Split System Models

59

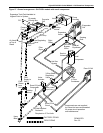

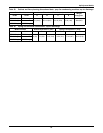

Figure 31 Refrigerant piping diagram

7.3.2 Quick Connect Fittings

Be especially careful when connecting the quick connect fittings. Read through the following steps

before making the connections.

1. Remove protector caps and plugs.

2. Carefully wipe coupling seats and threaded surfaces with a clean cloth.

3. Lubricate the male diaphragm and synthetic rubber seal with refrigerant oil.

4. Thread the coupling halves together by hand to ensure that the threads mate properly.

5. Tighten the coupling body hex nut and union nut with the proper sized wrench until the coupling

bodies “bottom out” or until a definite resistance is felt.

6. Using a marker or pen, make a line lengthwise from the coupling union nut to the bulkhead.

7. Tighten the nuts an additional quarter turn; the misalignment of the lines shows how much the

coupling has been tightened. This final quarter turn is necessary to ensure that the joint will not

leak. Refer to Table 24 for torque requirements.

8. Add charge for the additional piping (refer to Table 22).

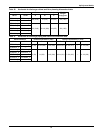

Table 24 Line coupling sizes

Model

(Tons)

Line Size

OD Cu, in.

Coupling

Size

Torque

lb-ft.

33/8 #610-12

5 1/2 & 5/8 #10 35-45

3 7/8 #11 35-45

5 1-1/8 #12 50-65

Table 25 Equivalent lengths (feet) for various pipe fittings

Copper Pipe

OD in.

90 Degree

Elbow Copper

90 Degree

Elbow Cast

45 Degree

Elbow Tee

Gate

Valve

Globe

Valve

Angle

Valve

1/2 0.8 1.3 0.4 2.5 0.26 7.0 4.0

5/8 0.9 1.4 0.5 2.5 0.28 9.5 5.0

3/4 1.0 1.5 0.6 2.5 0.3 12.0 6.5

7/8 1.45 1.8 0.8 3.6 0.36 17.2 9.5

1-1/8 1.85 2.2 1.0 4.6 0.48 22.5 12.0

1-3/8 2.4 2.9 1.3 6.4 0.65 32.0 16.0

1-5/8 2.9 3.5 1.6 7.2 0.72 36.0 19.5

Refrigerant trap = 4 times equivalent length of pipe per this table

NOTE

When hard piping is used, complete all piping and evacuate lines before

connecting quick connects.

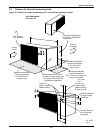

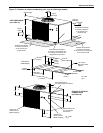

Evaporator

Condensing unit

Suction Line Piping

Condensing unit

above evaporator

Traps recommended at the base of riser and

every 25 feet (7.6m) of vertical rise.