52

7. Route the wires from the enthalpy sensor to the return air

enthalpy control through the holes on the inside of the

hinged filter access panel. The holes are blocked by plug

buttons which should be removed.

8. Use field-supplied wire ties to attach the violet wire to the

+ terminal and the blue wire to the SR terminal.

9. Replace economizer filters.

10. Return power to unit.

Disable Economizer

— For applications where the economiz-

er will not be used (areas of high humidity), the economizer

should be disabled. To disable the economizer, perform the

following:

1. Turn of power. Ensure disconnect is locked out.

2. Locate the OAT (Outdoor Air Thermostat) in the right

hand outdoor air damper area.

3. Locate the splice connecting the violet wire coming from

T24 on the base control board to the red wire coming

from T29 on the base control board. Remove the wire nut

and break the red to violet wire splice.

4. Cap off both wires. When the connection is broken the

base control board is fooled into thinking that the

enthalpy is not acceptable and economizer operation is

disabled.

5. Return power to unit.

NOTE: When the economizer is disabled, the damper

will function as a 2-position damper.

Step 11 — Position Power Exhaust/Barometric

Relief Damper Hood —

All electrical connections have

been made and adjusted at the factory. The power exhaust

blowers and barometric relief dampers are shipped assembled

and tilted back into the unit for shipping. Brackets and extra

screws are shipped in shrink wrap around the dampers. If

ordered, each unit will have 4 (48AJ,AK,AW,AY020-050 and

48EJ,EK,EW,EY024-048 units) or 6 (48AJ,AK,AW,AY060

and 48EJ,EK,EW,EY054-068 units) power exhaust blowers

and motors or 4 (48AJ,AK,AW,AY020-050 and 48EJ,EK,EW,

EY024-048 units) or 6 (48AJ,AK,AW,AY060 and 48EJ,EK,

EW,EY054-068 units) barometric relief dampers.

1. Remove 9 screws holding each damper assembly in

place. See Fig. 50. Each damper assembly is secured with

3 screws on each side and 3 screws along the bottom.

Save screws.

2. Pivot each damper assembly outward until edges of

damper assembly rest against inside wall of unit.

3. Secure each damper assembly to unit with 6 screws

across top (3 screws provided) and bottom (3 screws

from Step 1) of damper.

4. With screws saved from Step 1, install brackets on each

side of damper assembly.

5. Remove tape from damper blades.

VAV DUCT PRESSURE TRANSDUCER — The VAV duct

pressure transducer (VAV inverter pressure transducer) is locat-

ed behind the filter access door on the lower inner panel. See

Fig. 51. A section of field-supplied

1

/

4

-in. plastic tubing must

be run from the high pressure tap on the differential pressure

switch and connected to a field-supplied tap in the supply-air

duct. The tap is usually located

2

/

3

of the way out on the main

supply duct. Remove plug button in panel to route tubing.

VAV BUILDING PRESSURE TRANSDUCER — The VAV

building pressure transducer (modulating power exhaust pres-

sure transducer) is located behind the filter access door on the

lower inner panel. See Fig. 51. A section of field-supplied

1

/

4

-in. plastic tubing must be run from the high pressure tap on

the differential pressure switch to the conditioned space. The

pressure tube must be terminated in the conditioned space

where a constant pressure is required. This location is usually

in an entrance lobby so that the building exterior doors will

open and close properly. Remove plug button in panel to route

tubing.

The low pressure tap is factory-routed to the atmosphere.

For a positive-pressure building, route the high tap to building

air and low tap to atmosphere. For a negative-pressure build-

ing, route the high tap to atmosphere and the low tap to build-

ing air.

Be careful when tilting blower assembly. Hoods and blow-

ers are heavy and can cause injury if dropped.

