89

If a Y2 (or Y2_SPT) call begins while the unit was under

“Y1 cooling” control, compressor no. 2 will not be started until

“Y1 cooling” control has ended.

If the Y2 (or Y2_SPT) call ends, with compressor 1 in an

unloaded state and compressor 2 ON, then compressor 1 will

be immediately brought up to the fully loaded state. If however,

the Y2 (or Y2_SPT) call ends, with compressor 1 in an unload-

ed state and compressor 2 OFF, then compressor 1 will be left

in its unloaded state. In either case the compressor 1 will be

loaded/unloaded as appropriate to the “Y1 Low Limit”.

The control shall lockout compressors if SAT becomes too

low and an alarm shall be issued.

Compressor no. 1 lockout at SAT < 53 F.

Compressor no. 2 lockout at SAT < 48 F.

If SAT sensor fails the control will energize compressor

no. 1 fully loaded (unloaders off), whenever there is a Y1 (or

Y1_SPT) call. Compressor no. 2 will be energized whenever

there is a call for Y2 (or Y2_SPT).

NOTE: When a VAV unit with software version 4.0 and later is

configured to operate from a space thermostat (VVT® relay

pack) or a space sensor, compressors start loaded and then

unload as needed. This is the opposite of the normal VAV

unloading sequence. When operating from supply-air tempera-

ture (SAT) sensor, VAV units will unload in the reverse

sequence.

FIELD TEST — The field test program is initiated by moving

up DIP switch no. 4 to the OPEN position. The outdoor-air

damper will close. The control allows 90 seconds for the damp-

er to close in case it was in the full open position. Next, the

indoor-fan contactor will be energized, and the outside-air

damper will begin to open to its default value of 20% and stay

at that position for a short period of time. The outdoor-air

damper will then open to its full open position and stay at that

position for a short period of time. The outdoor-air damper will

then close.

If the unit is equipped with power exhaust, stage 1 will be

energized for 5 seconds. If the unit is configured for stage 2 of

power exhaust, stage 2 will be energized for 5 seconds after the

first stage is deenergized.

The first stage of heat will be energized for 30 seconds, after

which the second stage heat will be energized for an additional

30 seconds. Heat is then deenergized.

The last step is the Cooling mode. Outdoor-fan contactor

no. 1 is energized. This is followed by each stage of cooling

energized with a 10-second delay between stages. After this

is complete, outdoor-fan contactor no. 2 is energized for

10 seconds.

The compressors will now deenergize, followed by the out-

door-fan contactors and indoor-fan contactors. If the unit is

equipped with the Integrated Gas Control (IGC) board, the in-

door fan will continue to operate for an additional 30 seconds

after deenergizing the circuit.

The field test is then complete.

SERVICE

Service Access —

All unit components can be reached

through clearly labelled hinged access doors. These doors are

not equipped with tiebacks, so if heavy duty servicing is need-

ed, either remove them or prop them open to prevent accidental

closure.

