5

5

Step 2: Determine whether the boiler is to be installed in a confi ned space

A confi ned space is defi ned by the National Fuel Gas Code as having a volume less than 50 cubic feet per 1000 BTU/hr

input of all appliances installed in that space. To determine whether the boiler room is a confi ned space:

1) Total the input of all appliances in the boiler room in thousands of BTU/hr. Round the result to the next highest 1000 BTU/

hr.

2) Find the volume of the room in cubic feet. The volume of the room in cubic feet is:

Length (ft) x width (ft) x ceiling height (ft)

In calculating the volume of the boiler room, consider the volume of adjoining spaces only if no doors are installed between

them. If doors are installed between the boiler room and an adjoining space, do not consider the volume of the adjoining

space, even if the door is normally left open.

3) Divide the volume of the boiler room by the input in thousands of BTU/hr. If the result is less than 50, the boiler room is a

confi ned space.

Example:

A CWD245 and a water heater are to be installed in a room measuring 6ft – 3 in x 7ft with an 8 ft ceiling. The water heater

has an input of 30000 BTU/hr:

Total input in thousands of BTU/hr = (245000 BTU/hr + 30000 BTU/hr) / 1000 = 275

Volume of room = 6.25 ft x 7 ft x 8 ft = 350 ft

3

350/275 = 1.27. Since 1.27 is less than 50, the boiler room is a confi ned space.

Step 3: Decide whether the boiler will be direct vented or direct exhausted

The boiler must be direct vented (combustion air piped directly to the boiler) if:

• The boiler is to be installed in a laundry room

• The building in which the boiler is installed has an indoor pool.

• The boiler is located in an area having any of the contaminants described in Section IV.

It is also strongly recommended that combustion air be piped from outside when the boiler is installed in a building of

unusually tight construction.

Step 4: If the boiler is Direct Vented, Provide Air as Follows (If Indoor Combustion Air is used,

Skip to Step 5):

1) Combustion air piping must not exceed the maximum lengths called for in Section VI.

2) Although combustion air is obtained directly from outdoors, openings may be required into the boiler room to allow for

adequate equipment ventilation. The following guidelines apply regardless of whether or not the building is of unusually

tight construction:

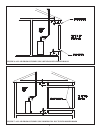

Unconfi ned Space– Natural infi ltration into the boiler room will provide adequate air for ventilation without additional

openings into boiler room.

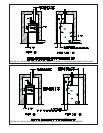

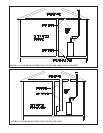

Confi ned Space – Provide two openings into the boiler room, one near the fl oor and one near the ceiling. The top edge of

the upper opening must be within 12” of the ceiling and the bottom edge of the lower opening must be within 12” of the

fl oor (Fig 3). The minimum opening dimension is 3 inches.

• If the CWD boiler is the only gas-burning appliance in the boiler room, these openings must each have a free area of 100

square inches.

• If other gas-burning appliances are in the boiler room, size the openings in accordance with the appliance manufacturer’s

instructions or the National Fuel Gas Code. Minimum opening free area is 100 square inches regardless of opening

requirements for other appliances.

• If the total volume of both the boiler room and the room to which the openings connect is less than 50 cubic feet per 1000

BTU/hr of total appliance input, install a pair of identical openings into a third room. Connect additional rooms with

openings until the total volume of all rooms is at least 50 cubic feet per 1000 BTU/hr of input.

• The “free area” of an opening takes into account the blocking effect of mesh, grills, and louvers. Where screens are used,

they must be no fi ner than ¼” (4 x 4) mesh.