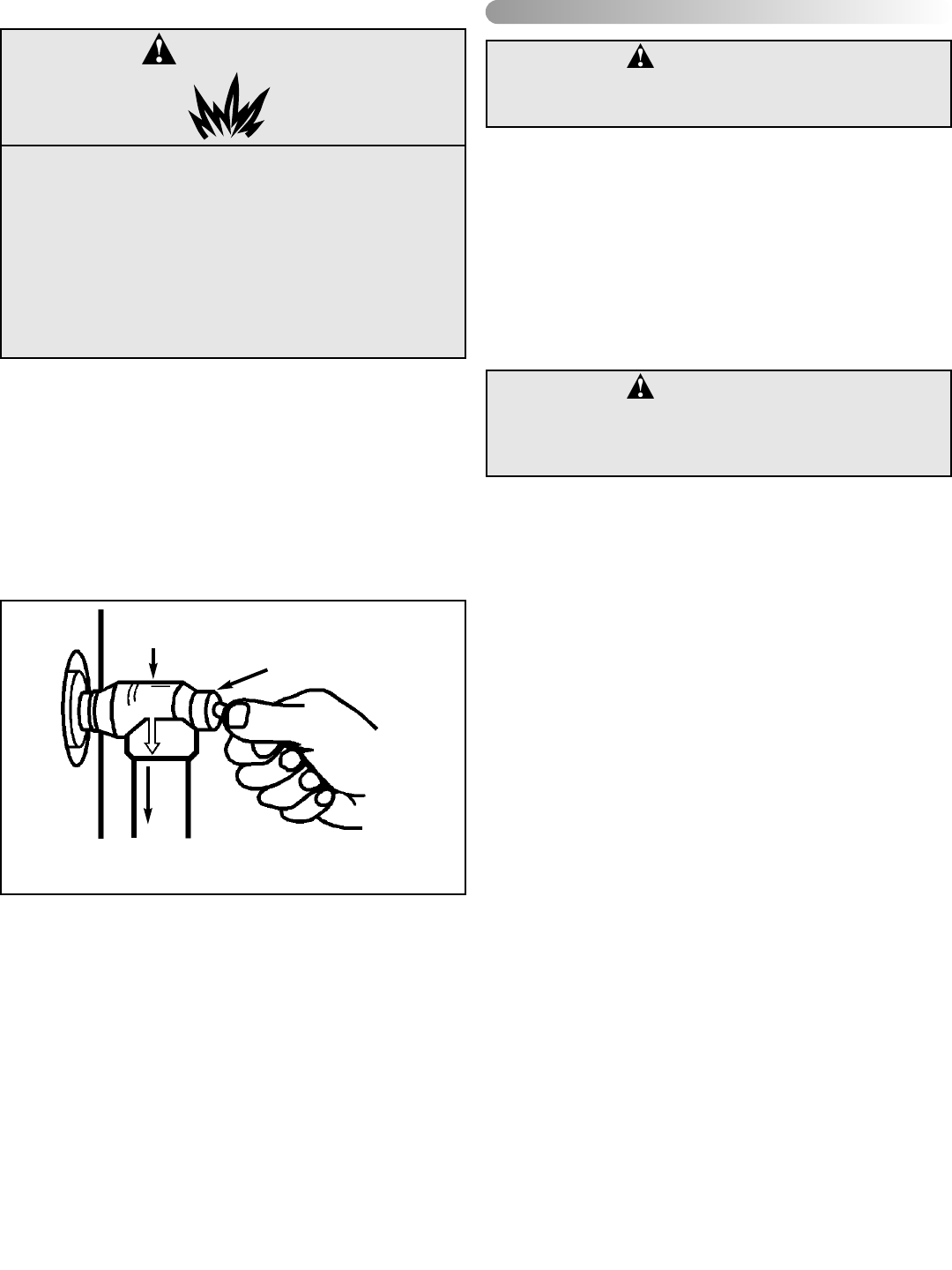

Temperature and Pressure Relief Valve

Manually operate the temperature and pressure relief valve

at least once a year to make sure it is working properly (see

Figure 27). To prevent water damage, the valve must be

properly connected to a discharge line that terminates at an

adequate drain. Standing clear of the outlet (discharged

water may be hot), slowly lift and release the lever handle

on the temperature and pressure relief valve to allow the

valve to operate freely and return to its closed position. If the

valve fails to completely reset and continues to release

water, immediately shut off the manual gas valve and the

cold water inlet valve and call a qualified service technician.

Replacement Parts

Replacement parts may be ordered through your plumber or

the local distributor. When ordering replacement parts,

always have the following information ready:

1. model, serial and product number

2. type of gas

3. item number

4. parts description

See “Replacement Parts Illustration” for a list of available

repair parts.

This section serves as a guide for the installation and use of

“Combo” heating systems utilizing a domestic water heater

that has been specifically approved for such use. It is writ-

ten for those knowledgeable in the required trades and pro-

fessionals involved in the design and installation of Combo

Heating Systems.

It is the responsibility of the installer/designer to follow

all applicable codes to ensure the effectiveness and

safety of the installation.

Read Before Proceeding

The following requirements must be met for the installation

of Combo Heating Systems:

1. All components used for the distribution of water in the

heating loop must be suitable for potable water. These

include all piping, fittings, solder and fluxes, pumps for

circulation of water, valves, etc.

2. The water heater must not be connected to a hydronic

heating system that has been used previously.

3. No boiler treatment chemicals of any kind shall be intro-

duced into the system.

4. The Combo System components must be selected and

sized to meet and maintain the total calculated

demands for both domestic service hot water and space

heating requirement. The sizing and installation must be

performed in accordance with good engineering prac-

tice such as “ASHRAE Handbooks”, HRAI,

“Hydronics Institute Manuals”, CSA B149.1, NFPA

54, ANSI Z223.1, CSA F280, National/Provincial

Building Codes, CSA C22.1, ANSI/NFPA 70, CSA

B51 and/or codes having jurisdiction.

5. The air handler (fan coil) and/or the circulating pump in

a baseboard hydronic loop will require a dedicated

120V circuit. This must be provided and identified for

this purpose.

6. All piping between the water heater and the air handler

or hydronic baseboard loop must be adequately insulat-

ed to reduce heat loss.

7. If the local jurisdiction requires a back-flow preventer in

the cold water line, an expansion tank of adequate size

must be installed.

8. “Combo” Heating Systems require higher water temper-

atures than other applications. When the system is

used to supply water for Combo Heating applications, a

means, such as mixing valve, must be installed to tem-

per the water in order to reduce scald hazard potential

(see Figures 28 & 29).

VII) COMBO HEATING

WARNING:

Keep the area around the heater clear and

unobstructed.

Temperature and Pressure

Relief Valve

Manual Relief Valve

Discharge line to drain

Figure 27 T&P Valve Test

WARNING

Explosion Hazard

• If the temperature and pressure relief

valve is dripping or leaking, have a

licensed plumber repair it.

• Do not plug valve.

• Do not remove valve.

• Failure to follow these instructions can

result in death or an explosion.

CAUTION:

Keep safety your first priority. Take all pre-

cautions to avoid creating a fire, health or

safety hazard.

– 25 –