The alarm codes for the IGC control board are shown in

Table 22.

Table 22 — IGC Control Board LED Alarms

INDICATION ERROR MODE

ON Normal Operation

OFF Hardware Failure

1 FLASH Fan ON/OFF Delay Modified

2 FLASHES Limit Switch Fault

3 FLASHES Flame Sense Fault

4 FLASHES 4 Consecutive Limit Switch Faults

5 FLASHES Ignition Lockout Fault

6 FLASHES Induced Draft Motor Fault

7 FLASHES Rollout Switch Fault

8 FLASHES Internal Control Fault

Diagnostic LEDs — There are 3 LEDs (red, yellow,

and green) on the lower right hand side of the control board.

The red light is used to check unit operation and alarms. A

constant pulse is normal unit operation. A series of quick

blinks indicates an alarm. Refer to Table 23 below for a de-

scription of alarms. The yellow LED blinks during transmis-

sion with the CCN (Carrier Comfort Network). The green

LED blinks during transmission with the expansion board.

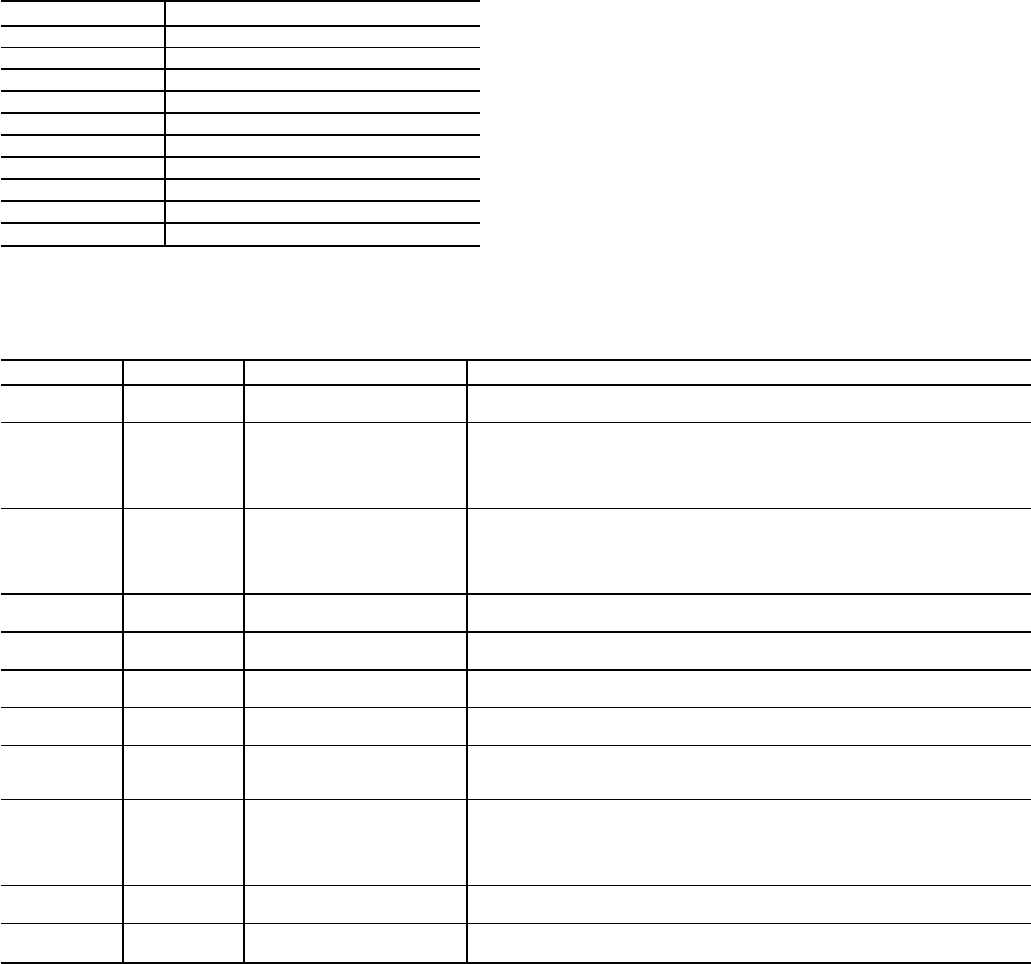

Table 23 — Control Board LED Alarms

LED Blinks Error Code Description Troubleshooting Comments

1 — Normal Operation

The expansion board and control board flash the red LED in one-second

intervals when the board is operating properly.

2 HF-13 Compressor 1 Safety

The high orlow pressure safety switch for compressor no.1 has opened for

3 seconds. The error will be cleared and compressor no. 1 will be allowed

to turn on in 15 minutes. If the safeties have been tripped 3 times in 90 min-

utes, compressor no. 1 will be locked out until the control board has been

manually reset.

3 HF-14 Compressor 2 Safety

The high orlow pressure safety switch for compressor no.2 has opened for

3 seconds. The error will be cleared and compressor no. 2 will be allowed

to turn on in 15 minutes. If the safeties have been tripped 3 times in 90 min-

utes, compressor no. 2 will be locked out until the control board has been

manually reset.

4 HF-15 Thermostat Failure

The thermostat iscalling for both heating and cooling at the same time. The

unit will operate on a first call basis and will automatically reset.

5 HF-05 SAT Thermistor Failure

The supply-air temperature (SAT) sensor has failed. First check for wiring

errors, then replace sensor.

6 HF-06 OAT Thermistor Failure

The outside air temperature (OAT) sensor has failed. First check for wiring

errors, then replace sensor.

7 HF-03 Space Temp. Sen. Failure

The space temperature sensor has failed. First check for wiring errors, then

replace sensor.

8 HF-12 RAT Thermistor Failure

The return-air temperature (RAT) sensor has failed. Ensure that the unit is

a VAV unit. If NOT a VAV unit set DIP switch position 1 to the closed position

and reset power. Then check for wiring errors. Finally, replace sensor.

9 SE-05

Loss of Communications

with Expansion Board

Communications between the expansion board and the control board have

been interrupted. Ensure that an expansion board is installed and wired us-

ing the wire harness supplied with the expansion module. If an expansion

board is not used ensure that DIP switch position 3 is in theclosed position,

and reset power.

10 HF-16 Control Board Failure

Generated when hardware has failed on control board. Replace the control

board.

11 HF-17 Expansion Board Failure

Generated when hardware has failed on the expansion board. Replace the

expansion board.

DIP — Dual In-Line Package

VAV — Variable Air Volume

60