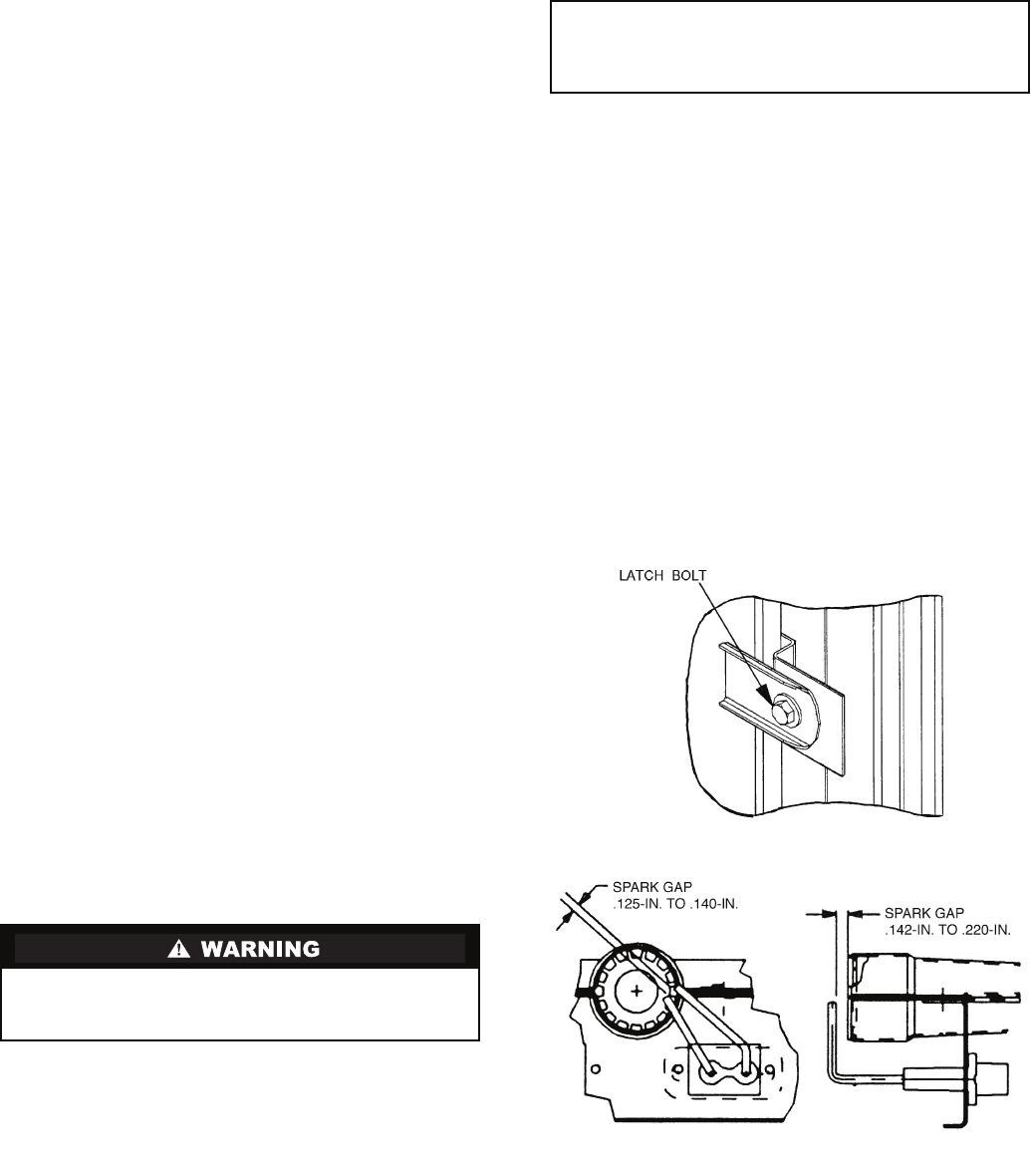

Each door is held closed with 3 latches. The latches are se-

cured to the unit with a single

1

/

4

-in. - 20 x

1

/

2

-in. long bolt. See

Fig. 63.

To open, loosen the latch bolt using a

7

/

16

-in. wrench. Pivot

the latch so it is not in contact with the door. Open the door. To

shut, reverse the above procedure.

NOTE: Disassembly of the top cover may be required under

special service circumstances. It is very important that the ori-

entation and position of the top cover be marked on the unit

prior to disassembly. This will allow proper replacement of the

top cover onto the unit and prevent rainwater from leaking into

the unit.

Cleaning — Inspect unit interior at beginning of each heat-

ing and cooling season and as operating conditions require.

Remove unit side panels and/or open doors for access to unit

interior.

MAIN BURNERS — At the beginning of each heating sea-

son, inspect for deterioration or blockage due to corrosion or

other causes. Observe the main burner flames and adjust if nec-

essary. Check spark gap. See Fig. 64. Refer to Main Burners

section on page 94.

FLUE GAS PASSAGEWAYS — The flue collector box and

heat exchanger cells may be inspected by removing gas section

access panel (Fig. 5-16), flue box cover, collector box, and

main burner assembly (Fig. 65 and 66). Refer to Main Burners

section on page 94 for burner removal sequence. If cleaning is

required, clean all parts with a wire brush. Reassemble using

new high-temperature insulation for sealing.

COMBUSTION-AIR BLOWER — Clean periodically to as-

sure proper airflow and heating efficiency. Inspect blower

wheel every fall and periodically during heating season. For the

first heating season, inspect blower wheel bi-monthly to deter-

mine proper cleaning frequency.

Before performing service or maintenance operations on

unit, turn off main power switch to unit. Electrical shock

could cause personal injury.

IMPORTANT: After servicing is completed, make sure

door is closed and relatched properly, and that the latches

are tight. Failure to do so can result in water leakage into

the evaporator section of the unit.

Fig. 63 — Door Latch

Fig. 64 — Spark Gap Adjustment