21

Riello manometers and vacuum gauges do not

require any adapters, and can be safely connected

to the pump ports. An NPT x metric adapter

must be used when connecting other gauge

models.

g. Replace Burner Cover and Tighten Burner Cover

Screws.

Water Boilers Only

Select the proper oil nozzle for the installation.

Burners for knockdown V8 water boilers are

shipped with the high (standard) input oil nozzle

installed in the burner.

A second oil nozzle for the lower (minimum)

fi ring rate is shipped loose for the V83 - V86

models, attached to the burner. Either nozzle

may be used with water boilers. The lower

(minimum) input nozzle will provide greater

boiler effi ciency. However, boiler output will be

reduced. Refer to Table 1B for fi ring rates. If

the higher rate is desired, inspect the installed

nozzle and assure that the nozzle is the correct

size and type as specifi ed in Table 6 of this

manual. The nozzle input is stamped on the hex

fl at of the nozzle.

If the lower (minimum) input is desired, remove

the nozzle which was factory installed. Locate

the lower (minimum) fi ring rate nozzle that is

supplied loose. Confi rm the nozzle is the proper

size and type for the lower fi ring rate as specifi ed

in Table 6 of this manual. Install the proper

nozzle in the burner nozzle adaptor.

Proceed to Step c for burner drawer assembly

removal.

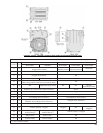

N. INSTALL TRIM AND CONTROLS WITH

BECKETT BURNER. - Steam Boiler Only (see

Figures 1D & 5).

1. Thread the pressure gauge into the ¼” NPT tapping

"B", of the front section. Tighten with wrench

applied to the square shank of the gauge.

NOITUAC

-esaceguagehtoterusserpylppatonoD

.sgnidaeretaruccaninitluseryamsiht

2. Thread 1½” NPT x ¾” NPT bushing and a ¾” NPT

drain valve into the 1½” NPT tapping located in the

lower right corner of the front section. Tighten with

wrench.

ECITON

rofdesusi"H"gnippaTnoitcesraerrewoL

maetsnonruteretasnednocdradnats

.sreliob

3. Thread safety valve, as shown in Figure 1D, into ¾"

NPT coupling and ¾” NPT x 8” nipple previously

installed in Paragraph H, No. 1, step b. Tighten

with wrench. Pipe discharge as shown in Figure

14. Installation of the safety (relief) valve must be

consistent with ANSI/ASME Boiler and Pressure

Vessel Code, Section IV.

GNINRAW

ebtsumgnipipegrahcsidevlavytefaS

folaitnetopetanimileotroolfraendepip

aeraynaniepiptonoD.snrubereves

lla

tsnitonoD.ruccodluocgnizeerferehw

.spacrosgulp,sevlavffo-tuhsyna

4. Install probe type Low Water Cut-Off (LWCO) if so

equipped.

GNINRAW

snoitcurtsnis’rerutcafunamehtdaeR

reporprofOCWLeborpehthtiwdekcap

nolfeTesuTONOD.noitacilppaepodepip

nac

nolfetfoesU.sdaerhteborpnoepat

.lanoitareponiOCWLeborpehtredner

a. Thread probe into ¾” NPT tapping "C" located

on the front section, down and to the right of

the pressure gauge. Slip the low water cut-off

(LWCO) control over the probe and clamp in

place. Connect the wire(s) between the probe and

control per the manufacturer’s instructions.

b. Install the gauge glass using the two ½” NPT

tappings to the right of the probe LWCO.

5. Install fl oat-type LWCO, if so equipped.

See Figure 8.

a. Install nipples and unions in "D" Tappings.

b. Mount hardware to low water cut-off body.

Install assembly.

c. Install water gage glass on low water cut-off

assembly's tee fi ttings.

6. Install Pressure Limit Control.

a. Float LWCO only: Remove ¼" NPT plug from

top of Low Water Cut-Off. Install Syphon and

Limit into this tapping. See Figure 8.

b. Probe LWCO only: Install Limit in Tapping "A"

using ¾" NPT x 3" long nipple, ¾" NPT elbow,

¾" NPT x ¼" NPT bushing, and syphon. See

Figure 9.

c. Do not tighten the limit by holding the case;

apply a wrench to the brass hex below the case.

d. Level an L404A pressure limit by carefully

bending the syphon until the limit's leveling

indicator hangs freely with its pointer directly

over the index mark inside the back of the case.