Holes in brick masonry should be a half-inch larger diameter hole than the duct pipe to be utilized.

This will allow an area for expansion of the duct pipe as it heats up. Example: if ducting a Country

Flame Model 33, a 6-½ inch diameter hole should be cut in the masonry for the duct: whereas, for the

Model 37 and the Model 42, an 8-½ inch diameter hole should be cut in the masonry for the duct. All

clearances listed in Table 1, page 2 must be strictly adhered to.

FIGURE 15 shows a side (one side only for clarity) view of the optional side vent fireplace. To order

this optional side vented fireplace furnace, contact a Country Flame dealer or Country Flame direct.

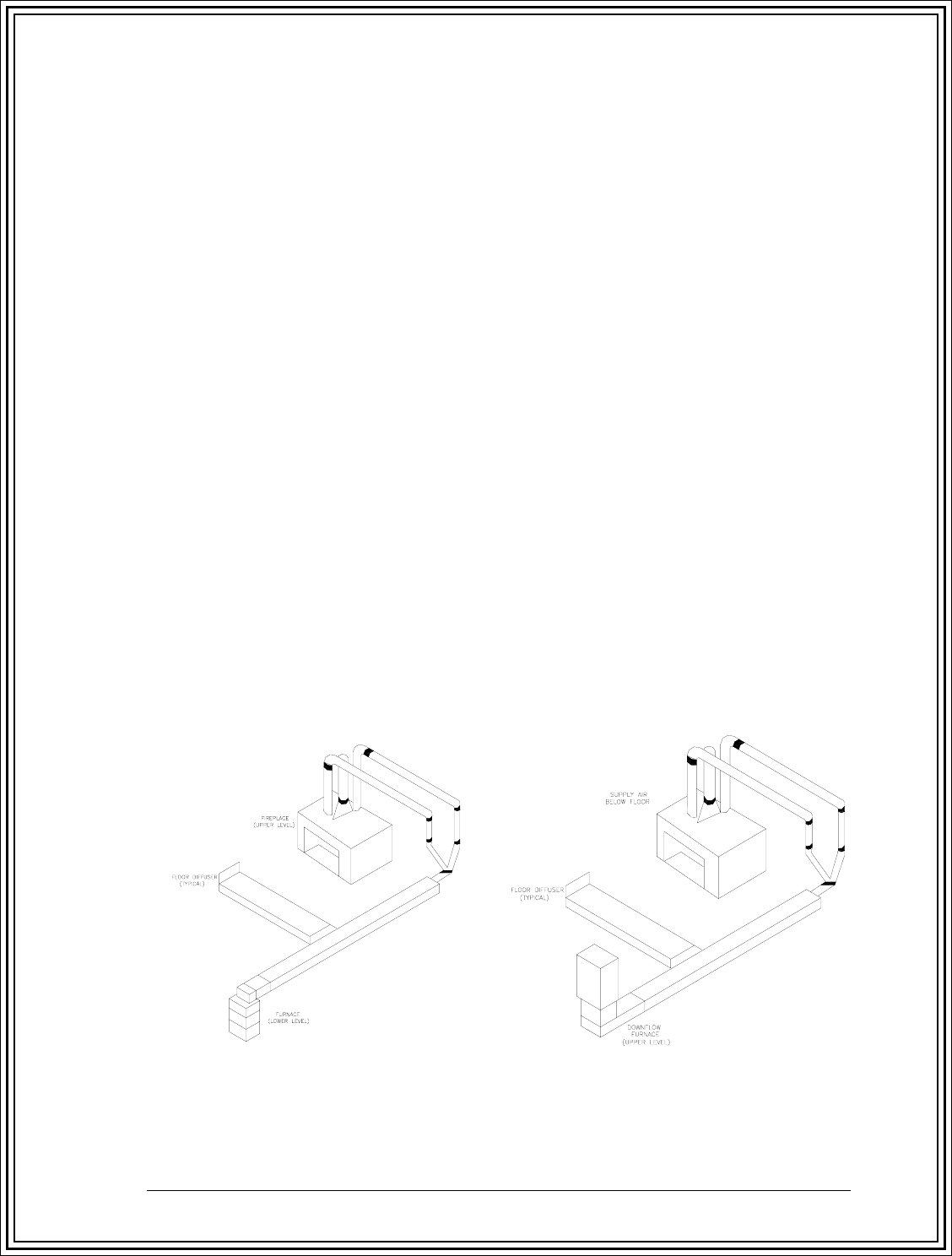

FIGURE 16 provides a view of several different options that are possible for connecting fireplace

furnace ducting systems. Clearly, a plan must be developed for how the ducts will be connected before

installation is begun or completed. The following steps will assist in properly installing ductwork but

local codes and your home’s HVAC expert should be consulted.

1. Use 26 gauge or heavier galvanized pipes for ducting. WARNING: DO NOT use plastic

or flex ducting. The ductwork must be wrapped with two inches of insulation as per table

10-D of the Uniform Mechanical Code (UMC) within the masonry cavity.

2. Wrap the duct pipe for the first fifteen feet out of the masonry cavity with a minimum of

two inches of insulation as per 10-D of the UMC. After fifteen feet no insulation is

required but is HIGHLY RECOMMENDED in order to minimize heat loss.

WARNING: Maintain a minimum clearance of at least three inches to all combustible

materials over the entire length of the ductwork.

3. Ducts must have adequate straps or other means of securing the ductwork to prevent

sagging or movement.

4. Do not reduce the size of the ductwork. Avoid using 90

o

elbows where possible. Two 45

o

elbows are preferable to a single 90

o

elbow and will minimize pressure drops within the

ductwork system.

FIGURE 16a: DUCTING SYSTEMS EXAMPLES

Version 7.1

24