38

ATMOSPHERE

PORT

DIRECTION

FLOW

PS

CONNECTION

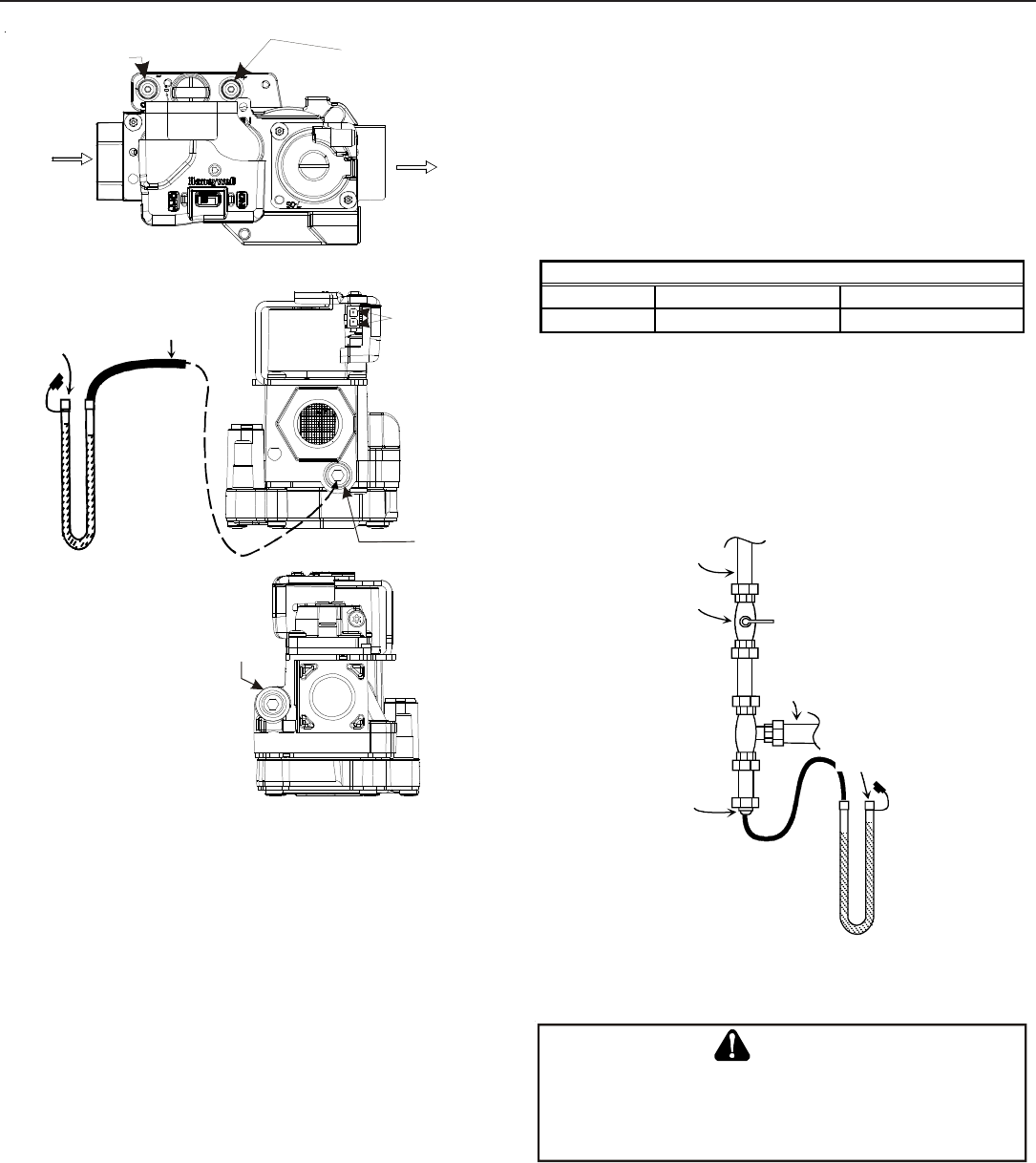

Honeywell Model VR9205R

Outlet

Pressure

Tap

1/8 NPT

Inlet

Pressure

Tap

1/8 NPT

2-PIN

POWER

CONNECTOR

i

M

a

n

o

m

e

t

e

r

M

a

n

o

m

e

t

e

r

H

o

s

e

O

p

e

n

t

o

A

t

m

o

s

p

h

e

r

e

Honeywell Model VR9205R Connected to Manometer

1. Turn OFF gas to furnace at the manual gas shutoff valve

external to the furnace.

2. Connect a calibrated water manometer (or appropriate gas

pressure gauge) at either the gas valve inlet pressure boss

or the gas piping drip leg. See Honeywell VR9205R gas

valve figure for location of inlet pressure boss.

NOTE: If measuring gas pressure at the drip leg or Honeywell

VR9205R gas valve, a field-supplied hose barb fitting must be

installed prior to making the hose connection.

3. Turn ON the gas supply and operate the furnace and all

other gas consuming appliances on the same gas

supply line.

Field Test Mode is intended to help a service person

troubleshoot and check out an installed appliance.

To enter Field Test Mode the Fault Recall Push-Button

must be pressed twice within a 5 second period at any

time during a heating cycle, at which time the display

will show “Ft”. While the display is showing “Ft”,

pressing and holding the Fault Recall Push-Button for

3 seconds will enable the field test mode and override

the normal firing rate sequence at a rate of 100% for 5

minutes or until the end of the call for heat. The display

will show the normal “Hi” while the control is firing at

100%. If the Fault Recall Push-Button has not been

pressed within 5 seconds of displaying “Ft” the display

will revert back to normal.

4. Measure furnace gas supply pressure with burners firing.

Supply pressure must be within the range specified in the

Inlet Gas Supply Pressure table.

Natural Gas

Minimum: 5.0" w.c. Maximum:10.0" w.c.

Propane Gas

Minimum: 11.0" w.c. Maximum:13.0" w.c.

Inlet Gas Supply Pressure

If supply pressure differs from table, make the necessary adjust-

ments to pressure regulator, gas piping size, etc., and/or consult

with local gas utility.

5. Turn OFF gas to furnace at the manual shutoff valve and

disconnect manometer. Reinstall plug before turning on

gas to furnace.

6. Turn OFF any unnecessary gas appliances stated in step

3.

Gas Line

Gas

Shutoff

Valve

Gas Line

To Furnace

Drip Leg Cap

With Fitting

Manometer Hose

Manometer

Open To

Atmosphere

Measuring Inlet Gas Pressure (Alt. Method)

GAS MANIFOLD P RESSURE MEASUREMENT

T

O

PREVEN T

UNRELIABLE

OPE RATION

OR

EQUIPMENT

DAMAGE

,

THE

GAS

MANIFOLD

PRESSURE

MUST

BE

AS

SPECIFIED

ON

THE

UNIT

RATING

PLATE

.G

AS

VALVE

IS

FACTORY

SET

AND

DOES

NOT

REQ UIRE

ANY

F

IELD

ADJUSTMENT

.D

O

NOT

ATTEMP T

TO

ADJUST

VALVE

.

CAUTION

The manifold pressure must be measured with the burners operat-

ing. To measure the manifold pressure, use the following proce-

dure.

1. Turn OFF gas to furnace at the manual gas shutoff valve

external to the furnace.

2. Turn off all electrical power to the system.