14

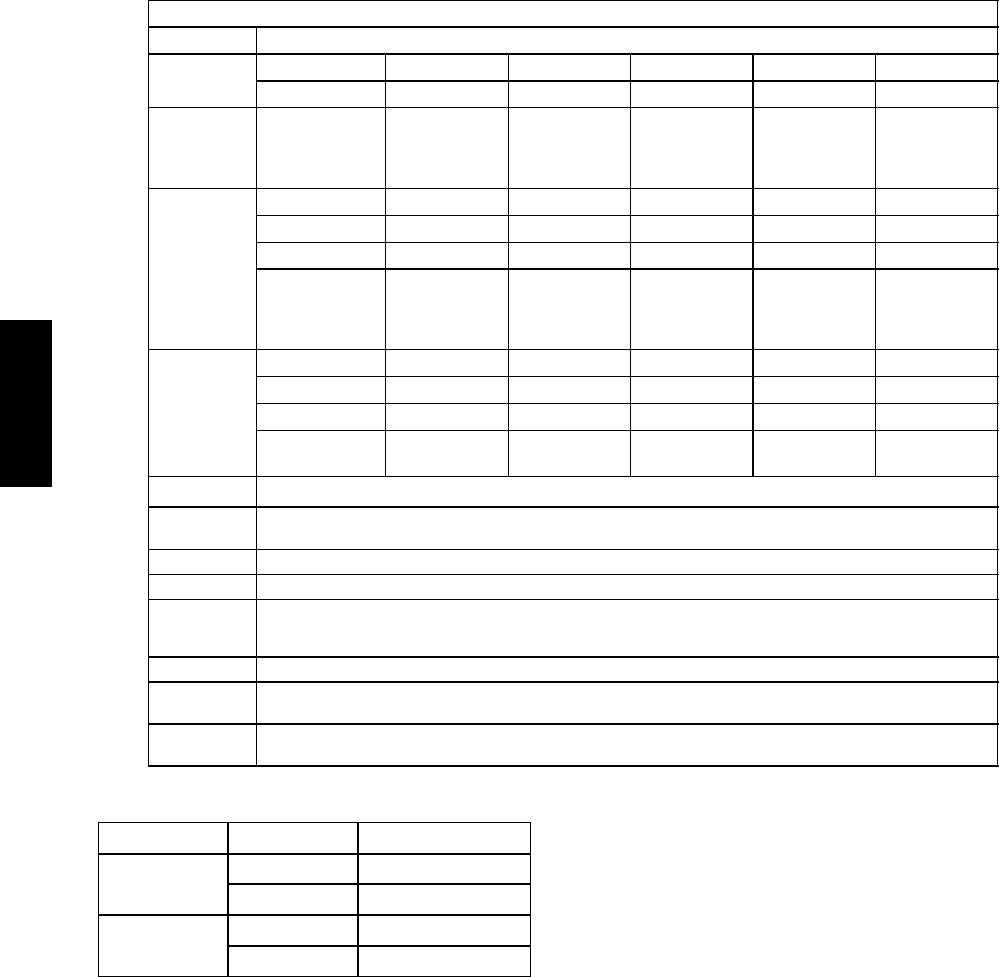

Table 6 – 38AUD 16-25 Piping Recommendations (Two-Circuit Unit)

NOTE: 38AUD requires TWO sets of refrigeration piping

R -410A Equivalent Length

Ft 0-38 38-75 75-113 113-150 150-188

m 0-12 12-23 23-34 34-46 46-57

Model

Linear Length

Ft 0-25 25-50 50-75 75-100 100-125

m 0-8 8-15 15-23 23-30 30-38

38AUD*16 Liquid Line

1

/

2

1

/

2

1

/

2

1

/

2

1

/

2

Max Lift 25 50 75 100 125

Suction Line

7

/

8

1

1

/

8

1

1

/

8

1

1

/

8

1

1

/

8

Charge ea. (lbs)

Novati on 11.7 13.8 15.7 17.6 19.6

RTPF 21.7 23.8 25.7 27.6 29.6

38AUD*25 Liquid Line

1

/

2

1

/

2

1

/

2

5

/

8

1

/

2

5

/

8

1

/

2

5

/

8

Max Lift 25 50 54 75 60 99 46 95

Suction Line 1

1

/

8

1

1

/

8

1

1

/

8

1

1

/

8

1

3

/

8

1

3

/

8

Charge (lbs) 1

2

19.3

18.3

21.0

20.3

23.0

22.0

26.0

25.0

25.9

24.9

29.7

28.7

28.0

27.0

32.7

31.7

Legend:

Equivalent

Length

Equivalent tubing length, including effects of refrigeration specialties devices

Linear Length Typical linear tubing length (50% added to linear to define Equivalent Length for this table)

Liquid Line Tubing size, inches OD.

Max Lift Maximum liquid lift (indoor unit ABOVE outdoor unit only), at maximum permitted liquid line pressure drop —

S Linear Length Lessthan 75 ft (23 m): Minimum 2.0°F subcooling entering TXV

S Linear Length Greater than 75 ft(23m): Minimum 0.5°F subcooling entering TXV

Suction Line Tube size, inches OD

Charge Charge Quantity, lbs. Calculated for both liquid line sizes (where applicable), but only with larger suction line size

(where applicable)

NOTE: For applications with equivalent length greater than 188 ft (57 m) and/0r linear length greater than 125 ft (38 m),

contact your local Bryant representative.

Table 7 – 38AU Maximum Suction Pipe Size

Model: Unit Size Maximum Tube Size

38AUZ

16 1

5

/

8

25 1

5

/

8

38AUD

16 1

5

/

8

25 1

5

/

8

Vertical Separation (outdoor unit above indoor unit) –

Vertical elevation difference of 200 ft (60 m) is permitted

when the outdoor unit (38AUZ or 38AUD) is located

above the indoor unit.

Insulate Suction Lines —

Apply closed-cell tubular insulation to all suction lines

between evaporator coil connection and 38AU unit’s

suction service valve.

Hot Gas Bypass —

Hot gas bypass, if used, should be introduced before the

evaporator. (A bypass route that also bypasses the evaporator

circuit may lead to oil trapping in the evaporator circuit

during low load conditions and then to oil slugging as

evaporator load increases.) Model 38AU units do not include

a hot gas stub connection; a tee must be field-supplied and

installed in the compressor discharge line. Run a

1

/

2

-in OD

line between outdoor unit and evaporator coil inlet. Install an

Auxiliary Side Connector at the evaporator between TXV

and distributor (follow instructions for the side connector

part). Insulate the hot gas line.

38AUD: Generally only one hot gas bypass system will be

applied on a two-circuit unit. Connect the hot gas bypass

system to Circuit 1 (first-on/last-off, connected to the

evaporator coil’s bottom circuit).

38AUD Piping Connections —

The 38AUD’s two circuits are designated Circuit 1 and

Circuit 2. Circuit 1 is controlled by the thermostat’s Y1 (or

TC1) contact and will be the first circuit on and last circuit

off. Circuit 2 is controlled by the thermostat’s Y2 (or TC2)

contact and this circuit is always the “lag” circuit.

See Fig. 6 for location of Circuit 1 and Circuit 2 service

valves and field piping connections. Circuit 1 is on the

left-hand side of the service valve compartment; Circuit 2

is on the right.

When a single piece evaporator coil with two separate

circuits is connected to a 38AUD, the lower coil circuit

should be connected to the 38AUD’s Circuit 1 so that the

evaporator’s lower coil segment is first-on/last-off (to avoid

re-evaporation of condensate on dry lower coil segments).

38AU