13

Status Codes

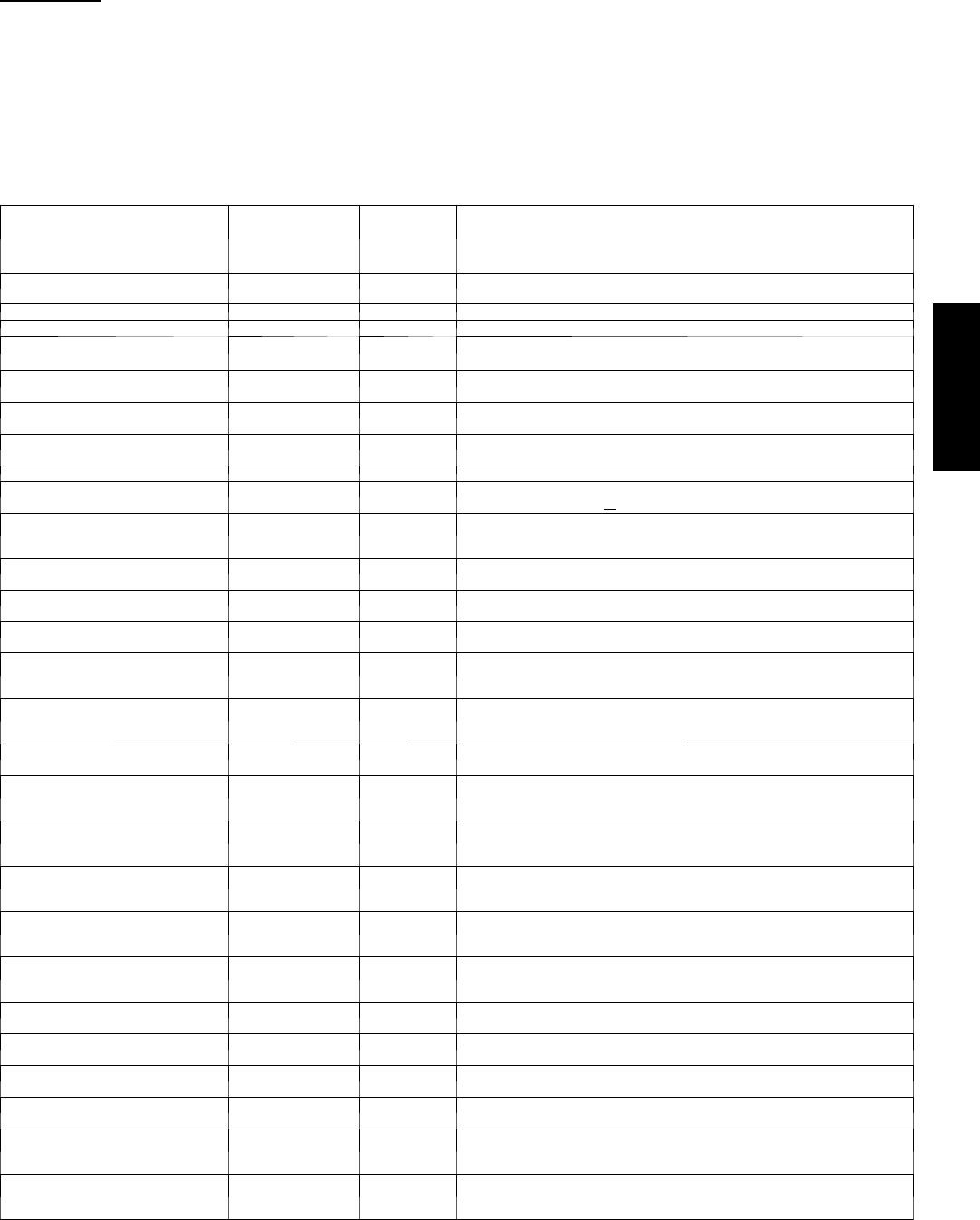

Table 6 shows the status codes flashed by the amber status light.

Most system problems can be diagnosed by reading the status code

as flashed by the amber status light on the control board.

The codes are flashed by a series of short and long flashes of the

status light. The short flashes indicate t he first digit in the status

code, followed by long flashes indicating the second digit of the

error code. The short flash is 0.25 seconds ON and the long flash

is 1.0 second ON. Time between flashes is 0.25 seconds. Time

between short flash and first long flash is 1.0 second. Time

between code repeating is 2.5 seconds with LED OFF.

Count the number of short and long flashes to determine the

appropriate flash code. Table 6 gives possible causes and actions

related to each error .

EXAMPLE:

3 short flashes followed by 2 long flashes indicates a 32 code.

Table 6 shows this to be low pressure switch open.

