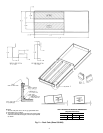

ALTERNATE UNIT SUPPORT — When the preferred curb

or slab mount cannot be used, support unit with sleepers on

perimeter, using unit curb support area. If sleepers cannot be

used, support long sides of unit (refer to Fig. 3-6) with a

minimum number of 4-in. x 4-in. pads spaced as follows:

48EJ,EK,EW,EY024-034 units require 3 pads on each side;

48EJ,EK,EW,EY038-048 units require 4 pads on each side.

Unit may sag if supported by corners only.

Step 2 — Rig and Place Unit — Inspect unit for trans-

portation damage. File any claim with transportation agency.

Do not drop unit; keep upright. Use spreader bars over

unit to prevent sling or cable damage. Level by using unit

frame as a reference; leveling tolerance is shown in Fig. 1

and 2. See Fig. 7 for additional information. Unit operating

weight is shown in Table 1.

NOTE: On retrofit jobs, ductwork may be attached to old

unit instead of roof curb. Be careful not to damage ductwork

when removing old unit. Attach existing ductwork to roof

curb instead of unit.

Four lifting lugs are provided on theunit base rails as shown

in Fig. 7. Refer to rigging instructions on unit.

POSITIONING — Maintain clearance, per Fig. 3-6, around

and above unit to provide minimum distance from combus-

tible materials, proper airflow, and service access.

Do not install unit in an indoor location. Do not locate

unit air inlets near exhaust vents or other sources of con-

taminated air. For proper unit operation, adequate combus-

tion and ventilation air must be provided in accordance with

Section 5.3 (Air for Combustion and Ventilation) of the

National Fuel Gas Code, ANSI Z223.1 (American National

Standards Institute).

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

Locate mechanical draft system flue assembly at least

4 ft from any opening through which combustion products

could enter the building, and at least 4 ft from any adjacent

building. When unit is located adjacent to public walkways,

flue assembly must be at least 7 ft above grade.

ROOF MOUNT — Check building codes for weight distri-

bution requirements. Unit weight is shown in Table 1.

Step 3 — Field Fabricate Ductwork

48EJ,EK UNITS — Field-fabricated ductwork should be at-

tached to the roof curb. Supply and return duct dimensions

are shown in Fig. 3 and 4. Air distribution is shown in

Fig. 8.

To attach ductwork to roof curb, insert duct approxi-

mately 10 to 11 in. up into roof curb. Connect ductwork to

14-gage roof curb material with sheet metal screws driven

from inside the duct.

Secure all ducts to the building structure, using flexible

duct connectors betweenroof curb and ducts as required. Ducts

passing through an unoccupied space must be insulated and

covered with a vapor barrier. Outlet grilles must not lie

directly below unit discharge. The return duct must have a

90-degree elbow before opening into the building space if

the unit is equipped with power exhaust.

For vertical supply and return units, tools or parts could

drop into ductwork and cause an injury. Install 90 de-

gree elbow turns in the supply and return ductwork be-

tween the unit and the conditioned space. If a 90 degree

elbow cannot be installed, then grilles of sufficient strength

and density should be installed to prevent objects from

falling into the conditioned space.

48EW,EY UNITS — Remove shipping covers from supply

and return air openings. Attach field-supplied ductwork to

unit. Use a single duct over both return openings and a single

duct over both supply openings. See Fig. 5 and 6 for duct

opening dimensions. Secure all ducts to the building struc-

ture. See Fig. 9. Use flexible duct connectors between unit

and ducts as required. Insulate and weatherproof all external

ductwork, joints, and building openings with counter flash-

ing and mastic in accordance with applicable codes.

Ducts passing through an unconditioned space must be

insulated and covered with a vapor barrier.

Install accesssory barometric relief or power exhaust in

the field-fabricated return ductwork. Refer to Position Power

Exhaust/Barometric Relief Damper Hood section on

page 26 for more information.

Instructions continued on page 12.

2