67

b. Locate oil pressure adjusting screw and turn

screw to obtain proper pump pressure, refer to

Table 6 at rear of manual.

c. To check the cutoff pressure, deadhead a reliable

pressure gauge onto the copper connector tube

attached to the nozzle port. Run the burner for

a short period of time. Shut the burner off. The

pressure should drop and hold.

d. Remove the gauge and install bleeder port and/or

reconnect the nozzle port line.

G. ADJUST OIL BURNER WHILE OPERATING.

(fl ame present)

1. ADJUST DRAFT REGULATOR for a draft of

— .02” (water gauge) over the fi re after chimney has

reached operating temperature and while burner is

running.

2. READJUST THE AIR BAND on burner for

a light orange colored fl ame while the draft over

the fi re is —.02”. Use a smoke tester and adjust

air for minimum smoke (not to exceed #1) with a

minimum of excess air. Make fi nal check using

suitable instrumentation to obtain a CO

2

of 11.5 to

12.5% with draft of —.02” (water gauge) in fi re

box. These settings will assure a safe and effi cient

operating condition. If the fl ame appears stringy

instead of a solid fi re, try another nozzle of the same

type. Flame should be solid and compact. After all

adjustments are made recheck for a draft of —.02”

over the fi re.

3. READJUST THE HEAD SETTING only if

necessary.

Beckett Burners

a. V82 & V83:

Beckett MB(L1) Head burners have a fi xed head

which are non-adjustable.

b. V84 thru V89:

Beckett MD(V1) (variable) Head burners have

the ability to control air by moving the head. It

might be necessary to move the head forward

or back one position at a time to optimize the

smoke and CO

2

readings. See Figure 27A.

Carlin 102CRD Burners

a. V87 through V89

The Carlin 102 CRD-3 Burner has the ability

to control air by moving the head. It might be

necessary to move the head forward or back one

position at a time to optimize the smoke and

CO2 readings.

b. If the fi re is a little too rich, move the

combustion head slightly forward by increasing

dimension “A”. Refer to Figure 27B.

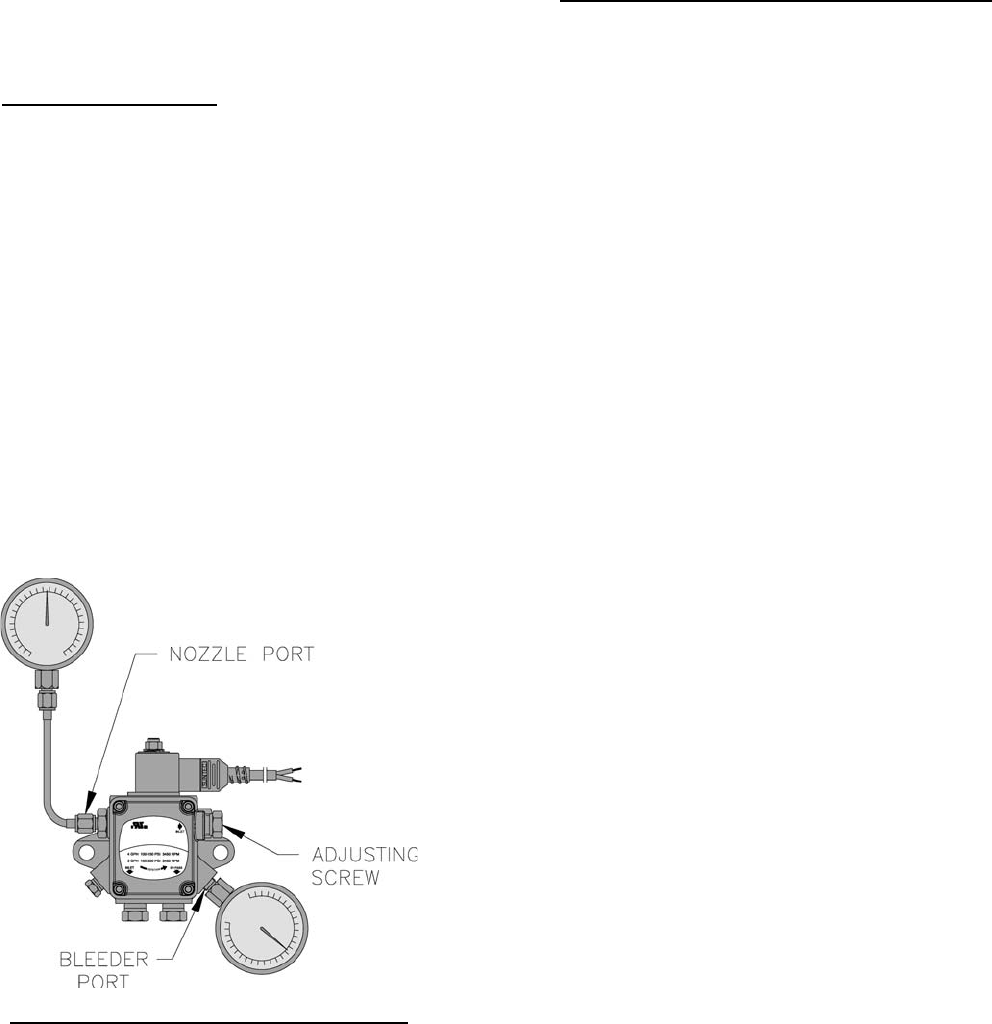

Figure 26: Adjusting Fuel Pump Pressure

2) change the factory air settings according to

Table 6 and,

3) check the oil pump pressure and adjust if

necessary to the setting specifi ed in Table 6,

refer to Paragraph F for details.

5. Riello Burners

a. OPEN ALL OIL LINE VALVES.

b. Provide a pan to catch oil.

c. Remove pressure port/bleeder plug from fuel

pump and install Riello Combination Pressure

Gauge and Bleeder Valve Assembly.

d. OPEN FLAME OBSERVATION PORT COVER

on burner swing door.

F. START OIL BURNER.

1. Open vent fi tting on fuel pump.

2. TURN ‘ON’ BURNER service switch and

allow burner to run until oil fl ows from vent

fi tting in a SOLID stream without air bubbles for

approximately 10 seconds.

3. Close vent fi tting and burner fl ame should start

immediately after prepurge is completed. Prepurge

prevents burner fl ame until 10 seconds has elapsed

after initial power is applied to burner. During

prepurge the motor and igniter will operate but the

oil valve will remain closed. Refer to Oil Primary

Control Instructions for more details.

4. Adjust oil pressure.

a. When checking a fuel unit's operating pressure, a

reliable pressure gauge may be installed in either

the bleeder port or the nozzle port. See Figure

26.