11

Unit Isolation — Where extremely quiet operation is

essential, install isolators between floor and base of unit, or

between ceiling and top section of unit.

Be sure that unit is level and adequately supported. Use

channels at front and sides of unit for reference points when

leveling.

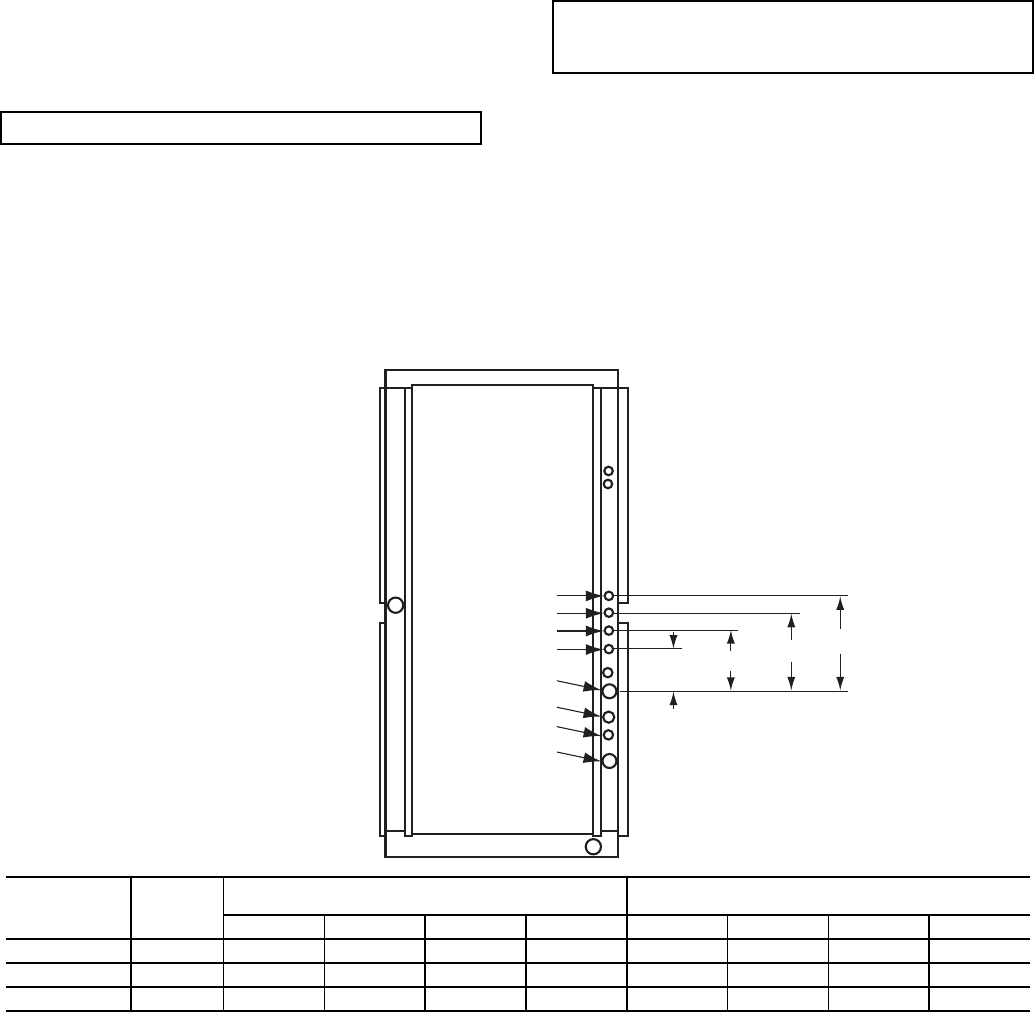

Refrigerant and Chilled Water Piping

Access —

The 40RU Series units come with standard

knockouts for refrigerant and chilled water piping. These

knockouts are located on both sides of the unit for installation

flexibility. The standard knockouts provide sufficient access to

the unit’s coils for all 40RUA*25, 28, and 30 units. RUS*25,

28, and 30 units require additional holes which must be field-

fabracated to accomodiate the piping. See Fig. 7 for the

positions and dimensions of the additional access holes

required for the RUS units. Recommended access hole use is

also listed for all units. Note that Fig. 7 shows the access holes

on the control-box side of the unit; this is the side of the unit

with the coil headers, so it is used most often for piping access.

Refrigerant Piping — See Tables 1A–1D for refrigerant

pipe connection sizes. For ease in brazing, it is recommended

that all internal solder joints be made before unit is placed in

final position.

The 40RU direct-expansion units have internal

factory-installed thermostatic expansion valves (TXVs),

distributors, and nozzles for use with R-410A. See Table 2

for part numbers. Knockouts are provided in the unit corner

posts for 40RU refrigerant piping. See Fig. 7, which also

lists recommended knockouts and access holes to use for

each 40RU unit size. Recommended fittings are listed in

Table 3.

The sensor bulb capillary tubes must be routed from the TXVs

inside the unit through one of the piping access holes. Clamp

the TXV sensor bulb on a vertical portion of the suction line,

outside the unit. See Fig. 8.

NOTE: Be sure to remove the styrofoam shipping pad from

the TXV. Verify that it has been removed. See Fig. 1.

The 40RU Series evaporator coils have a face-split design.

Ensure that lower circuit of coil is first on/last off when

connected to the condensing unit and/or system controls. See

Fig. 9.

External TXV equalizer connections are provided and

factory-brazed into the coil suction manifolds.

If suction line must be horizontal, clamp bulb to suction line at

least 45 degrees above bottom, at approximately the 4 o’clock

or 8 o’clock position. See Fig.10.

Fig. 7 — Refrigerant and Chilled Water Piping Access Holes

IMPORTANT: Do not bury refrigerant piping underground.

IMPORTANT: Never attach the sensor to the suction

manifold. Do NOT mount the sensor on a trapped portion

of the suction line.

4

3

2

1

7

6

5

A

B

C

D

8

UNIT

USE HOLE

NUMBERS

FIELD-FABRICATED HOLE DIAMETERS

in. (mm)

FIELD-FABRICATED HOLE POSITION

DIMENSIONS, in. (mm)

No. 5No. 6No. 7No.8ABCD

40RUA*25, 28, 30 1, 2, 3, 4————————

40RUS*25 4, 5, 6, 7 1

3

/

4

(44.5) 1

3

/

4

(44.5) 1

3

/

4

(44.5) — 3.0 (76.2) 6.0 (152.5) 10.5 (266.7)

40RUS*28, 30 5, 6, 7, 8 2

1

/

2

(63.5) 2

1

/

2

(63.5) 2

1

/

2

(63.5) 2

1

/

2

(63.5) 6.0 (152.5) 9.625 244.5) 13.38 (339.9) 17.0 (431.8)