64

• DIP switch 6 configures the Time Guard® override and,

when used with the field test function, sets the minimum

damper position

• DIP switch 7 configures the unit for gas heat or electric

heat

• DIP switch 8 configures the unit for heat pump or air

conditioner operation.

Crankcase Heater — Units are equipped with crank-

case heaters. Crankcase heaters are energized as long as there is

power supplied to unit. Crankcase heaters deenergize while

compressors are running.

Evaporator Fan — Fan belt and fixed pulleys are

factory-installed. See Tables 19-33 for fan performance and

motor limitations data. Remove tape from fan pulley, and be

sure that fans rotate in the proper direction. See Table 34 for air

quantity limits. Static pressure drop for power exhaust is negli-

gible. To alter fan performance, see Evaporator Fan Perfor-

mance Adjustment section on page 91.

Condenser Fans and Motors — Condenser fans and

motors are factory set. Refer to Condenser-Fan Adjustment

section on page 92 as required. Be sure that fans rotate in the

proper direction. Fan no. 2 (48AJ,AK,AW,AY020-030 and

48EJ,EK,EW,EY024-034), fans no. 3 and 4 (48AJ,AK,AW,

AY035-050 and 48EJ,EK,EW,EY038-054), and fans no. 4, 5,

and 6 (48AJ,AK,AW,AY060 and 48EJ,EK,EW,EY058-068)

are cycled on the outdoor-air temperature.

The VFD will always provide the proper phase sequence to

the indoor-fan motor to operate in the proper rotation regard-

less of the phase sequence to the unit. If on start-up, the outdoor

fans operate backwards but the indoor fan operates in the cor-

rect direction, reverse any two leads to the unit main terminal

block and all fans will operate in the correct direction.

