91

Lubrication

COMPRESSORS — Each compressor is charged with the

correct amount of oil at the factory. The correct oil charge is

shown in Tables 1A and 1B. If oil is visible in the compressor

sight glass, check unit for operating readiness as described in

Start-Up section, then start the unit. Observe oil level and add

oil, if required, to bring oil level in compressor crankcase up to

between

1

/

4

and

1

/

3

of sight glass during steady operation.

If oil charge is above

1

/

3

sight glass, do not remove any oil

until the compressor crankcase heater has been energized for at

least 24 hours with compressor off.

When additional oil or a complete charge is required, use

only Carrier-approved compressor oil:

Petroleum Specialties, Inc. . . . . . . . . . . . . . . . . . . . . . Cryol 150

Texaco, Inc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Capella WF-32

Witco Chemical Corp. . . . . . . . . . . . . . . . . . . . . . . Suniso 3GS

FAN SHAFT BEARINGS — Lubricate bearings at least ev-

ery 6 months with suitable bearing grease. Do not over grease.

Typical lubricants are given below:

*Preferred lubricant because it contains rust and oxidation inhibitors.

CONDENSER- AND EVAPORATOR-FAN MOTOR

BEARINGS — The condenser- and evaporator-fan motors

have permanently-sealed bearings, so no field lubrication is

necessary.

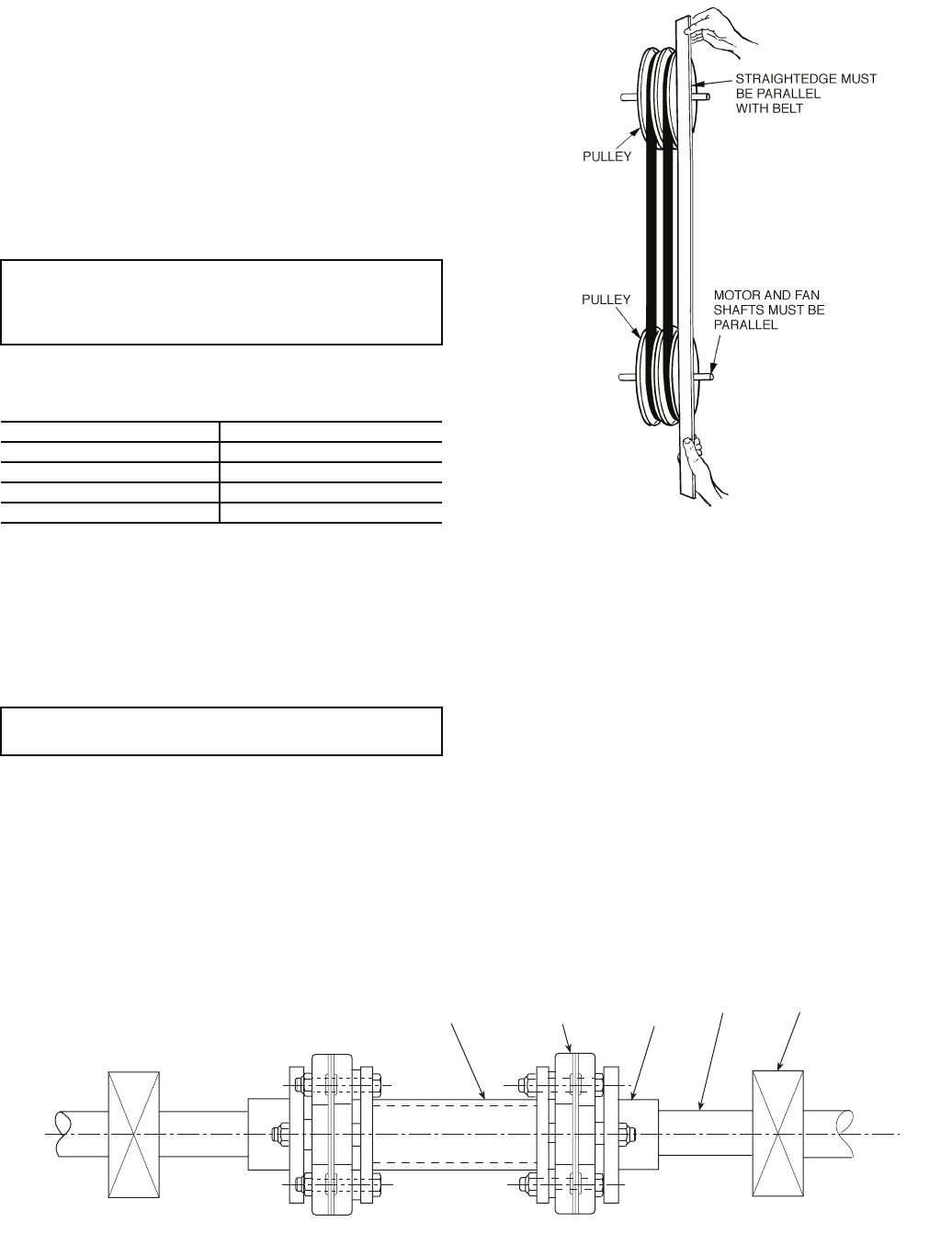

Evaporator Fan Performance Adjustment

(Fig. 67) — Fan motor pulleys are designed for speed

shown in Tables 1A and 1B (factory speed setting).

To change fan speeds, change pulleys.

To align fan and motor pulleys:

1. Shut off unit power supply.

2. Loosen fan shaft pulley bushing.

3. Slide fan pulley along fan shaft.

4. Make angular alignment by loosening motor from

mounting plate.

5. Retighten pulley.

6. Return power to the unit.

Evaporator Fan Coupling Assembly — If the cou-

pling has been removed for other blower assembly component

repair or replacement, it is critical that the coupling be reassem-

bled and aligned correctly to prevent premature failures.

REASSEMBLING THE COUPLING INTO THE UNIT

(Fig. 68)

1. Prior to reassembling the coupling, loosen the 4 bearing

mounting bolts, which secure the 2 bearings on either side

of the coupling. Remove the drive belts.

2. Reassemble the coupling with the bearings loose. This al-

lows the coupling to find its own self-alignment position.

3. Check the hub-to-shaft fit for close fitting clearances.

Replace hubs if high clearances are determined.

4. Check the key for close-fitted clearances on the sides and

0.015 in. clearance over the top of the key. Replace key if

necessary.

IMPORTANT: Do not use reclaimed oil or oil that has

been exposed to the atmosphere. Refer to Carrier Standard

Service Techniques Manual, Chapter 1, Refrigerants sec-

tion, for procedures to add or remove oil.

MANUFACTURER LUBRICANT

Texaco Regal AFB-2*

Mobil Mobilplex EP No. 1

Sunoco Prestige 42

Texaco Multifak 2

IMPORTANT: Check to ensure that the unit drive matches

the duct static pressure using Tables 19-31.

Fig. 67 — Evaporator-Fan Alignment

and Adjustment

CENTER DRIVE

SHAFT

FLEX

MEMBER

SHAFT

FLANGE

BEARINGSSHAFT

Fig. 68 — Evaporator Fan Coupling