Glycol/GLYCOOL-Cooled Models—Self-Contained Compressor

44

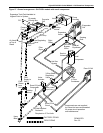

5.4.1 Expansion Tanks, Fluid Relief Valves and Other Devices

An expansion tank must be provided for expansion and contraction of the fluid due to temperature

change in this closed system. Vents are required at system high points to vent trapped air when fill-

ing the system. A relief valve is a also a necessary piping component.

Depending on the complexity of the system, various other devices may be specified. Pressure gauges,

flow switches, automatic air separator, tempering valves, standby pumps, sensors for electrical con-

trols, and flow switches are just a few of these devices.

NOTICE

Risk of freezing temperatures. Can cause equipment and piping damage.

Immediately following the use of water for leak testing or system cleaning, charge the tested

system with the proper percentage of glycol and water for your coldest design ambient.

Complete system drain-down cannot be assured and damage to the system could result from

freezing of residual water.

5.5 Filling Instructions

5.5.1 Preparing the System for Filling

It is important to remove any dirt, oil or metal filings that may contaminate the cooling system piping

in order to prevent contamination of the fresh glycol solution and fouling of the drycooler piping. The

system should be flushed thoroughly using a mild cleaning solution or high-quality water and then

completely drained before charging with glycol. Cleaning new systems is just as important as clean-

ing old ones. New systems can be coated with oil or a protective film; dirt and scale are also common.

Any residual contaminants could adversely affect the heat transfer stability and performance of your

system. In many cases, in both old and new systems, special cleaners are needed to remove scale, rust

and hydrocarbon foulants from pipes, manifolds and passages. Clean heat transfer surfaces are

important in maintaining the integrity of the heating/cooling system. For more information on clean-

ers and degreasers, contact your sales representative. Follow the manufacturer's instructions when

using these products.

Calculate the internal volume of the system as closely as possible. See Table 14 and Table 16 for

unit volumes. Use volume in Table 15 for glycol piping volumes.

Table 14 Indoor unit glycol volume approximate gallons (liters) max.

Model (50 Hz) Glycol-Cooled GLYCOOL

046WG/(045WG) 1.2 (4.5) —

071WG/(070WG) 2.0 (7.5) —

061G/(058G) — 4.0 (15.1)

Table 15 Volume in standard Type “L” copper piping

Diameter (in.) Volume

Outside Inside Gal/Ft L/M

1/2 0.123 0.008 0.01

5/8 0.555 0.012 0.15

3/4 0.666 0.018 0.22

7/8 0.785 0.025 0.31

1-1/8 1.025 0.043 0.53