24

where conditions warrant) to fl ush out the sediment

chamber so the device will be free to function properly.

Low water fuel cutoffs and water feeders should be

dismantled annually by qualifi ed personnel, to the

extent necessary to insure freedom from obstructions

and proper functioning of the working parts. Inspect

connecting lines to boiler for accumulation of mud,

scale, etc. and clean as required. Examine all visible

wiring for brittle or worn insulation and make sure

electrical contacts are clean and that they function

properly. Give special attention to solder joints on

bellows and fl oat when this type of control is used.

Check fl oat for evidence of collapse and check mercury

bulb (where applicable) for mercury separation or

discoloration. Probe type low water cutoff should be

removed once a year, examined and cleaned of any

dirt accumulations to assure proper operation. Do not

attempt to repair mechanisms in the fi eld. Complete

replacement mechanisms including necessary gaskets

and installation instructions are available from the

manufacturer.

9 LUBRICATION

There are no parts requiring lubrication on the part of

the serviceman or the homeowner. Circulator bearings

are water lubricated. Fan motor bearings are factory

sealed.

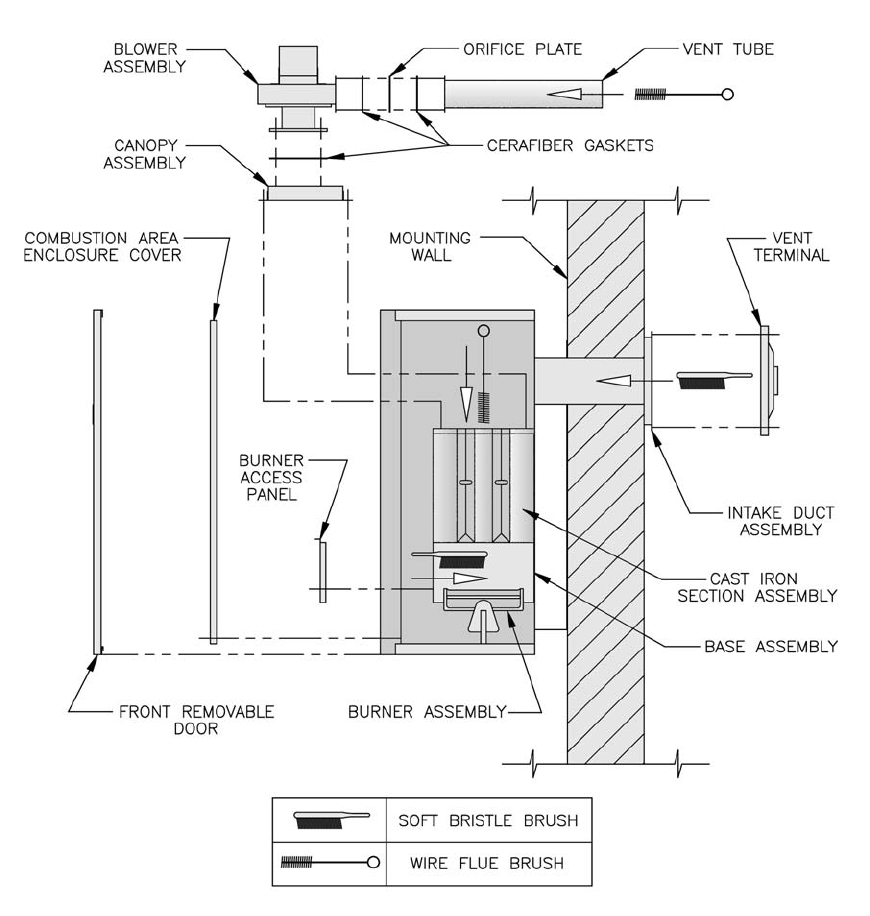

Figure 16

CLEANING OF VENT SYSTEM, BOILER FLUES, AND BURNERS