+

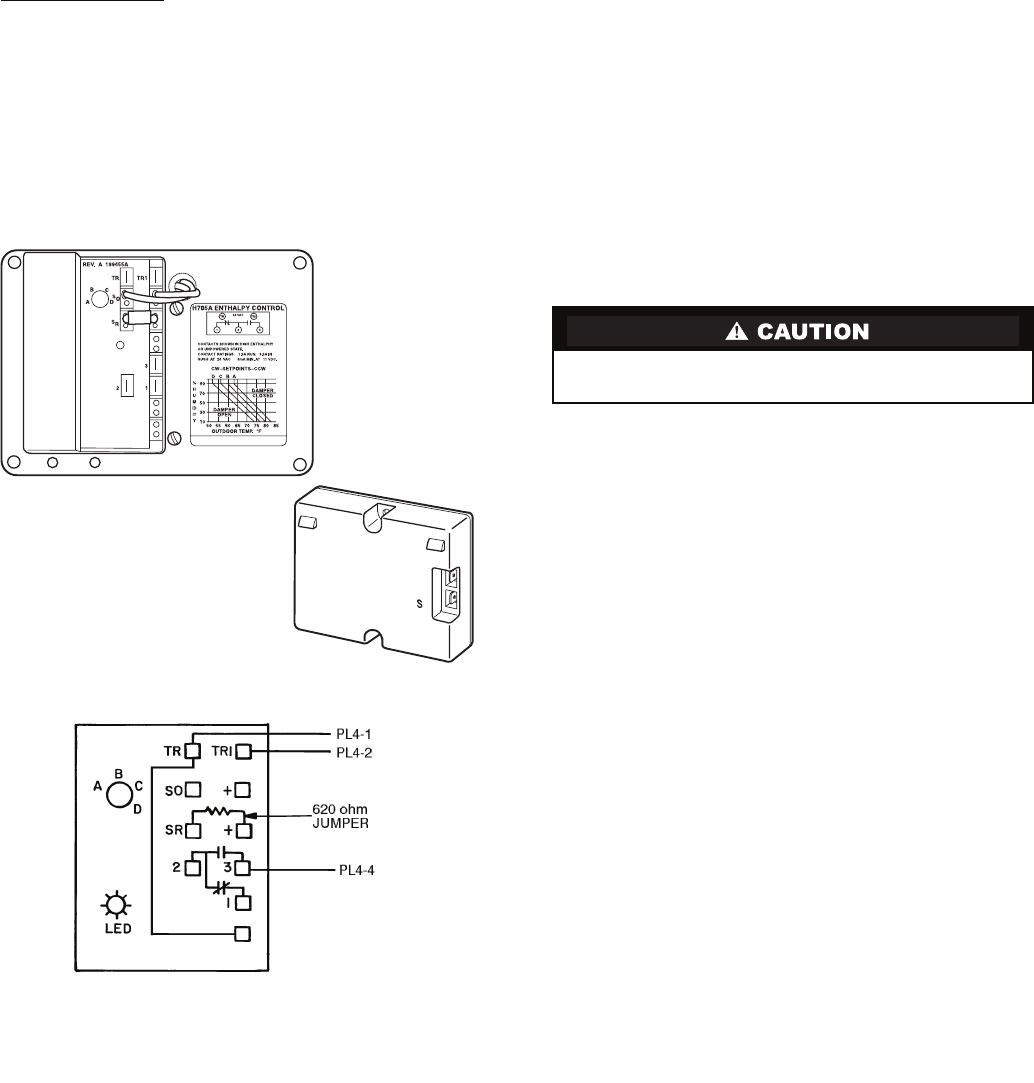

C7400A1004

HH57AC077

ENTHALPY

CONTROL

HH57AC078

ENTHALPY SENSOR

(USED WITH ENTHALPY

CONTROL FOR DIFFERENTIAL

ENTHALPY OPERATION)

Fig. 46 — Differential Enthalpy Control and Sensor

NOTE: Switches shown in high enthalpy state. Terminals 2 and 3

close on enthalpy decrease.

Fig. 47 — Wiring Connections for Solid-State

Enthalpy Control (HH57AC077)