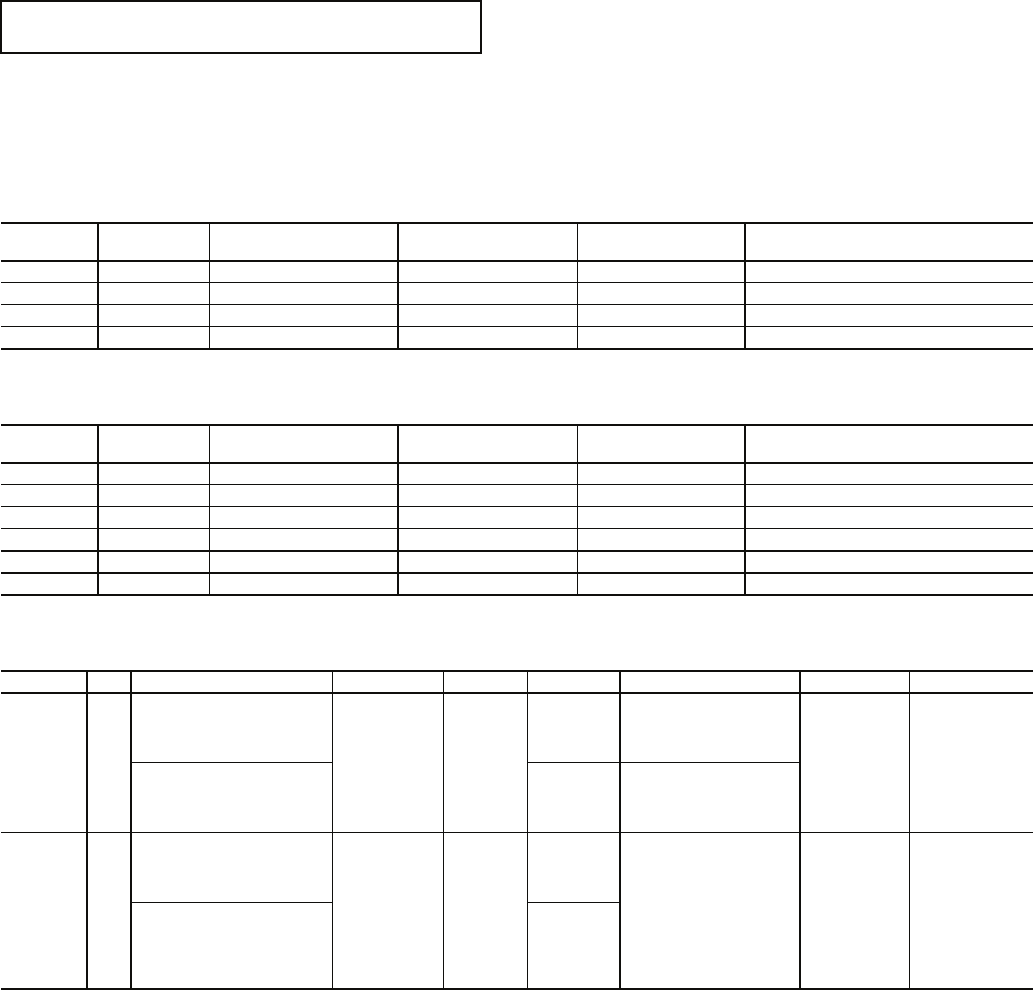

Table 16A — Power Exhaust Default Set Points (48AJ,AK,AW,AY020-050 and 48EJ,EK,EW,EY024-048)

Table 16B — Power Exhaust Default Set Points (48AJ,AK,AW,AY060 and 48EJ,EK,EW,EY054-068)

Table 17 — DIP Switch Configuration

LEGEND

NOTES:

1. The OPEN side of the DIP switch is marked ‘‘OPEN.’’ When the

rocker switch is on the ‘‘OPEN’’ side of the switch, the switch is

OPEN.

2. The configuration of DIP switches 2 and 5 are dependent on

DIP switch 1. If DIP switch 1 is set to OPEN (VAV operation),

then DIP switches 2 and 5 will configure VAV functions.

3. When the unit is field-tested (DIP switch 4 to OPEN), the func-

tion of DIP switch 6 changes and it is used to set the minimum

damper position.

4. Recycle power to unit after modifying DIP switches. This will

allow the unit to access the new configurations and update its

tables.

IMPORTANT: To prevent damage to compressors, crank-

case heater should be energized 24-hours prior to start-up.

STAGE OFFSET DIFFERENTIAL OFF VOLTAGE ON VOLTAGE

OFF STATIC PRESSURE

(in.wg)

1 50% 3% 6.0 6.3 0.00

2 55% 3% 6.5 6.8 0.06

3 60% 3% 7.0 7.3 0.12

4 64% 3% 7.4 7.7 0.18

STAGE OFFSET DIFFERENTIAL OFF VOLTAGE ON VOLTAGE

OFF STATIC PRESSURE

(in.wg)

1 50% 3% 6.0 6.3 0.00

2 55% 3% 6.5 6.8 0.06

3 60% 3% 7.0 7.3 0.12

4 65% 3% 7.5 7.8 0.19

5 70% 3% 8.0 8.3 0.25

6 75% 3% 8.5 8.8 0.31

SETTING 1 2 3 4 5 6 7 8

OPEN VAV

VAV — Space Sensor

Installed

Expansion

Board

Field Test

ON

VAV —

Occupied

Heat

Enabled

Time Guard® Override

ON

Gas Heat

Heat Pump

Operation

CV — CCN or Sensors

Used

CV —

Modulated

Power

Exhaust

IN CONJUNCTION

WITH FIELD TEST

— Set Minimum

Damper Position

CLOSED CV

VAV — No Space Sensor

Base Control

Board Only

Field Test

OFF

VAV —

Occupied

Heat

Disabled

Time Guard Override

OFF

Electric Heat

Air Conditioner

Operation

CV — Thermostat

CV —

Constant

Volume

Power

Exhaust

CCN — Carrier Comfort Network

CV — Constant Volume

VAV — Variable Air Volume