8

Gas Fireplace Insert

10002964

Leveling Bar

Set Screws

FP1658

Fig. 8 Adjust leveling bar on A132 only.

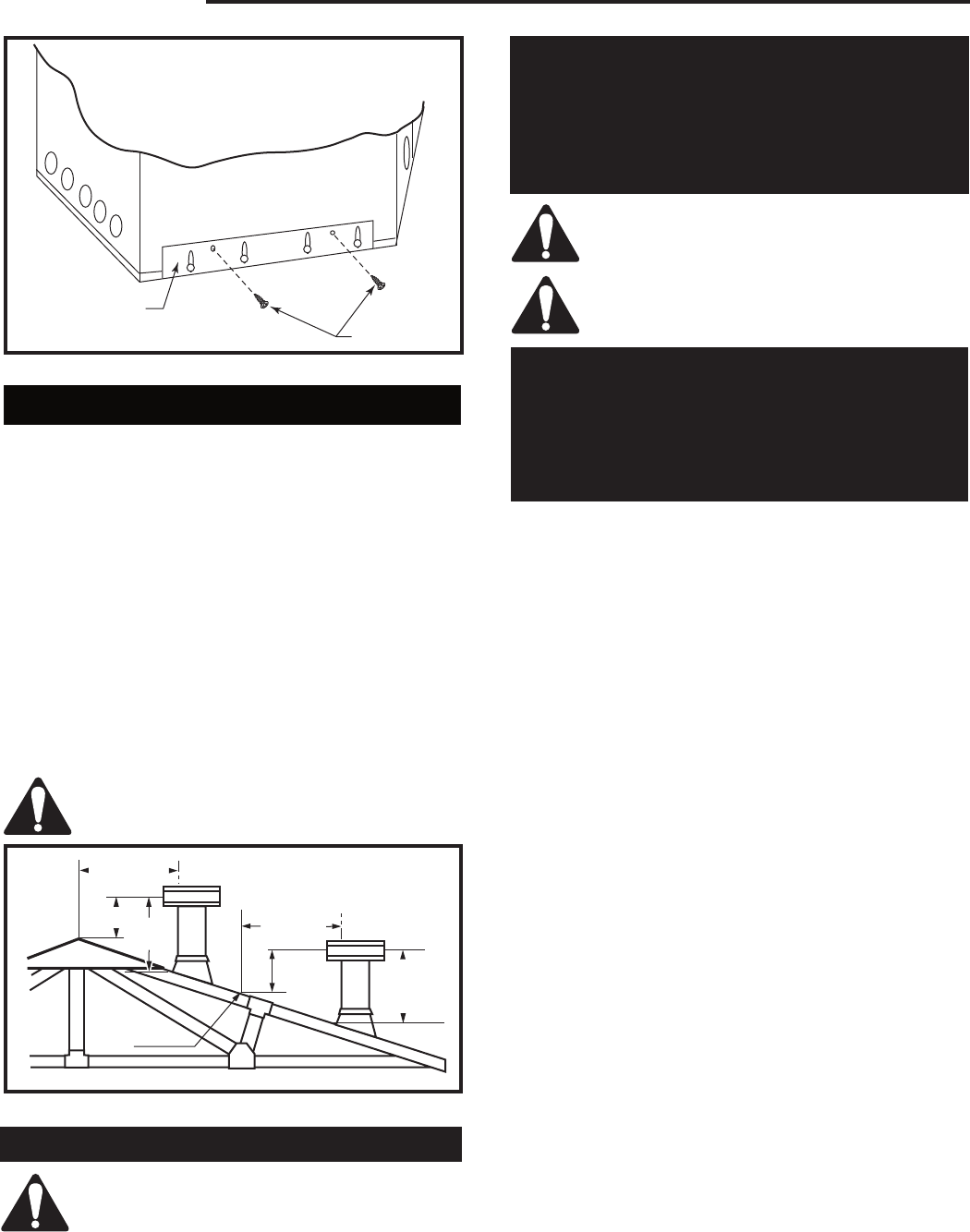

2' Min.

2'

(610mm)

Min.

3'

Min.

0 To 10'

3'

(914mm)

Min.

0 To 10'

AC246

4/1/96

Reference

Point

(3m)

Fig. 9 Example of the 2', 3', 10' rule.

AC246a

Venting and Installation

Installer must attach red warning label to

fireplace.

WARNING

This fireplace has been converted for use with

gas only and cannot be used for burning wood

or solid fuels unless all original parts have been

replaced and the fireplace has been re-approved

by the authority having jurisdiction.

Cutting any sheet metal parts of the fire-

place, in which the gas fireplace insert is

to be installed, is prohibited.

Ensure there are no obstructions to side

air passages of decorative trim once in-

stalled on insert.

WARNING

Some factory built fireplaces have air passages

on face of fireplace for zero clearance capabili-

ties. All trim kits are designed so as to allow air-

flow to these passages. Under no circumstances

should these passages be blocked.

Venting Instructions

Canadian Installations:

The venting system must be installed in accordance

with the current CSA-B149.1 installation code, and the

authority having jurisdiction.

U.S.A. Installations:

The venting system must be installed in accordance

with the current National Fuel Gas Code, ANSI Z223.1/

NFPA 54.

Minimum clearances to combustible materials is 1" (25

mm) for B Vent (use of single wall vent is not al-

lowed).

As with any natural draft appliances, the vent cap must

always extend a minimum of 2' (610 mm) above any

structure within a 10' (3 m) horizontal plane. (Fig. 9)

A minimum 12’ (3.7 m) vent height is re

-

quired to effectively vent this fireplace.

1. Gas inserts are designed for recessed

installations into solid fuel masonry or factory built

noncombustible fireplaces that have been installed

in accordance with the National, Provincial, State

and local building codes.

2. Measure for minimum fireplace opening requirement

on Page 4 of this installation manual. (If firebrick

[refractory] is removed from a factory built

fireplace in order to gain minimum gas fireplace

insert opening requirements, a minimum of 1/4"

(6 mm) air space is required between the gas

insert fireplace's outer casing and the inner wall

of the factory built fireplace).

3. To assure top performance, safety and efficiency,

all inserts must be installed with an approved 4"

diameter flue liner, with exception of A125, which

should be installed with an approved 3" liner,as per

CSA-B.149 or National Fuel Code ANSI Z223/NFPA

54.

4. Flue damper must be fully blocked in the open

position or removed for installation.

5. The chimney must be clean and in good working

order and constructed of noncombustible materials.

6. Make sure that all chimney cleanouts fit properly so

air cannot leak into the chimney.

7. Glass door, screen kits and log grate may be

removed for installation of insert into factory built

fireplace.

8. Install the insert without the trim frame and make all

gas, venting and electrical connections.

9. Install decorative trim frame. Please refer to Frame

Assembly and Mounting instructions In this manual.