10

221834B

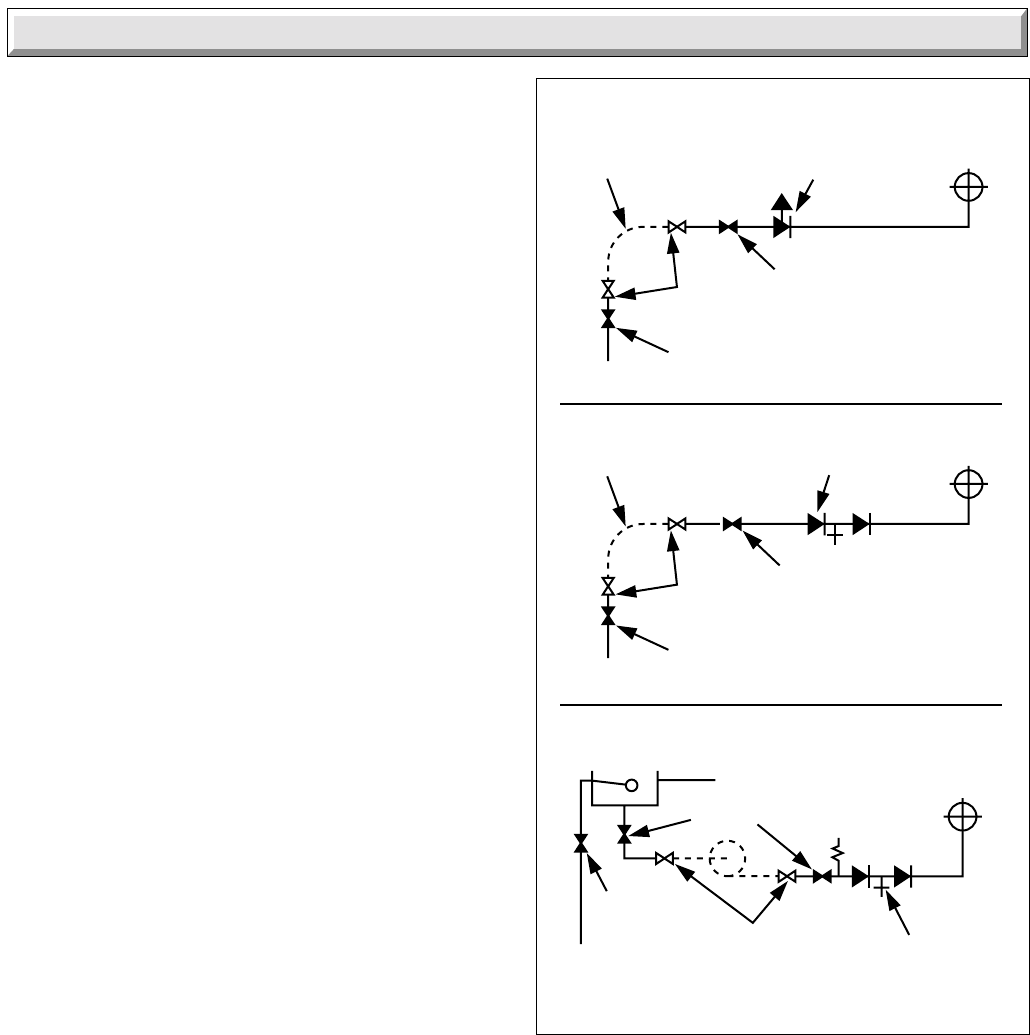

Diagram 2.5

METHOD 1

METHOD 2

METHOD 3

SUPPLY STOP

VALVE

SUPPLY

PIPE

HOSE

UNIONS

SERVICING

VALVE

TEMPORARY

HOSE

HEATING

SYSTEM

HEATING

SYSTEM

TEMPORARY

HOSE

HOSE

UNIONS

SERVICING

VALVE

SUPPLY

PIPE

SUPPLY STOP

VALVE

DOUBLE CHECK

VALVE ASSEMBLY

HEATING

SYSTEM

SERVICING

VALVE

SUPPLY

STOP VALVE

SUPPLY

PIPE

HOSE

UNIONS

DOUBLE CHECK

VALVE ASSEMBLY

OVERFLOW

CISTERN

COMBINED

CHECK VALVE

AND VACUUM

BREAKER

PRESSURE

REDUCING

VALVE

0051

M

2 Water Sytem

2.12 Pressure Gauge

A pressure gauge with a set pointer and covering at least 0 to

4bar (0 to 60lb/in

2

) shall be fitted permanently to the system is

a position where it can be seen when filling the system.

2.13 Domestic Hot Water Cylinder

SINGLE FEED INDIRECT CYLINDERS ARE NOT SUITABLE.

The hot water cylinder must be of the indirect coil type. It must

be suitable for working at a gauge pressure of 0.35bar above

the safety valve setting.

2.14 Water Makeup

Provision should be made for replacing water loss from the

system using a make up bottle or filling loop mounted in a

position higher than the top point of the system, connected

through a non-return valve to the return side of either the

heating circuit or the hot water cylinder.

Alternatively, provision for make up can be made using a filling

loop.

2.15 Filling a Sealed Water System

Provision for filling the system at low level must be made. Three

methods are shown in diagram 2.5. There must be no permanent

connection to the mains water supply, even through a non-

return valve.