Table 6 – TROUBLESHOOTING

OPERATION

FAUL T

AMBER

LED

FLASH

CODE

POSSIBLE CAUSE AND ACTION

Standby – no call for unit operation None

On solid, no

flash

Normal operation

low---stage Cool/Heat Operation None 1, pause Normal operation

high---stage Cool/Heat Operation None 2, pause Normal operation

System Commu-

nications Failure

16 Communication with user interface lost. Check wiring to User Interface,

indoor and outdoor units

Invalid Model Plug 25

Control does not detect a model plug or detects an invalid model plug. Unit

will not operate without correct model plug.

High Pressure

Switch Open

31*

High---pressure switch trip. Check refrigerant charge, outdoor fan operation

and coils for airflow restrictions.

Low Pressure

Switch Open

32* Low pressure switch trip. Check refrigerant charge and indoor air flow

Control Fault 45 Outdoor unit control board has failed. Control bo ard needs to be replaced.

Brown Out (230 v) 46

Line voltage < 187v for at least 4 seconds. Compressor and fan operation

not allowed until voltage>

190v. Verify line voltage.

No 230v at Unit 47

There is no 230v at the contactor when indoor unit is powered and cooling/

heating demand exists. Verify the disconn ect is closed and 230v wiring is

connected to the unit.

Outdoor Air Temp

Sensor Fault

53

Outdoor air sensor not reading or out of ran ge. Ohm out sensor and check

wiring.

Outdoor Coil Sen-

sor Fault

55 Coil sensor not reading or out of range. Ohm out sensor and check wiring.

Thermistors out of

range

56

Improper rela tionship between coil sensor and outdoor air sensor. Ohm out

sensorsand check wiring.

low ---stage Ther-

mal Cutout

71*

Compressor o peration detected then disappears while low---stage demand

exists. Possible causes are internal compressor overload trip or start relay

and capacitor held in circuit too long(if installed)

high---stage Ther-

mal Cutout

72*

Compressor o peration detected then disappears while high---stage demand

exists. Possible causes are internal compressor overload trip or start relay

and capacitor held in circuit too long (if installed)

Contactor Shorted 73

Compressor voltage se nsed when no demand for compressor operation

exists. Contactor m ay be stuck closed or th ere is a wiring error.

No 230V at Com-

pressor

(24ANA1 Only)

74

Compressor voltage not sensed when compressor should be starting. Con-

tactor may be stuck open or there is a wiring error.

low ---stage Did Not

Start

(24ANA7 Only)

75

Specified start voltage at VR terminal was not achieved in low---stage. Start

relay was de---energized after 1 second.

low ---stage Did Not

Start 3 times

(24ANA7Only)

76

For 3 consecutive low---stage starts, the specified start voltage at VR terminal

was not achieved & start rela y was de---energized. low---stage locked out for

30 minutes.

high ---stage Did

Not Start

(24ANA7 Only)

77

Specified start voltage at VS t erminal w as not achieved in high---stage. Start

relay was de---energized after 1 second.

high ---stage Did

Not Start 3 times

(24ANA7 Only)

78

For 3 consecutive hi g h---stage starts, the specified start voltage at VS termi-

nal was not achieved & start relay was de---energized. high---stage locked

out for 30 minutes.

low ---stage Ther-

mal Lockout

81

Thermal cutout occurs in t hree consecutive low/ high---stage cycles. low---

stage locked out for 4 hours or until 24v power recycled.

high---stage Ther-

mal Lockout

82

Thermal cutout occurs in three consecutive high/low---stage cycles. high---

stage locked out for 4 hours or until 24v power recycled.

Low Pressure

Lockout

83

Low pressure switch trip has occurred during 3 c onsecutive c ycles. Unit

operation locked out for 4 hours or until 24v power recycled.

High Pressure

Lockout

84

High p ressure switch trip has occurred during 3 c onsecutive c ycles. Unit

operation locked out for 4 hours or until 24v power recycled.

Low Contactor

Open

(24ANA7 Only)

85

Compressor voltage not sensed when compressor should be starting. low---

stage contactor may be stuck open or there is a wiring error.

High Contactor

Open

(24ANA7 Only)

87

Compressor voltage not sensed when compressor should be starting. high---

stage contactor may be stuck open or there is a wiring error.

* Sequence: Compressor contactor is de---energized and outdoor fan is energized for up to 15 minu tes. If demand still exists, control will energize compressor

contactor after 15 minute delay. If fault is cleared, unit will resume operation. If fault still exists, fan shuts off, and error code continues to flash. Control will

attempt re---start every 15 minutes. Cycling low voltage defeats the 15 minute delay.

24ANA