25

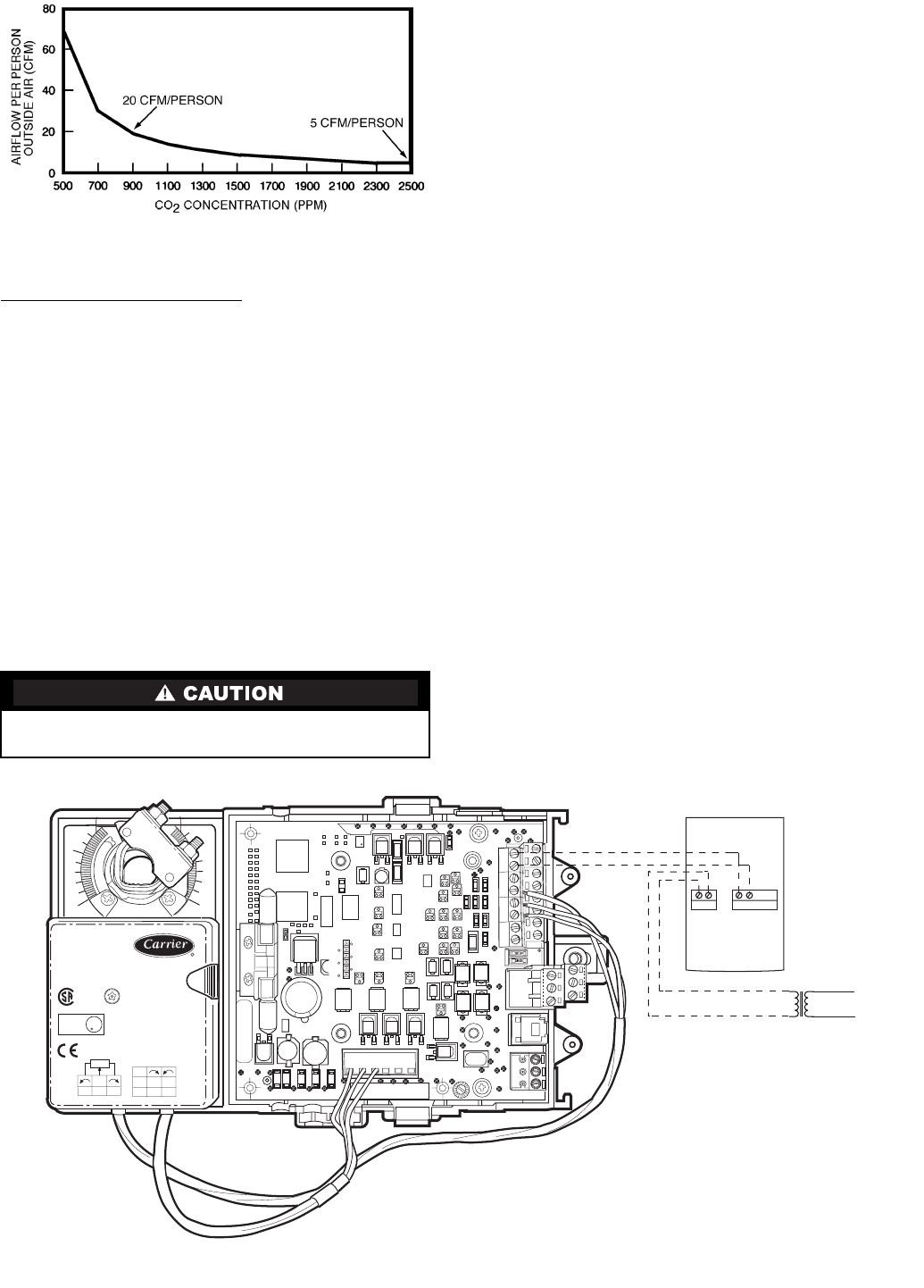

Indoor Air Quality Sensor Wiring

— To wire the sensors

after they are mounted in the conditioned air space and return

air duct, see Fig. 20 and the instructions shipped with the sen-

sors. For each sensor, use two 2-conductor 18 AWG twisted-

pair cables (unshielded) to connect the separate isolated 24 vac

power source to the sensor and to connect the sensor to the con-

trol board terminals. To connect the sensor to the control board,

identify the positive (+) PIN-8 and ground (GND) PIN-7 termi-

nals on the sensor and connect the positive terminal to terminal

RH/IAQ and connect the ground terminal to terminal GND.

