16

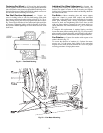

Condensate Drain — Install a trapped condensate drain

line to unit connection as shown in Fig. 12. The unit drain con-

nection is a PVC stub. See Fig. 13. Some areas may require an

adapter to connect to either galvanized steel or copper pipe.

For these applications, install a field-supplied threaded PVC

adapter.

Fig. 12 — Condensate Drains

NOTE: A trap must be installed in the condensate drain

line to ensure that the static pressure of fans is balanced

with the water column in the drain line and that condensate

can drain completely from pan. Without a trap, air can be

drawn up drain line until water level in condensate pan

becomes equal to static pressure created by fans, preventing

complete drainage. Conditions will worsen as filters

become dirty.

Install clean-out plugs in trap. Pitch drain line downward to an

open floor drain or sump. Provide service clearance around

drain line to permit removal of unit panels. Observe all local

sanitary codes.

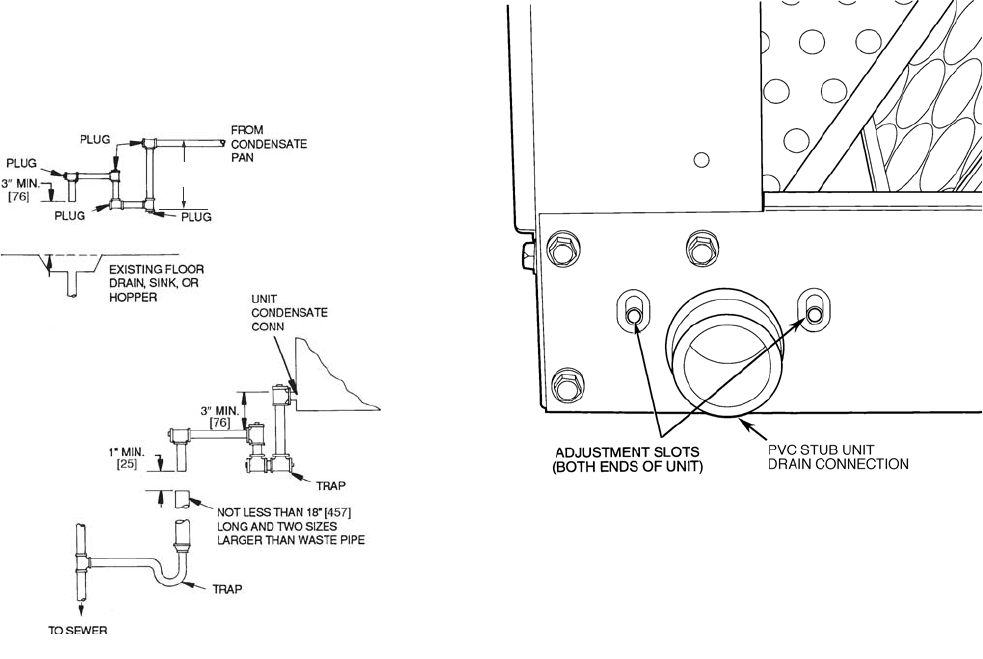

Fig. 13 — Drain Pan Slope Adjustment

As shipped, the unit’s condensate drain pan is NOT sloped to-

wards the drain connection. The pan slope must be changed to

pitch towards the side of the unit with the drain connection. See

Fig. 13. Loosen the 2 screws next to the drain outlet at both

ends of the unit, push drain pan down in the slots near the drain

connection, and up in the slots on the opposite end. Retighten

screws. The pan should have a pitch of at least

1

/

4

-in. over its

length toward the drain connection.

Fan Motors and Drives — Motor and drive packages

are factory installed in all units. The motor and drive packages

consist of the following items:

1 — fan motor

1 — adjustable motor pulley

1 — fan pulley

2 — matched fan belts (40RUA*25-30, 40RUS*25-30 units)

For instructions on changing fan rotation, changing drive

speeds and adjusting drives, see Pulley and Drive Adjustment

in the Service section.

3” MIN.

[76]

NOTE: Dimensions in [ ] are in millimeters