16

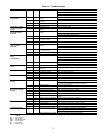

Table 8 — Approximate Fluid Volume (L)

per 30 M of Pipe

LEGEND

NOTE: Volume of heat exchanger is approximately 1.0 gallon

(3.78 liters).

Table 9 — Antifreeze Percentages by Volume

Cooling Tower/Boiler Systems — These systems

typically use a common loop maintained at 15.6 to 32.2 C. The

use of a closed circuit evaporative cooling tower with a second-

ary heat exchanger between the tower and the water loop is rec-

ommended. If an open type cooling tower is used continuously,

chemical treatment and filtering will be necessary.

Ground Coupled, Closed Loop and Plateframe

Heat Exchanger Well Systems — These systems al-

low water temperatures from –1.1 to 43.3 C. The external loop

field is divided up into 51 mm polyethylene supply and return

lines. Each line has valves connected in such a way that upon

system start-up, each line can be isolated for flushing using only

the system pumps. Air separation should be located in the pip-

ing system prior to the fluid re-entering the loop field.

OPERATION

Power Up Mode —

The unit will not operate until all the

inputs, terminals and safety controls are checked for normal

operation.

NOTE: The compressor will have a 5-minute anti-short cycle

upon power up.

Units with Aquazone™ Complete C Control

STANDBY — The Y and W terminals are not active in Stand-

by mode, however the O and G terminals may be active, de-

pending on the application. The compressor will be off.

COOLING — The Y and O terminals are active in Cooling

mode. After power up, the first call to the compressor will initi-

ate a 5 to 80 second random start delay and a 5-minute anti-

short cycle protection time delay. After both delays are com-

plete, the compressor is energized.

NOTE: On all subsequent compressor calls the random start

delay is omitted.

HEATING STAGE 1 — Terminal Y is active in heating

Stage 1. After power up, the first call to the compressor will

initiate a 5 to 80 second random start delay and a 5-minute anti-

short cycle protection time delay. After both delays are

complete, the compressor is energized.

NOTE: On all subsequent compressor calls the random start

delay is omitted.

HEATING STAGE 2 — To enter Stage 2 mode, terminal W is

active (Y is already active). Also, the G terminal must be active

or the W terminal is disregarded.

Units with Aquazone Deluxe D Control

STANDBY — The compressor will be off. The reversing

valve (RV) relays will be on if inputs are present.

HEATING STAGE 1 — In Heating Stage 1 mode, the fan en-

able and compressor relays are turned on immediately. Once

the demand is removed, the relays are turned off and the con-

trol reverts to standby mode. If there is a master/slave or dual

compressor application, all compressor relays and related func-

tions will operate per their associated DIP switch 2 setting on

S1.

HEATING STAGE 2 — In Heating Stage 2 mode, the com-

pressor relays remain on. The control reverts to Heating Stage

1 mode once demand is removed. If there is a master/slave or

dual compressor application, all compressor relays and related

functions will operate per their associated DIP switch 2 setting

on S1.

COOLING STAGE 1 — In Cooling Stage 1 mode, the com-

pressor and RV relays are turned on immediately. If configured

as stage 2 (DIP switch set to OFF) then the compressor and fan

will not turn on until there is a stage 2 demand. The compressor

relays are turned off immediately when the Cooling Stage 1 de-

mand is removed. The control reverts to standby mode. The

RV relay remains on until there is a heating demand. If there is

a master/slave or dual compressor application, all compressor

relays and related functions will track with their associated DIP

switch 2 on S1.

COOLING STAGE 2 — In Cooling Stage 2 mode, the com-

pressor and RV relays remain on. The control reverts to Cool-

ing Stage 1 mode once the demand is removed. If there is a

master/slave or dual compressor application, all compressor re-

lays and related functions will track with their associated DIP

switch 2 on S1.

NIGHT LOW LIMIT (NLL) STAGED HEATING — In NLL

staged heating mode, the override (OVR) input becomes

active and is recognized as a call for heating and the control

will immediately go into a Heating Stage 1 mode. With an

additional 30 minutes of NLL demand, the control will go into

Heating Stage 2 mode. With another additional 30 minutes of

NLL demand, the control will go into Heating Stage 3 mode.

SYSTEM TEST

System testing provides the ability to check the control

operation. The control enters a 20-minute Test mode by mo-

mentarily shorting the test pins. All time delays are increased

15 times. See Fig. 11.

Test Mode — Enter the Test mode on Complete C or

Deluxe D controls by momentarily shorting the test terminals.

The Complete C or Deluxe D control will enter a 20-minute

test mode period in which all time delays are sped up 15 times.

PIPE DIAMETER (in.) [mm] VOLUME (gal.) [L]

Copper 1 [25.4] 4.1 [15.5]

1.25 [31.8] 6.4 [24.2]

1.5 [38.1] 9.2 [34.8]

Rubber Hose 1 [25.4] 3.9 [14.8]

Polyethylene

3

/

4

IPS SDR11 2.8 [10.6]

1 IPS SDR11 4.5 [17.0]

1

1

/

4

IPS SDR11 8.0 [30.8]

1

/

2

IPS SDR11 10.9 [41.3]

2 IPS SDR11 18.0 [68.1]

1

1

/

4

IPS SCH40 8.3 [31.4]

1

1

/

2

IPS SCH40 10.9 [41.3]

2 IPS SCH40 17.0 [64.4]

IPS — Internal Pipe Size

SCH — Schedule

SDR — Standard Dimensional Ratio

ANTIFREEZE

MINIMUM TEMPERATURE FOR FREEZE

PROTECTION (C)

–12.2 –9.4 –6.7 –3.9

Methanol (%) 25 21 16 10

100% USP Food Grade

Propylene Glycol (%)

38 30 22 15

Ethanol (%) 29 25 20 14

C

R

R

C

CC

CCG

BR

BRG

Test

Off On

FP1JW3

TEST

MODE

PINS

Fig. 11 — Test Mode Pins Location