HUMIDITY SENSOR (WALL-MOUNTED) INSTALLA-

TION — The accessory space humidity sensor is installed on

an interior wall to measure the relative humidity of the air with-

in the occupied space. See Fig. 21.

The use of a standard 2- x 4-in. electrical box to accommo-

date the wiring is recommended for installation. The sensor can

be mounted directly on the wall, if acceptable by local codes.

If the sensor is installed directly on a wall surface, install the

humidity sensor using 2 screws and 2 hollow wall anchors

(field-supplied); do not overtighten screws. See Fig. 11.

The sensor must be mounted vertically on the wall. The

Carrier logo should be oriented correctly when the sensor is

properly mounted.

DO NOT mount the sensor in drafty areas such as near heat-

ing or air-conditioning ducts, open windows, fans, or over heat

sources such as baseboard heaters, radiators, or wall-mounted

light dimmers. Sensors mounted in those areas will produce in-

accurate readings.

Avoid corner locations. Allow at least 4 ft between the sen-

sor and any corner. Airflow near corners tends to be reduced,

resulting in erratic sensor readings.

Sensor should be vertically mounted approximately 5 ft up

from the floor, beside the space temperature sensor.

For distances up to 500 feet, use a 3-conductor, 18 or 20

AWG cable. A CCN communication cable can be used,

although the shield is not required. The shield must be removed

from the sensor end of the cable if this cable is used. See

Fig. 22 for wiring details.

The power for the sensor is provided by the control board.

The board provides 24 vdc for the sensor. No additional power

source is required.

To wire the sensor, perform the following:

1. At the sensor, remove 4-in. of jacket from the cable.

Strip

1

/

4

-in. of insulation from each conductor. Route

the cable through the wire clearance opening in the

center of the sensor. See Fig. 22.

2. Connect the RED wire to the sensor screw terminal

marked (+).

3. Install one lead from the resistor (supplied with the

sensor) and the WHITE wire, into the sensor screw ter-

minal marked (–). After tightening the screw terminal,

test the connection by pulling gently on the resistor

lead.

4. Connect the remaining lead from the resistor to the

BLACK wire and secure using a closed end type crimp

connector or wire nut.

5. Using electrical tape, insulate any exposed resistor

lead to prevent shorting.

6. At the control box, remove the jacket from the cable

and route the RED conductor over to the left side of

the control board. Route the remaining conductors to

the right side of the control board.

Do NOT clean or touch the sensing element with chemical

solvents; they can permanently damage the sensor.

Fig. 19 — Ventilation Rated Based on

CO

2

Set Point

35 in-lb (4 Nm)

80...110s

HF23BJ042

Made in Switzerland

by Belimo Automation

1

0

yel

blu

ora

WIP

5K

LISTED

94D5

TEMP. IND. &

REG. EQUIP.

U

L

Class 2 Supply

LR 92800

NEMA 2

24VAC/DC

50/60Hz

3VA 2W

COM

1

2

3

blk

red

wht

LINE

VOLTAGE

87

21

24 VAC

RH/IAQ

GND

SEPARATE

ISOLATED

POWER

SUPPLY

REQUIRED

(24 VAC, 25 VA

MINIMUM)

*

Do not connect to the same transformer that supplies power to the zone controller.

→

Fig. 20 — Indoor Air Quality Sensor Wiring

303