2. Must provide proper support for all pipes protruding

through roof.

3. The vertical roof terminations should be sealed with a

plumbing roof boot or equivalent flashing.

The specifications are displayed in Figure 11.

Vent Pipe Installation

Refer to Table 2 for maximum and minimum vent length.

Plan the vent system layout so that proper clearances are

maintained from plumbing and wiring. Vent pipes serving

power vented appliances are classified by building codes as

"vent connectors". Required clearances from combustible

materials must be provided in accordance with information

in this manual under "Location Of Heater" and with the lat-

est edition of "Natural Gas and Propane Installation

Code" CAN/CSA-B149.1 (Canada), or "National Fuel Gas

Code" ANSI Z223.1 (NFPA 54) (U.S.A.) and local codes.

1. Construct and route vent pipe connections to the water

heater.

2. Ensure all vent components fit properly.

3. When all the components fit properly apply solvent

cement to join them permanently.

4. Proceed to attach the venting system to the rubber cou-

pling of the water heater (see Figures 15 & 16).

Important: The following guidelines, and those shown in

Figures 12 & 13 are good, recommended practice for vent-

ing installations. Applicable local codes supersede this set

of venting guidelines:

• Venting should be as direct as possible with a minimum

number of pipe fittings.

• Vent diameter must not be reduced unless specifically

noted in the installation instructions.

• Support all horizontal pipe runs every 1.2m (4 ft.) and all

vertical pipe runs every 1.5m (5 ft.) or according to local

codes.

• Vents run through unconditioned spaces where below

freezing temperatures are expected, are not recom-

mended.

• If a run through an unconditioned space is unavoidable,

the pipe must be insulated to reduce condensation.

• The length and number of the 90° elbows must be kept

to a minimum.

• No back-to-back 90° elbows should be used.

• If re-direction of flue gases is required, use 45° elbows

where possible, to minimize the number of 90° elbows

used.

• Do not use short radius elbows.

• No Street elbows (female-male) should be used.

• Pipes must be cut at a 90° angle.

• Deburr the outside and inside of the cut pipe so that sol-

vent cement is not pushed away by sharp edges.

• Dry fit all pipes and fittings before joining the parts with

solvent cement.

• Parts must fit well and not put stress on any sections.

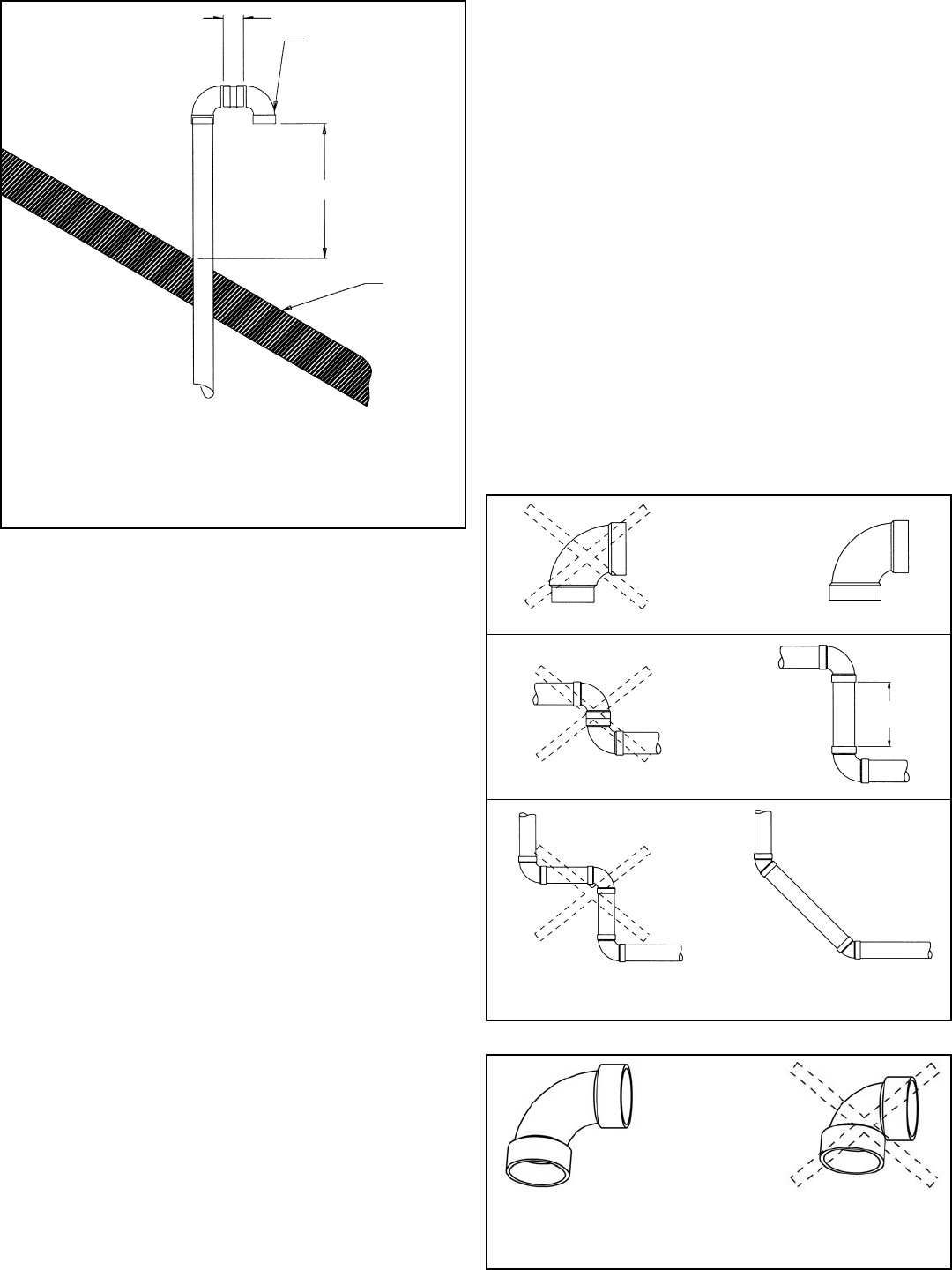

TERMINATION MAY BE

90° ELBOW OR A “T”

ELBOW

76mm (3 in.)

MIN. LENGTH

ROOF

LINE

450mm (18 in.)

Figure 11 Vertical Venting

A VENT USED IN A SPECIAL VENTING SYSTEM WITH POSITIVE VENT PRES-

SURE AND PASSING THROUGH AROOF SHALL EXTEND AT LEAST450mm (18

in.) ABOVE THE HIGHEST POINT WHERE IT PASSES THROUGH THE ROOF

SURFACE AND ANY OTHER OBSTRUCTION WITHIN A HORIZONTAL DIS-

TANCE OF 450mm (18 in.). A VERTICAL VENTING SYSTEM MUST BE SUP-

PORTED EVERY 2.4m (8 ft.).

PREFERRED PRACTICE

Figure 12 Venting Examples

150mm

(6 in.) min.

STREET ELBOW NORMAL ELBOW

BACK TO BACK ELBOWS

Figure 13 Correct Pipe Fittings

90° LONG SWEEP ELBOW

EQUIVALENT TO 1.5m (5 ft.)

OF STRAIGHT PIPE

90° SHORT SWEEP ELBOW

EQUIVALENT TO 2.4m (8 ft.)

OF STRAIGHT PIPE

– 13 –