20

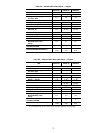

Table 6 — Fan Contactor Coil Data

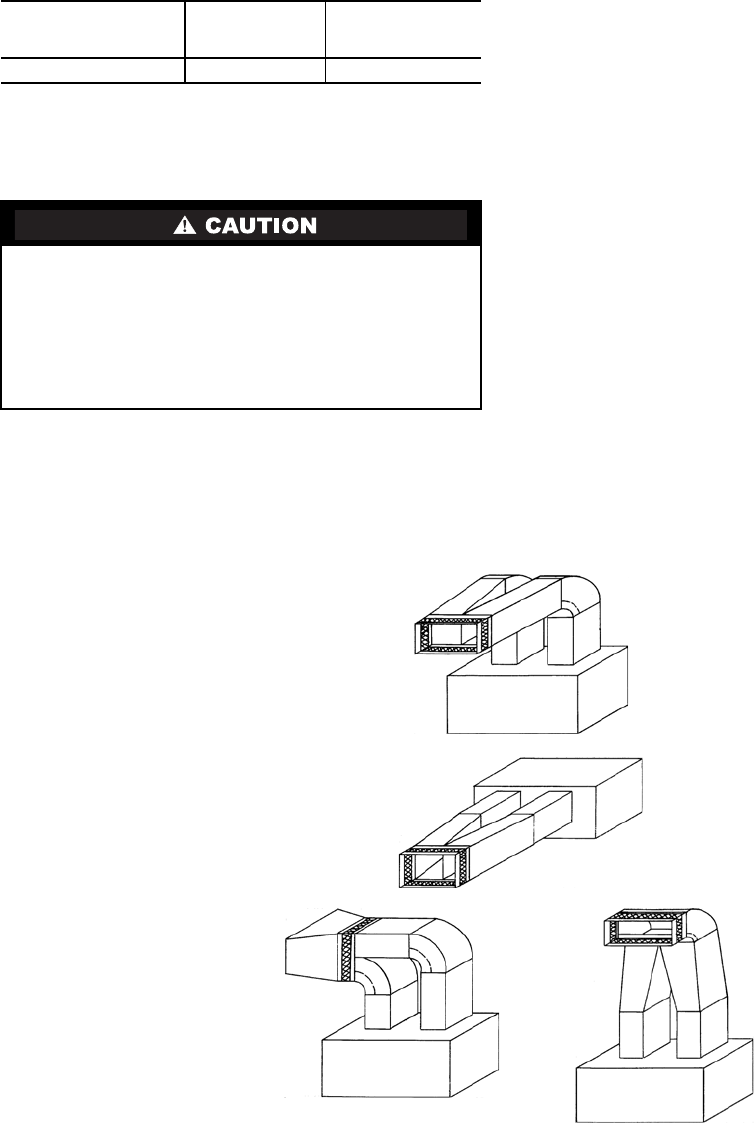

Connecting Ductwork — Refer to the Carrier System

Design Manual for the recommended design and layout of

ductwork. Fig. 18 shows recommended duct connection to

units with 2 fans.

DISCHARGE CONNECTIONS — Duct flanges are

factory-supplied; they are shipped inside the unit attached to

the hairpin end of the coil tube sheet for field installation.

Using the existing screws, install the duct flanges on the unit’s

fan deck. Each fan discharge requires 2 flanges; each flange

must be bent in the middle to conform to the discharge

opening. See Fig. 19. After flanges are installed, connect them

to the supply duct using a canvas connection to prevent

vibration. It is important that this connection be properly

fabricated to prevent high air friction losses and air noise.

RETURN CONNECTION — When using return-air

ductwork, route return-air duct to the unit’s return air inlet near

the filter rack, using a canvas connection to prevent

transmission of unit vibration. If the duct blocks off the unit’s

access panel, provide a slip joint in the ductwork to permit

removal for servicing.

OUTDOOR-AIR INLET CONNECTION — Connect outdoor-

air inlet to field-installed accessory economizer. Refer to

Economizer Installation Instructions.

Return-Air Filters — Type and size of filters are shown

in Tables 1A – 1D and are factory-supplied and factory-

installed. In all units with 2 fans, a filter replacement tool

(hook) is shipped inside the unit for field use when replacing

filters. See the Service section for instructions on filter element

replacement.

Fig. 18 — Typical Fan Discharge Connections for Multiple Fan Units

UNIT

40RU**

VOLTAGE

(vac)

MAXIMUM

HOLDING

VA

25, 28, 30 24 10

UNIT OPERATION HAZARD

Failure to follow this caution could cause equipment

damage.

Do not operate unit without ductwork or discharge plenum

unless fan speed has been adjusted for external static

pressure of zero in. wg. Failure to do so may result in

motor overload.